| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $357.56 | $350.27 | $339.32 | $324.73 | Contact US |

DS300 Electric Lifter High-altitude Work Lifting Device Portable Rope Climbing Machine with 30-Meter Rope

$314.62

DS300 Electric Lifter High-altitude Work Lifting Device Portable Rope Climbing Machine with 30-Meter Rope

$314.62

DS300 Electric Lifter High-altitude Work Lifting Device Portable Rope Climbing Machine with 20-Meter Rope

$285.34

DS300 Electric Lifter High-altitude Work Lifting Device Portable Rope Climbing Machine with 20-Meter Rope

$285.34

Black G638 Portable Hidden Camera Detector Anti-eavesdrop Anti-positioning with External Lens Detector

$48.66

Black G638 Portable Hidden Camera Detector Anti-eavesdrop Anti-positioning with External Lens Detector

$48.66

DS300 Electric Lifter High-altitude Work Lifting Device Portable Rope Climbing Machine with 50-Meter Rope

Specification:

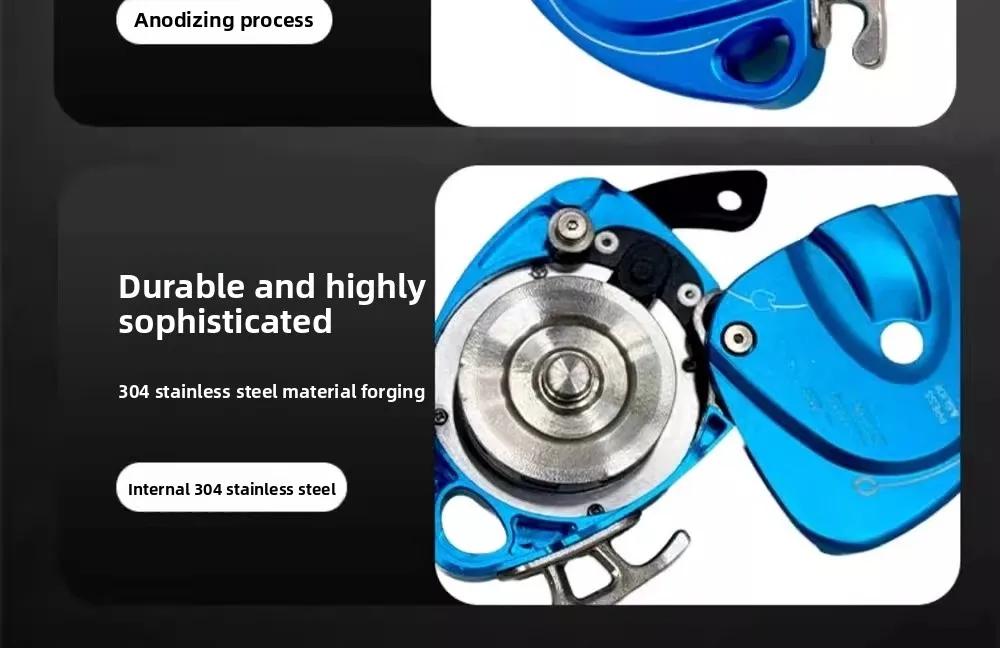

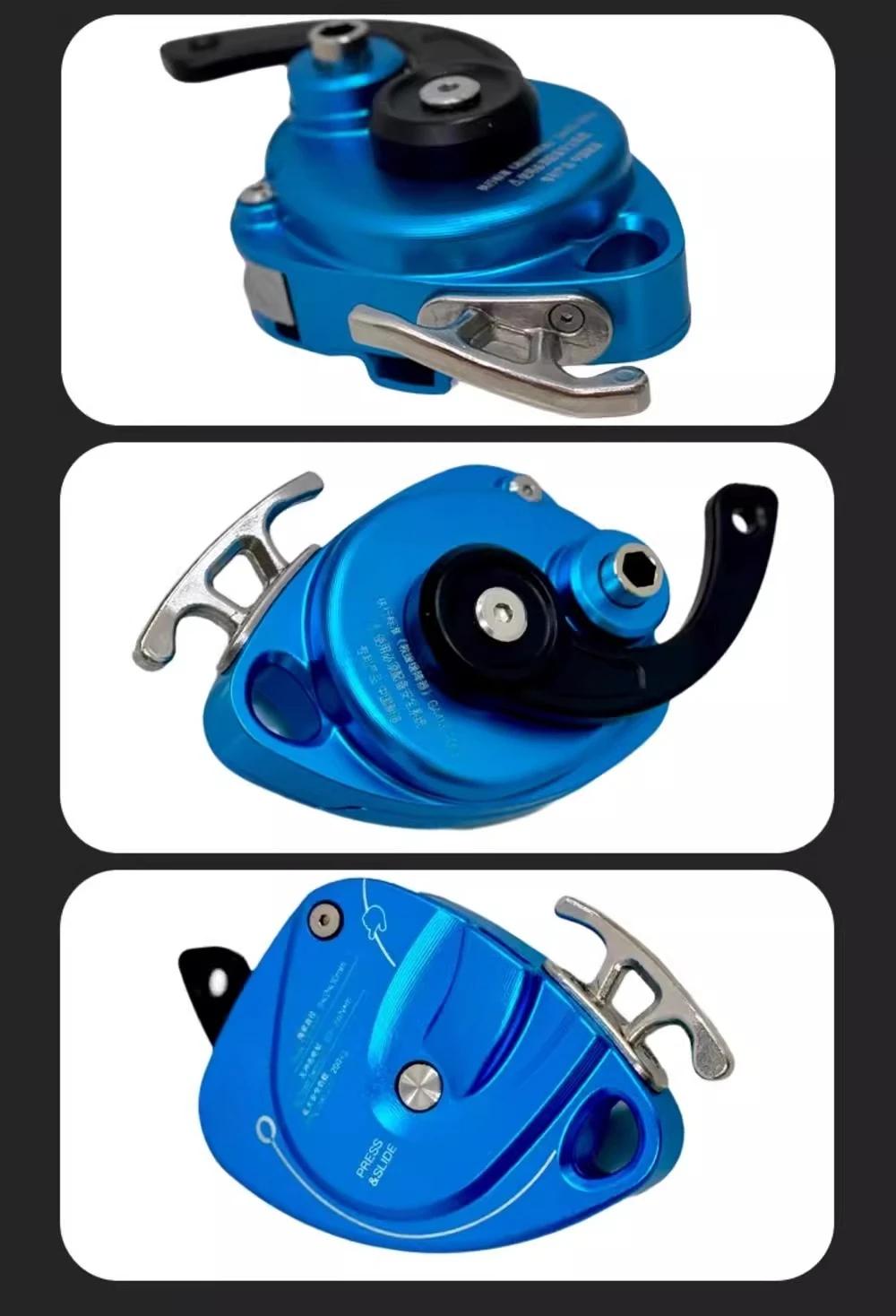

- Model: DS300

- Product net weight: 1.2kg

- Lifting load limit: 200kg

- Rope type diameter: 9 - 10.5mm

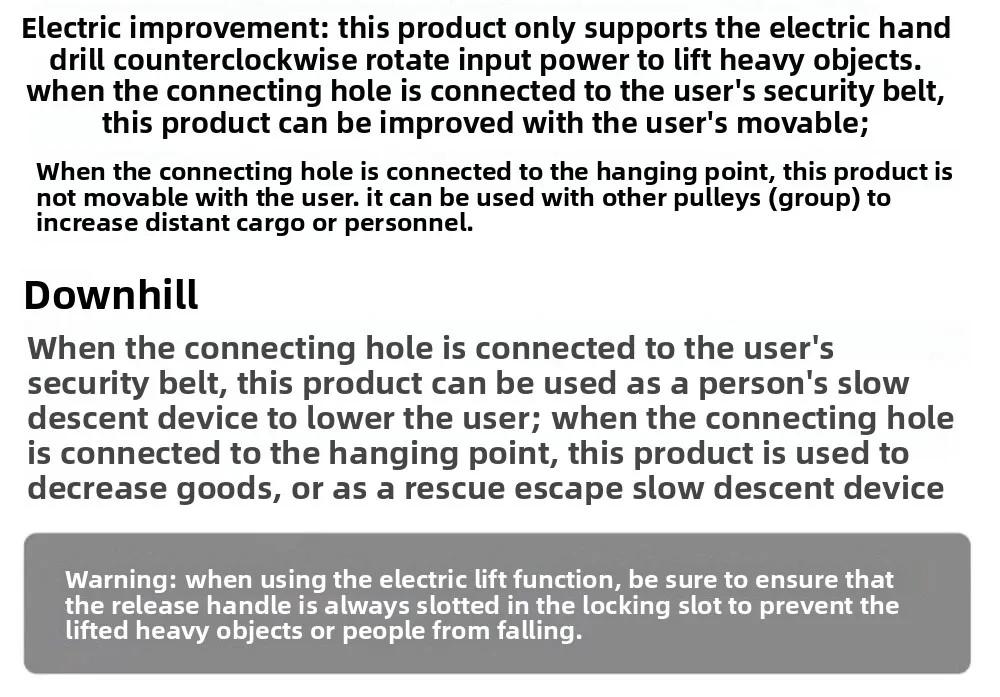

- Electric drill torque range: 50 - 150N.m and above non-impact electric drill

