| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $477.86 | $468.11 | $453.48 | $433.97 | Contact US |

AD7606 16bit ADC Module 8CH Data Acquisition Module Supports 200kSPS Sampling Rate Per Channel

$27.53

AD7606 16bit ADC Module 8CH Data Acquisition Module Supports 200kSPS Sampling Rate Per Channel

$27.53

DAQ122 Data Acquisition Card DAQ Card Supports 8CH 16bit Synchronous 200K Real-time Sampling

$77.38

DAQ122 Data Acquisition Card DAQ Card Supports 8CH 16bit Synchronous 200K Real-time Sampling

$77.38

Domestic UFN3-70B413 Fork Sensor Slot Type Ultrasonic Detector with 2-Meter Cable Replacement for SICK

$222.59

Domestic UFN3-70B413 Fork Sensor Slot Type Ultrasonic Detector with 2-Meter Cable Replacement for SICK

$222.59

XCMCU XC809TF 6 Axis CNC Controller Multi-Function CNC Lathe Controller System with 7" Color LCD

Description:

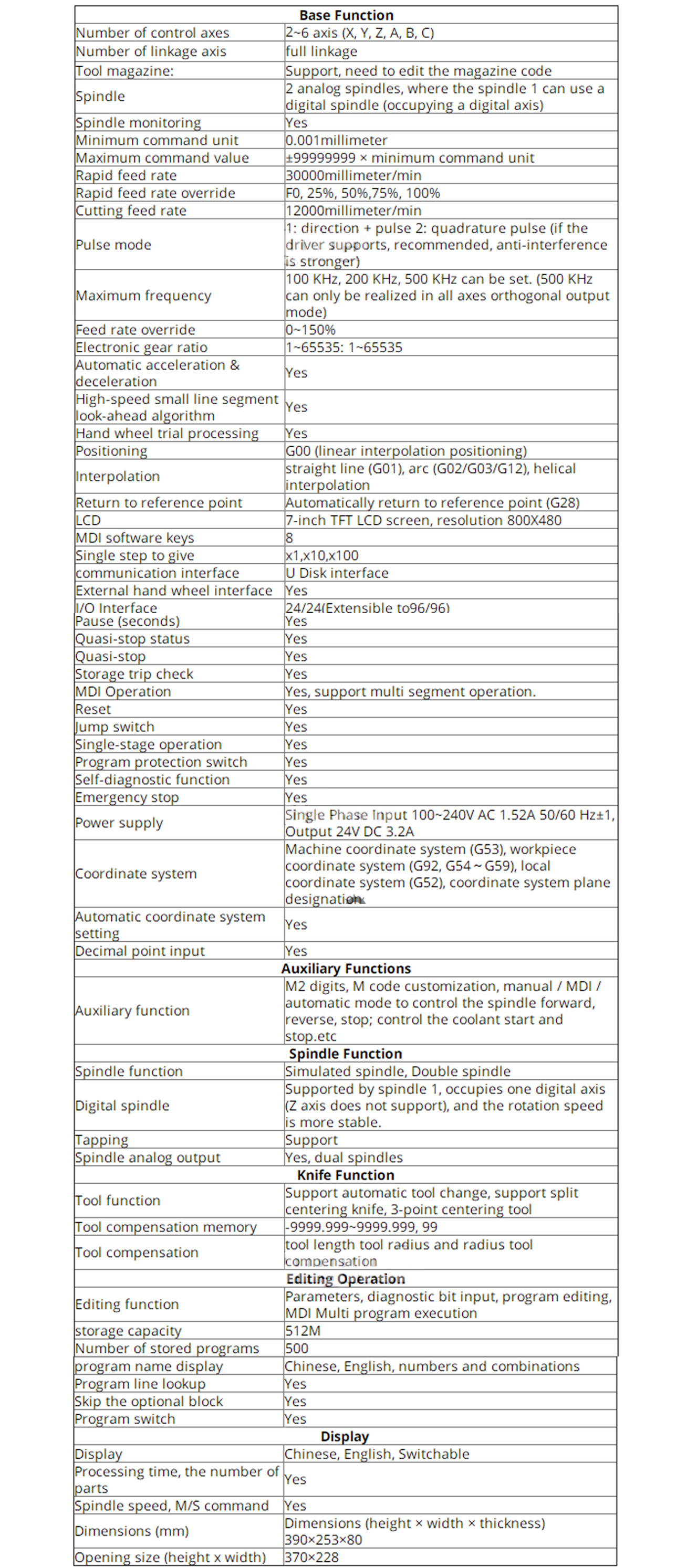

The multi-function lathe CNC system is a new generation CNC system developed by our company. It adopts 32-bit high-performance microprocessor, real-time multi-task control technology and hardware interpolation technology, fully powered, high-speed small-line algorithm. Interpolation accuracy of 0.001mm and maximum speed 30m/min.

