| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $1,994.28 | $1,953.58 | $1,892.53 | $1,811.13 | Contact US |

29PCS Dental Osseodensification Burs Kit Universal Bur Kit Surgical Tools for Dental Implant

$165.67

29PCS Dental Osseodensification Burs Kit Universal Bur Kit Surgical Tools for Dental Implant

$165.67

24PCS Dental Osseodensification Burs Kit Universal Bur Kit Surgical Tools for Dental Implant

$137.10

24PCS Dental Osseodensification Burs Kit Universal Bur Kit Surgical Tools for Dental Implant

$137.10

17PCS Dental Osseodensification Burs Kit Universal Bur Kit Surgical Tools for Dental Implant

$119.61

17PCS Dental Osseodensification Burs Kit Universal Bur Kit Surgical Tools for Dental Implant

$119.61

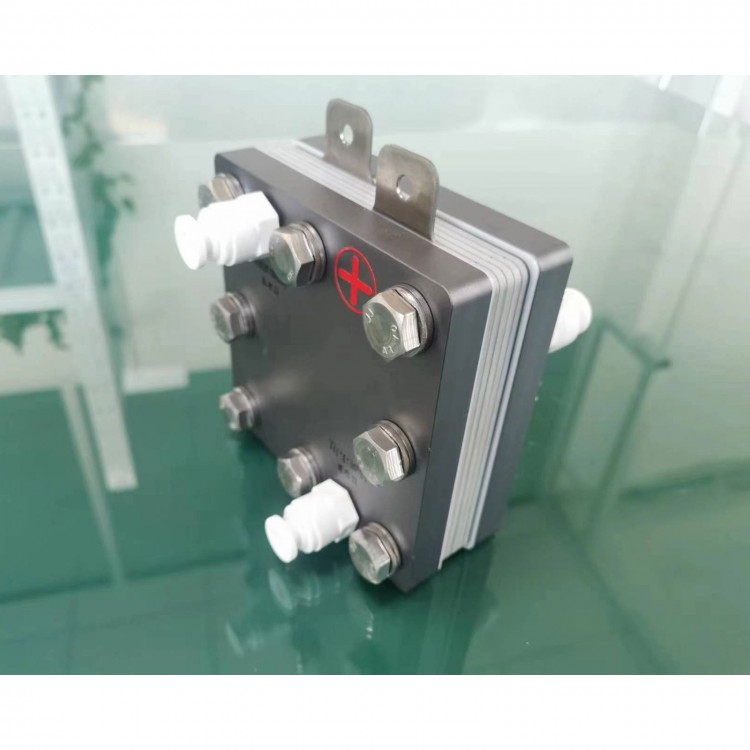

5000ML/Min PEM Electrolytic Cell Hydrogen Generator 67A 20KG Pressure-bearing Stable Electrolyzer

General Specification:

- Gas production: 5000ml/min

- Number of electrodes: 10pcs

- Thickness: 80mm

- Length x width: 124 x 124mm

Efficiency:

- Catalyst size: 70 x 70mm

- Current density: 1.34A/cm^2

Power Supply:

- Power supply type: constant current DC power supply

- Current: ≤67A

- Voltage range: ≤30V

Power:

- Initial operating voltage: ≤20V

- Initial operating power: ≤1340W

Package Included:

- 1 x Electrolytic Cell

Using Precaution:

- When designing hydrogen products, use a constant current power supply that matches the voltage and current parameters of the electrolytic cell, otherwise it may cause damage to the electrolytic cell or fail to meet performance standards.

- When designing the product, the height difference between the water tank outlet and the electrolytic cell inlet should be greater than 10cm, or a circulating water pump should be installed. There is no requirement for the height difference between the two when setting up the circulating water pump.

- The operating efficiency of the electrolytic cell is highly correlated with the working temperature, and frequent low-temperature start-up can cause certain damage to the electrolytic cell. Therefore, the issue of start-up temperature should be fully considered in product design. To solve this problem, optimization needs to be carried out in product design. Firstly, the power supply current output during start-up is controlled by the built-in program, and the output current gradually increases in steps, and finally stabilizes at the rated working current (parameters match the relevant models), during which the working voltage does not exceed the rated voltage; Secondly, an automatic instantaneous heating module or a water tank heating module should be installed between the outlet of the water tank and the inlet of the electrolytic cell to ensure that the water temperature flowing into the electrolytic cell is not lower than 25℃.

- To ensure the long-term stable operation of the electrolytic cell, it is recommended to equip the product design with an ion exchange resin filtration device, which can be installed between the water tank outlet and the electrolytic cell inlet, to ensure that the electrolytic water meets the standard requirements for use.

- If the circulating water from the oxygen outlet of the electrolytic cell is reused, it is recommended to treat it with ion exchange resin (conductivity <5uS/cm) before use, and it is recommended to add an ion exchange resin filter element.

- When designing the product, the internal space should be designed reasonably, especially with sufficient space around the electrolytic cell and appropriate flow channel design to ensure normal air flow and achieve good heat dissipation effect.

- The size of the water tank should correspond to the technical parameter table, and liquid level control and alarm devices should be installed inside the tank to ensure that the stored water level is above the minimum level.

- During the product assembly process, it is necessary to fully understand the working principle and characteristics of the electrolytic cell, prevent the joints and pipe openings of the electrolytic cell from being contaminated by other substances, and maintain a certain level of cleanliness in the assembly workshop.

- When connecting the circuit system, carefully distinguish the positive and negative poles of the electrolytic cell to prevent reverse connection, otherwise it will burn out the electrolytic cell.

- The pipeline connection should be stable and reliable, with appropriate temperature, pressure, and hydrolysis resistance to prevent aging or detachment leading to leakage; The material in contact with water must be corrosion-resistant, oxidation resistant, and high-temperature resistant. It is recommended to use teflon materials as structural components or pipelines. If metal materials must be used, it is recommended to use pure titanium materials.

- The selection of electrical components should be strict to ensure safety and reliability. Adopting a reasonable connection process to reduce unnecessary overheating. The connecting wires between the power supply and the electrolytic cell must ensure quality, and the connecting ends must be securely fastened, otherwise a large amount of heat will be generated, posing a safety hazard.

- Pure water/deionized water/secondary distilled water (conductivity <5uS/cm) must be used.

- Customers must be reminded to pay attention to the water level, and water shortage operations are strictly prohibited to prevent the electrolytic cell from burning out.