| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $268.40 | $262.92 | $254.71 | $243.75 | Contact US |

Crosbon Imported 3-Core 6mm² OFC Power Cable Soft OFC Speaker Wire (US Standard Plug, 1.5 Meters)

$37.31

Crosbon Imported 3-Core 6mm² OFC Power Cable Soft OFC Speaker Wire (US Standard Plug, 1.5 Meters)

$37.31

Geekworm 5-in-1 RAB Holder Breadboard Holder ABS Base for Raspberry Pi 5 Ar-duino UNO R3 & Mega 2560

$11.37

Geekworm 5-in-1 RAB Holder Breadboard Holder ABS Base for Raspberry Pi 5 Ar-duino UNO R3 & Mega 2560

$11.37

Portable Handheld Tesla Coil 3.0 PRO Version 0-500uS 7-level Adjustable Power Pulse Width (2600mAH meets 20000 arcs)

$51.66

Portable Handheld Tesla Coil 3.0 PRO Version 0-500uS 7-level Adjustable Power Pulse Width (2600mAH meets 20000 arcs)

$51.66

5000W Induction Heater 5KW Induction Heating Machine (Standard Version) w/ Electric Energy Meter

Description:

It is a low-power induction heating machine. It is mainly used for heating and quenching of small ferrous metal materials. It can also be used with 70mL or 150mL graphite crucibles up to 1600°C. It can easily melt metals including iron, copper, gold, silver, aluminum and others.

Features and Functions:

1. Adopt 1.6mm thick military-grade PCB, copper thickness 2OZ, featuring large current and good heat dissipation effect

2. Four 9025 cooling fans

3. Use custom oversized high-power heat sink to ensure the heat dissipation of MOSFET

4. Its output end uses 12pcs M4 copper columns in parallel. In addition to connecting the heating coil, it can also be connected to a flyback transformer and a high-frequency transformer, etc.

5. Using 10 original IRFP260 and 24 original capacitors (for BM) for parallel resonance, ensuring high power and high efficiency

6. Under the condition that the heat dissipation conditions meet the standard, this product can work continuously for a long time

7. Integrated power meter and control system make it easy to use

8. Integrated controls avoid complicated wiring

9. Heating coil is wrapped with high temperature resistant insulation material to prevent short circuit during heating

10. Add digital current overload protection switch. Once overloaded, it will automatically interrupt heating in time to protect the circuit

11. Color LCD screen displays the working parameters of the system, including voltage, current, power and temperature and capacitance of the main board. And users can switch Chinese/English with one click. The maximum working power can be set through the power meter. During work, if it exceeds the maximum working power, it will immediately enter the overload protection mode