- Dustproof and waterproof: not dustproof and not waterproof

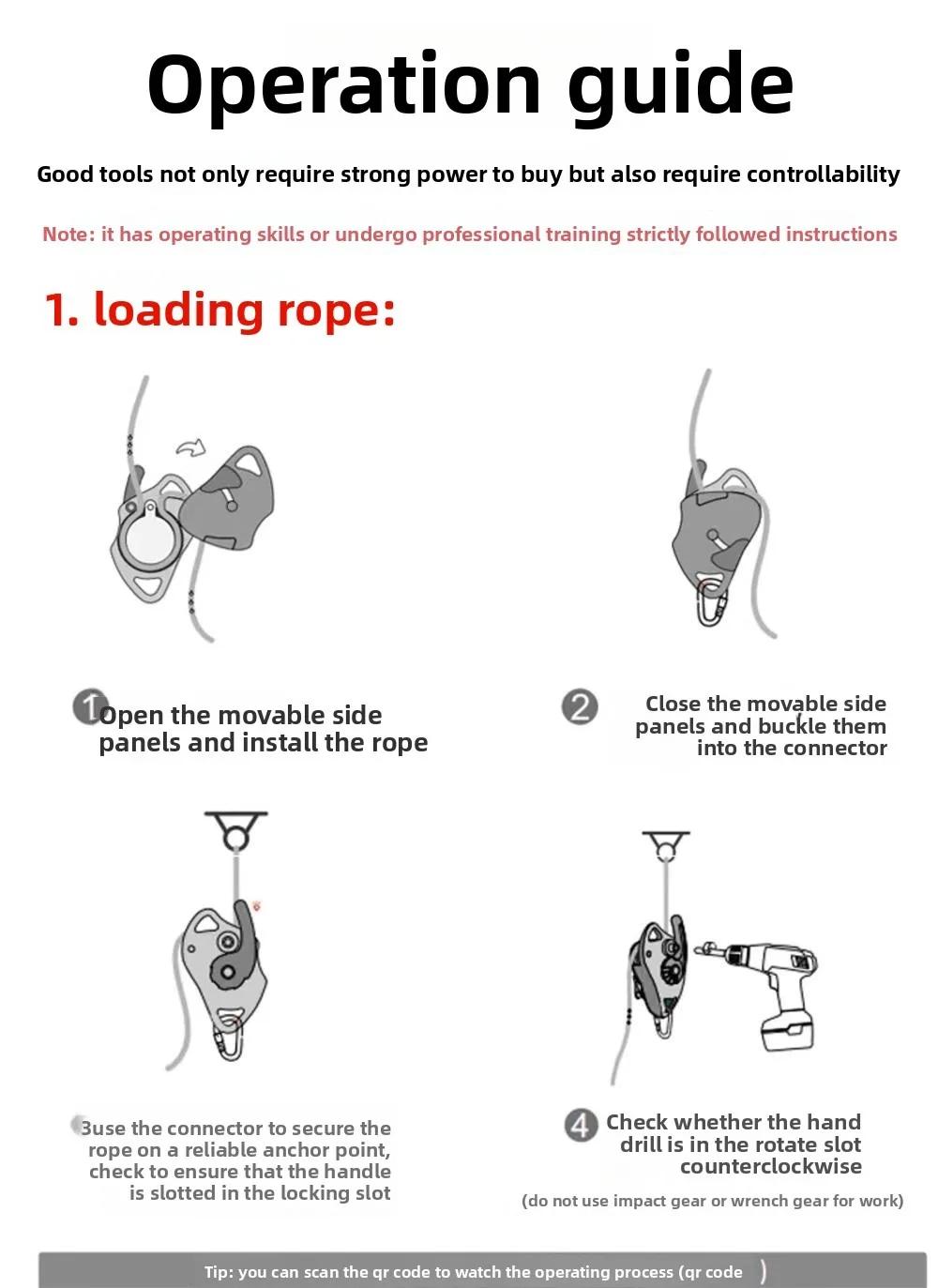

Device Safety Check:

1. Check before use:

- Before use, the product, supporting ropes and other connecting components, as well as the backup safety system, should be inspected and tested to ensure that they are functioning properly before formal use.

(1) Check if this product has any deformation, corrosion, cracks, severe wear, sharp surfaces, etc. If so, stop using it immediately and contact the manufacturer for technical support.

(2) Check the cleanliness of components such as pulleys, friction blocks, etc. If there is grease in the friction components mentioned above, it will reduce the friction force, leading to accidental falling of goods or personnel; If there are sand particles in the friction components mentioned above, it will cause rapid wear and tear.

(3) Check whether the rope is broken, the rope skin is damaged, partially thickened, partially raised, partially depressed, severely fuzzy, excessively hard, excessively soft, tangled, knotted in the middle, or dirty with mud and sand; The usage history of the rope is clear, and it has not been exposed to substances