| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $158.39 | $155.16 | $150.31 | $143.84 | Contact US |

G1009 10-inch Embedded HD Industrial Monitor 1024x768 Hook Mount TFT Display with BNC/VGA/AV/HDMI-compatible Ports

$109.57

G1009 10-inch Embedded HD Industrial Monitor 1024x768 Hook Mount TFT Display with BNC/VGA/AV/HDMI-compatible Ports

$109.57

G121SN01 V3 Color Active Matrix LCD Display Panel Designed for Various Industrial Applications

$88.42

G121SN01 V3 Color Active Matrix LCD Display Panel Designed for Various Industrial Applications

$88.42

RTU-307D NET-07D 8AI-8DI-8DO Data Acquisition Module IO Module (RS485+RS232) for Industrial Use

$76.89

RTU-307D NET-07D 8AI-8DI-8DO Data Acquisition Module IO Module (RS485+RS232) for Industrial Use

$76.89

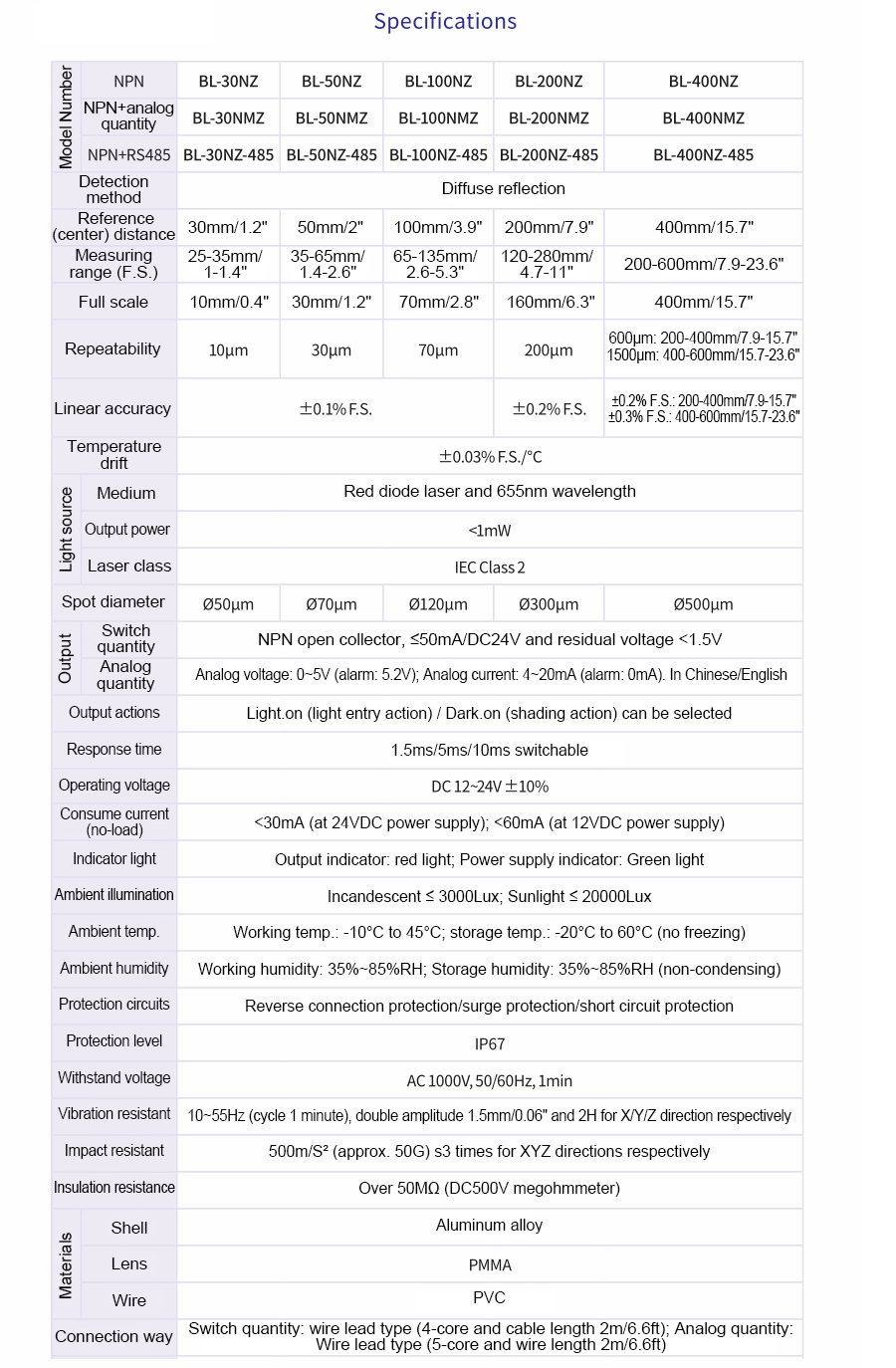

BOJKE BL-100NZ-485 Laser Displacement Sensor Supports Switch Quantity Output and RS485 Communication

Description:

Laser displacement sensor can accurately measure the position, displacement and other changes of measured objects without contact. Thus, it is mainly used to detect the displacement, thickness, vibration, distance, diameter, etc. of objects.