12. Key control. It can also be connected to a foot pedal for easy control. Suitable for use in different scenarios

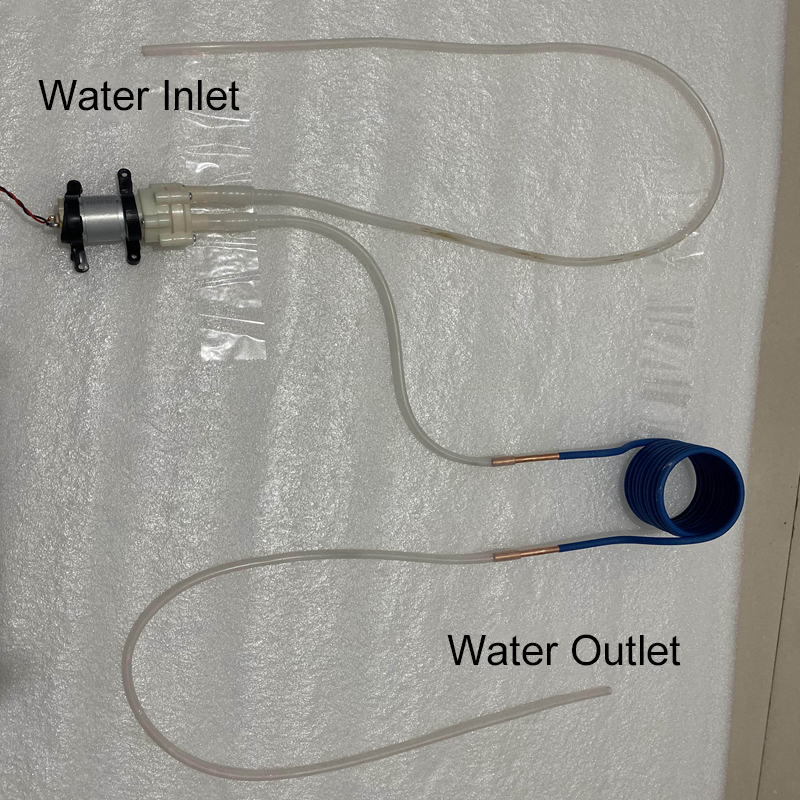

13. Water cooling system with water shortage protection

Product Parameters:

- Dimensions: 307 x 210 x 96mm/12.1 x 8.3 x 3.8" (LxWxH)

- Heating coil: 70 x 60 x 73mm/2.8 x 2.4 x 2.9" (Inner diameter x outer diameter x H)

- Working voltage: DC 48V

- Maximum DC working current: 100A

- When using the included 60mm/2.4" heating ring to heat iron, its maximum temperature is around 1000°C

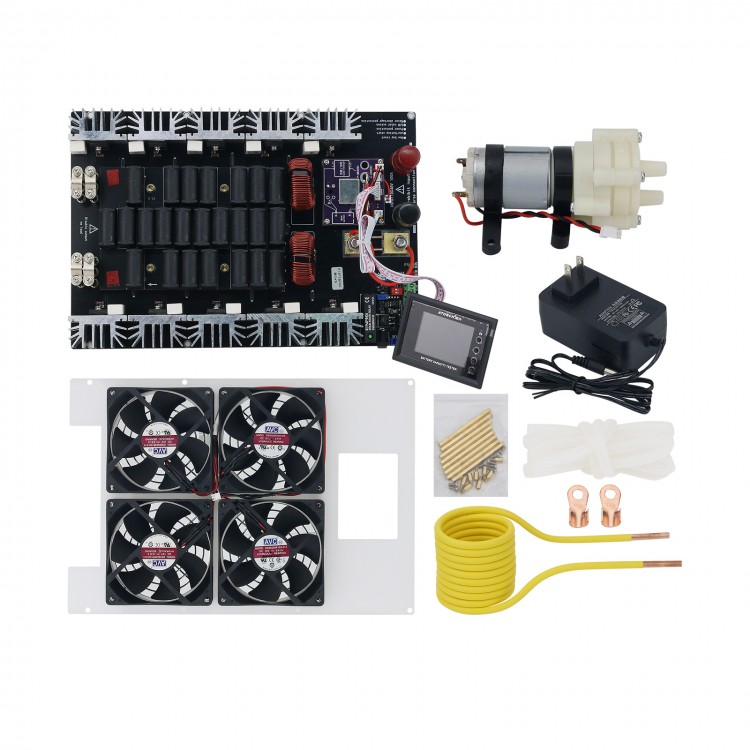

Package Included (Standard Version):