that may weaken the performance of the rope (such as oil, acid, alkali, unknown chemicals, etc.). If any of the above situations occur, the rope should be replaced with a non safety hazard rope and the above inspection should be carried out before it can be used.

(4) If the rope is damp, the load should be reduced during lifting to prevent slipping, and the rope should be slowly loosened during descent to prevent the descent speed from losing control.

(5) If the equipment experiences significant increase in gear operation noise, abnormal shaking, inability to input power, unstable or stuck lifting work, it may indicate excessive wear of the equipment's bearings and gears. It should be stopped immediately and the manufacturer should be contacted for technical support.

(6) If the power input shaft with improved function is found to be toothed or slipping, it indicates that the power input shaft is worn out. The lifting function should be stopped immediately and the manufacturer should be contacted for technical support. The malfunction of the power input shaft does not affect the use of the descent function. Tip: Other connecting components are also necessary components of system security. Please refer to the information provided by the relevant manufacturer and conduct inspections as required.

(7) Before formal use, at least one lifting and lowering test should be conducted for the lifted goods. It is recommended that the lifting height should not exceed 30cm. Pay attention to the "click" sound emitted by the ratchet during operation to see if it is clear and loud. If the sound is abnormal, the equipment may have a malfunction and should be stopped immediately. The parallel system manufacturer should obtain technical support.

2. Regular Inspection:

(1) This product has been lubricated internally. If there is a significant increase in operating noise, please add lubricating oil approved by the manufacturer. If a large amount of oil leakage is found, please contact the manufacturer for technical support.

(2) Check the handle fixing bolts described in the product structure diagram. If they protrude above the installation surface, it indicates that they have become loose. After fully unscrewing, add low-temperature anaerobic adhesive and screw it to level with or slightly below the installation surface. Allow it to solidify before use.

Package Included:

- 1 x Lifting Device

- 1 x 50M Rope