Features of Hardware and Software:

- Based on 32-bit microprocessor, fully powered, interpolation accuracy of 0.001mm, maximum speed of 30 m/min, support direction + pulse and quadrature pulse.

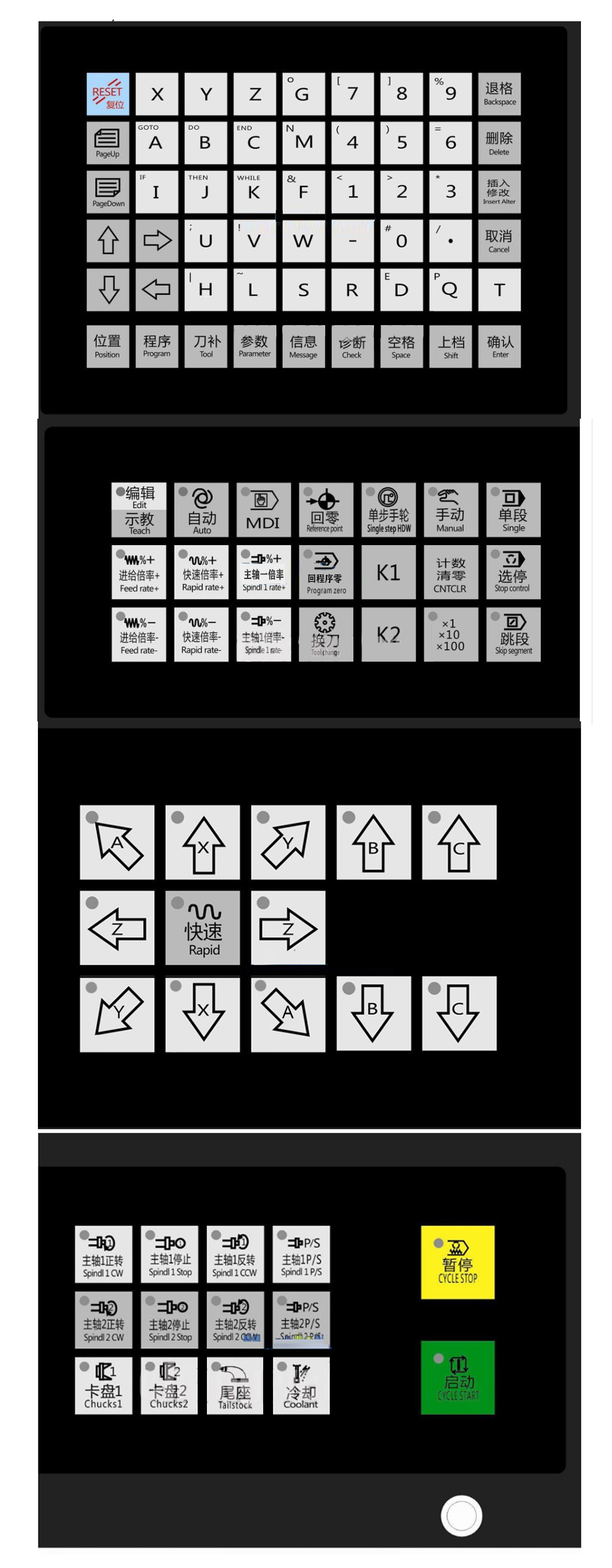

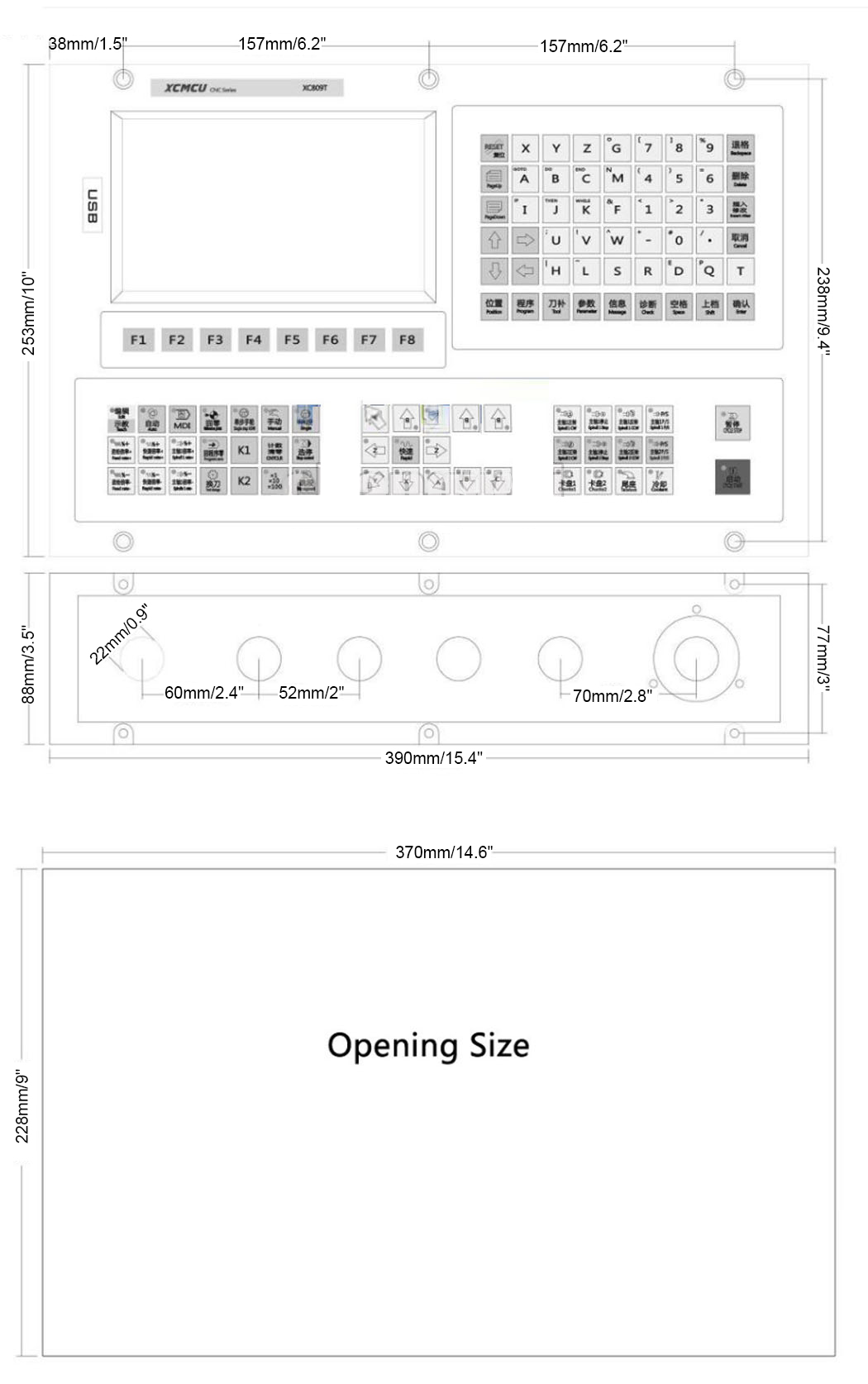

- With a 7" color LCD, 800x480 resolution, Windows style interface. Equipped with 8 soft function keys, which is simple to operate and easy to learn. Provide rich display interface, such as parameter classification, alarm logging, system diagnostics, etc., which is convenient for debugging and maintenance.

- International standard G-commands, compatible with system commands for Fanuc.

- With part program full-screen editing, and built-in 512M massive program, it can store 500 parts program.

- With USB interface, support U disk file reading and writing, and data backup.

- Input 24 (expandable to 96) points, output 24 (expandable to 96) points (custom, flexible and convenient to use.

- Chinese/English operation interface and complete help information enable more convenient operation.

- Support knife length tool compensation and radius tool compensation.

- Support handwheel evaluation processing and convenient program debugging.

- Support multi-level operation rights, convenient device management, and limited time system locking.

- Support for UG, Mastercam, PowerMill, FeatureCAM and other 3rd party G software code files.

- Support self-programming tool magazine, flexible use of a variety of tool magazines, servo towers.

- Dual spindle: support spindle 2 and spindle 1 synchronous to achieve flying cutter cutting (double servo spindle required).

- Dual spindle positioning for double-head machining.

- Simultaneous operation - one feeding program for efficient machining.

- Supports side drilling and threading of axis position interpolation 2.

Package Included:

- 1 x CNC Controller

- 1 x Expansion Panel