- 1 x Main Unit

- 1 x Heating Coil

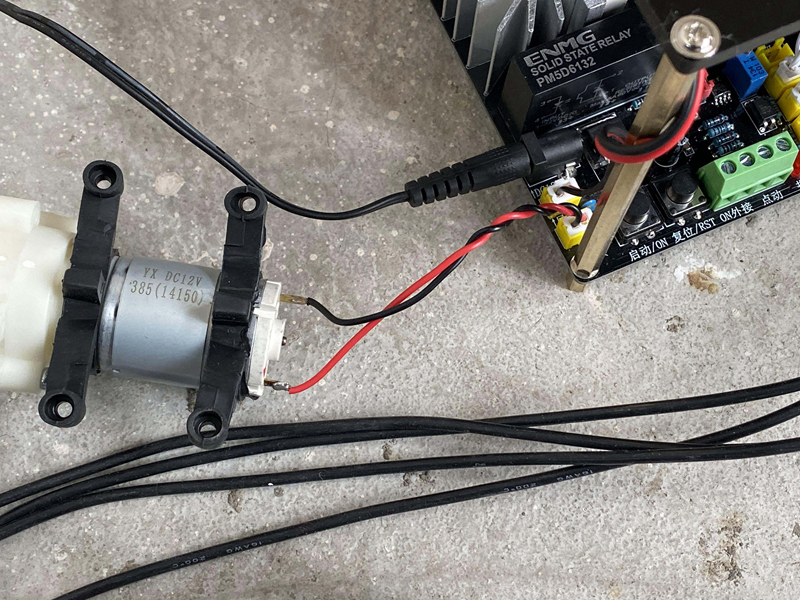

- 1 x Water Pump

- 1 x 12V 2A Power Supply

-1 x Water Pump Hose

Note:

- Other items pictured are not included, for demonstration purposes only. Thank you for your understanding!

- When used with a customized heating coil, it can forge and quench steel with a diameter of less than 20mm/0.8". (The default crucible heating coil with a diameter of 60mm/2.4". If you need to do quenching and forging, you can contact customer service to customize the heating coil). When using 20mm/0.8" inner metal iron, its maximum heating temperature is 1200℃.

Precautions:

1. The power of induction heating is very high. In addition to the heat generated by the PCB board and electronic components, the heat generated by the heating coil is also very large. In order to prevent the coil from being burned and affecting the entire system, be sure to use a water pump to cool the heating coil.

