| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $138.39 | $135.56 | $131.33 | $125.68 | Contact US |

SS-BZ-TC Machining Center CNC Control Panel Lathe Control Panel For FANUC and Mitsubishi Systems

$361.94

SS-BZ-TC Machining Center CNC Control Panel Lathe Control Panel For FANUC and Mitsubishi Systems

$361.94

DDCS-EXPERT (DDCSE) 5-Axis CNC Offline Controller Motion Controller Support PWM Output Compatible with Standard G-code

$407.45

DDCS-EXPERT (DDCSE) 5-Axis CNC Offline Controller Motion Controller Support PWM Output Compatible with Standard G-code

$407.45

DDCS-EXPERT (DDCSE) 4-Axis CNC Offline Controller Motion Controller Support PWM Output Compatible with Standard G-code

$388.02

DDCS-EXPERT (DDCSE) 4-Axis CNC Offline Controller Motion Controller Support PWM Output Compatible with Standard G-code

$388.02

HQUDJ ER16 48V 400W Air Cooled Brushless Spindle Motor + Closed Loop Driver for Engraving Automation

Features of Brushless Motor:

- Brushless with low interference. There is no electric spark generated when the brushless motor is running, which greatly reduces the interference of the electric spark on the remote control radio equipment

- Low noise and smooth operation. It facilitates the stable operation of equipment

- Long service life and low maintenance cost. The wear of brushless motor is mainly on the wear of the bearing. While from a mechanical point of view, brushless motor is almost a maintenance-free motor (its life is at least 10 times more than that of brushed motor). When necessary, just clean the dust and do some maintenance

- The motor is widely used by DIY users. It has high speed and low noise, which is suitable for engraving PCB, acrylic, drilling, etc.

Attention:

- It comes with a 10mm collet chuck by default. If you need others of different sizes, please contact us.

Spindle Specifications:

- Spindle motor: brushless DC motor (Original bearing for NSK)

- Working voltage: 48VDC (brushless driver required for motor to run)

- Power: 400W

- Speed: 12000RPM

- Torque: 0.5294 (N.m)

- Insulation resistance: >2MΩ

- Dielectric strength: 400V

- Motor diameter: 57mm/2.2" (55mm/2.2" for fixed body parts)

- Motor output shaft: thickened from the previous overall 10mm/0.4" output to 15mm/0.6" output and variable diameter 10mm/0.4"

- Length of collet chuck: collet holder 40mm/1.6" (50mm/2" including nut and sandwich)

- Chuck section diameter: 20mm/0.8"

- Overall length of motor: 190mm/7.5" (including clamping part and motor)

- Spindle net weight: 1.38KG/3LB

- Spindle radial runout: about 0.02-0.05

- Application: to engrave materials such as metal and non-metal

- With forced air cooling, the spindle can work for a long time

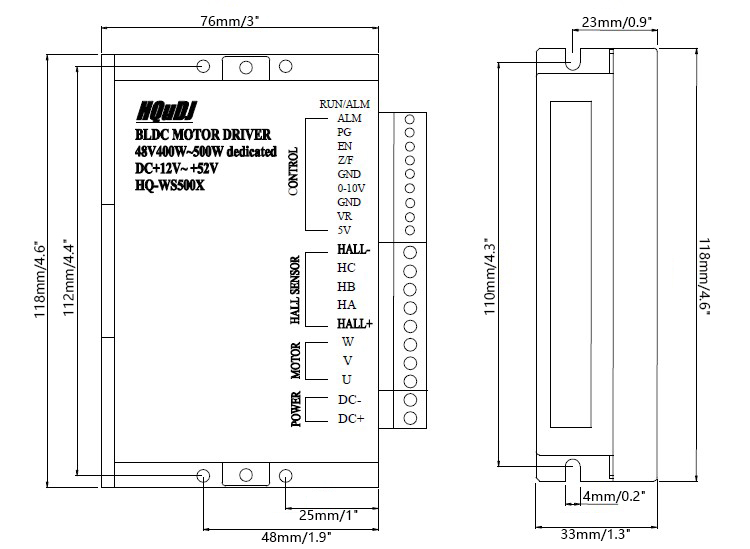

HQ-WS500X BLDC Driver (Dual-mode Version):