RS485 host computer software supports the following functions:

- Connected to a high-speed module, it can record 25 times in 1 second. Connected to a normal module, it can record 1 time per second.

- 2 groups of sensors can be connected at the same time, and the upper and lower limits of the sensors can be set. There is an alarm sound when the limit is exceeded.

- The relative distance between two groups of sensors can be set. After setting, when there is an object in the middle of the sensors, the thickness or diameter of an object can be calculated, and the upper and lower limits can be set and recorded as a document.

- It can continuously record collected data, save a CSV file corresponding to the time distance, and open it in Excel. It is also possible to manually collect data once to generate a document with a single acquisition.

Features:

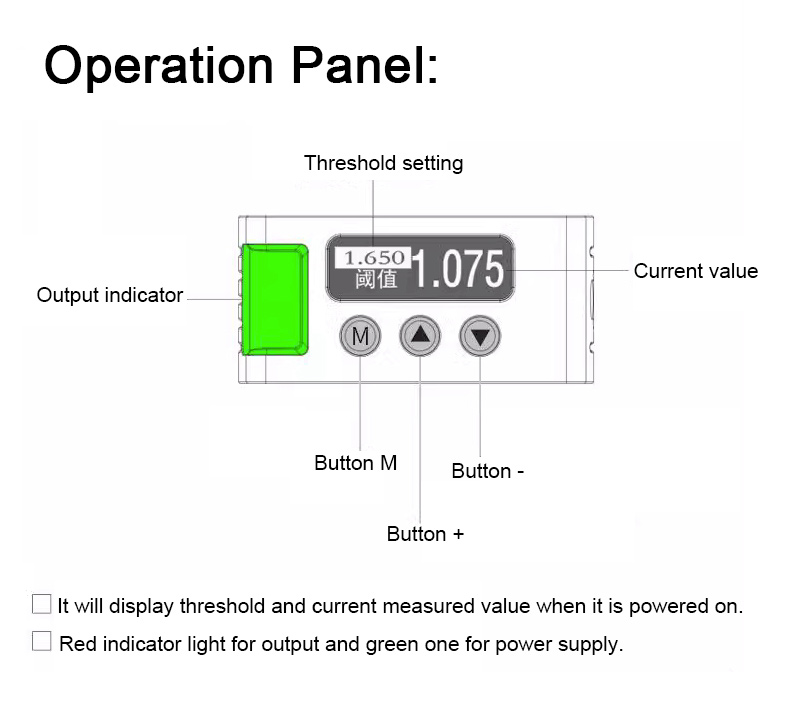

- Stable data output, easy operation and intuitive display

- Supported languages: Simplified Chinese and English

- Used to test displacement, flatness, height and thickness

- With short-circuit, over-load and reverse connection protection

- Can be connected to a computer: Equipped with a conversion module, records can be read and analyzed on the PC. The results can be shown in displays of the sensor and the PC at the same time. Users can set the upper and lower alarm values on the computer

- New design: A metallic look that stands out from the rest. It is easy to use even for green hands

- The true distance is displayed by default. No further conversion is required

- High transparency immunity filter, bidirectional visual indicator and upgraded buttons which are light and sensitive and provide a powerful feeling of bounce

Typical Application Scenarios:

- Detect the presence of miniature plain washers

- Detect the remaining amount of coils

- Detect the amount of bending of sheet materials

- Measure the amount of insertion of solenoid components

- Measure the thickness of parts

- Measure the thickness of plates

- Determine the front and back sides of cast parts

- Control the height of the inspection head of surface mount systems

- Detect the curl of substrates

External Input Control:

- M setting button for remote operation

- The current data can be zeroed

- Turn on/off laser

Menu Interfaces:

Press button M for 3 seconds to enter the menu. It will automatically return and work in standby mode if there is no operation in the menu in 20 seconds.

- Working modes: normal, high-speed and high-accuracy modes

- NO and NC: Press button M to enter the interface. Press Up or Down button to choose NO or NC mode and then press button M to confirm.

- Detection output: normal mode, one-point teaching, two-point teaching and three-point teaching.

- Difference: Default accuracy 0.07. When detecting small differences, users can minimize accuracy.

- External input: when the corresponding function is selected, the pink cable and 0V are shorted once; Zero: the current value is cleared to zero, and ± value is displayed in the range; Teaching: Can be used as pressing the "M" key once; Stop the laser: The sensor stops emitting the laser and does not work.

- Output timing: output delay, output latency, single output, output extension and no timing. Default 5-9999ms adjustable.

- Display mode: standard, reverse, and offset is to change the ±35 value to 0-70.

- Hold: The default is to turn Hold off, and you can turn Hold on/off by pressing the up/down button. That is, when the current detection value reaches the maximum or minimum, the output voltage or current can be maintained (Common application is to hold 0 or 5V after exceeding the range).

- Screen status: stay on and timed screen off.

- Reset: Pressing button M makes the display returned by default. You can switch by pressing the up/down button, press M to confirm, and the display will restore the factory settings. Press M and Down keys at the same time to control keypad locking on/off.

Package Included:

- 1 x Laser Displacement Sensor