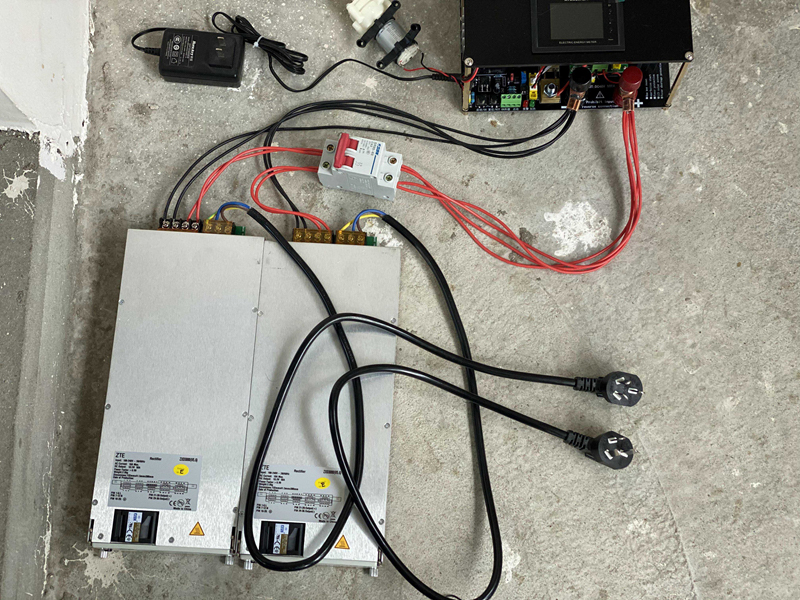

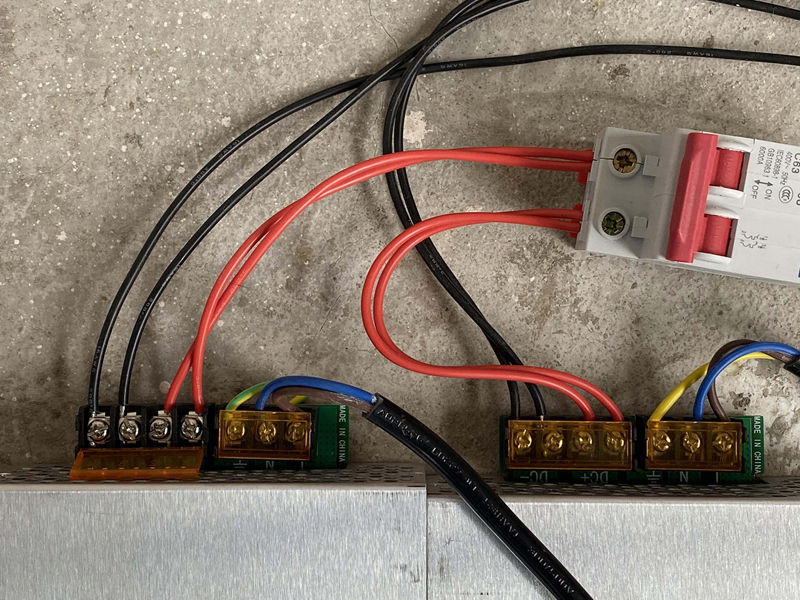

2. Care must be taken when using switching power supplies, because they generally have a slow start function, that is, the output voltage rises slowly at the beginning. If the induction heating circuit is turned on before the voltage rises to 11V, the circuit will not vibrate due to insufficient voltage, so that the MOSFETs on both sides will be turned on at the same time and the components will be burned. Therefore, it is necessary to connect the induction heating circuit after the voltage of the switching power supply is stable. You can connect an air switch between the power supply and the main board, and then push the air switch after the switching power supply is stable.

3. This circuit has very strict power requirements. It is recommended to use a 12V power supply greater than 800W, a 24V power supply greater than 2000W, a 36V power supply greater than 3000W, or a 48V power supply greater than 5000W (recommended voltage is DC 48V).

4. No matter it is used under any voltage, as long as the working current is lower than 100A, it will not burn out the circuit. Users can set the alarm current to 100A through the maximum current setting of the power meter. Heat is inevitable during high-power operation, so be sure to take cooling measures.

5. The working voltage cannot be lower than 12V.

6. When the heating machine is working, the heating coil will generate a high amount of heat. Water cooling must be used to cool the coil to avoid damage to the motherboard due to high temperature.

8. The power input port is marked with positive and negative poles. Do not connect the power supply in reverse.

9. Do not power on with no load (here, no load means that the output is not connected to any load. The situation where the device does not heat the object after the heating coil is connected is not regarded as no load), otherwise the board will emit high-frequency noise, so that the motherboard is burnt out.

10. When using a graphite crucible, a non-circulating water cooling method (the method in which cold water enters and hot water is discharged into the sewer) must be used to prevent the long-term high water temperature from affecting the service life of the equipment (this method should also be adopted during long-term high-power operation.). When the crucible is not taken out of the heating coil after heating, the 12V auxiliary power supply must not be disconnected, otherwise the water pump will stop working and the coil will be burned out by the temperature of the crucible.

Wiring:

Use Method:

1. Connect wires according to the wiring diagram above and check carefully to ensure correct wiring.

2. First plug in the 12V2A power supply to AC110V-220V, and observe whether the water pump and fan work normally.

3. If they are working normally, plug in the DC48V power supply to AC220V, wait for about a few seconds, and observe whether the voltage of the power meter on the motherboard shows about 48V.

4. If the voltage display is normal, you can press the "Heating On" button on the motherboard to start heating. Green indicator light is on and the power meter has a current display to indicate that it is heating.

5. To turn off the heating, press the "Reset" button on the motherboard. At this point, the green light will turn off and the power meter's current will be zero.

6. This heating plate has overload protection and system water shortage protection. If the pump does not work normally or there is water shortage in the pump, the system will automatically turn on the protection function and cut off the heating. At this point, the red indicator light will be on.

7. The maximum current, minimum input voltage and maximum input voltage alarm can be set.

8. If red light is on during use, the heating will stop. Please check first whether there is water flowing in the pump. If the pump works normally, check whether the equipment exceeds the maximum current. The default maximum alarm current is 100A.