1. Model: HQ-WS500X (brushless dual mode) (to connect a Hall sensor or not to connect a Hall sensor)

2. Working voltage: DC12V-DC52V

3. Drive current: rated 12A; Peak 15A

4. Drive power: ≤ 500W (related to working voltage)

5. Closed-loop speed stabilization: the motor can still maintain the speed when the load is large

6. Pure hardware design, high speed and high anti-interference ability

7. External potentiometer control, and analog voltage 0-5V and 0-10V

8. Forward and reverse control, frequent start and stop function, and EN enable control

9. Over-current and short circuit protection with indication

10. With speed signal output function

Package Included:

- 1 x Spindle Motor

- 1 x Driver

Note:

- Battery is not included.

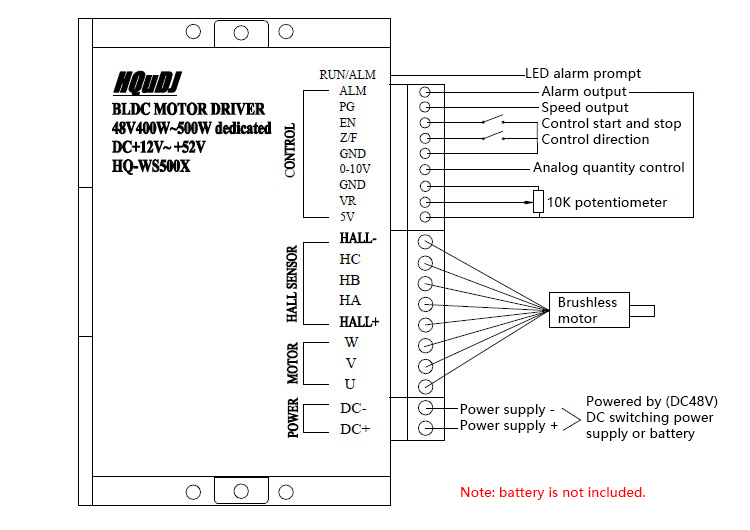

Driver's Functions:

1. DC+ and DC-: Power supply input

Support 12~52VDC input, usually using switching power supply or battery. The voltage should not exceed 55VDC to avoid damage to the driver. The rated output current of power supply should be greater than 1.5 times the output current of the driver. When using switching power supply, please pay attention to its nominal rated output current, and purchase a switching power supply that matches the motor phase current (1.2 times).

2. U, V, W: motor phase wires

Three phase lines of a brushless DC motor. Be sure to pair with Hall and wire correctly, and be sure to tighten the screws so that excessive current does not burn the driver.

3. HA, HB, and HC: Hall signal line

During operation, they must be properly paired with the phase before wiring.

4. HALL+, HALL-: Hall power cord

Hall power supply.

5. VR: speed control signal input

Support external 10K potentiometer and analog voltage speed regulation. When an external potentiometer is connected, VR corresponds to the middle pin of the potentiometer, and 5V and GND correspond to the pins on both sides of the potentiometer; When an external analog voltage (0-5V) is connected, GND is the reference ground, VR is the analog voltage input signal, and 5V is disconnected.

6. 0-10V: Analog signal input port

When an external analog voltage (0-10V) is connected, GND is the reference ground, and the 0-10V port is the analog voltage input port.

7. Z/F: Control the direction of the motor (forward/reverse)

When disconnected or connected to 5V, it is reversed; Connecting GND is for forward mode.

8. EN: Enable signal

Cannot be disconnected. When starting the motor, GND is connected, and the user can control the start or stop of the motor by controlling the on/off of the driver EN terminal and GND.

9. PG: Motor speed feedback output

Actual speed pulse signal = number of pole pairs * 3.

10. ALM: alarm and fault signal output

When the driver is abnormal, it outputs a low level at the ALM terminal.

11. LED indicator

The indicator stays on when it works normally (RUN); it will flash when there is a fault (ALM).