| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $118.97 | $116.54 | $112.90 | $108.05 | Contact US |

Black 3D-Printed Mini ESP32 Marauder Development Board Positioning Module with 1.44-inch Screen

$33.36

Black 3D-Printed Mini ESP32 Marauder Development Board Positioning Module with 1.44-inch Screen

$33.36

White 3D-Printed Mini ESP32 Marauder Development Board Positioning Module with 1.44-inch Screen

$33.36

White 3D-Printed Mini ESP32 Marauder Development Board Positioning Module with 1.44-inch Screen

$33.36

MPSoC XCZU19EG-F V0.3 AMR+FPGA Development Board Kit QSFP28 10Gbps Ethernet PCIE3.0 Support for Windows/Linux Systems

$1,537.98

MPSoC XCZU19EG-F V0.3 AMR+FPGA Development Board Kit QSFP28 10Gbps Ethernet PCIE3.0 Support for Windows/Linux Systems

$1,537.98

Light Spot Meter Spot Position Sensor Position Sensitive Detector PSD Quadrant Detector 2D Module

Spot Position Detector Probe: CCD Camera

Dimensions (Lens length included): 30 x 30 x 30 mm (LxWxThickness). The size of CCD sensor for SONY is 1/3 inch. Equipped with a small lens with M12 thread. The lens model is 8mm 5MP.

The wiring terminal of CCD camera is a 3-pin terminal. The three pins are for ground wire (black wire), 12V power supply (red wire), and analog video signal output (yellow wire) respectively, which are the same as the three wires of ordinary single board CCD.

Acquisition Drive Circuit Board:

Board size: 60 x 49 x 25 mm (LxWxThickness). Includes 3-pin video input and 12V CCD power supply port, RS232 communications and power supply pins (for 4 pins). In addition, there is a DC power socket welding hole on the right side, which can be soldered to a standard DC005 seat for powering the circuit board.

The update speed of spot position data output by RS232 is 25Hz.

RS232 Serial Communications & Commands:

RS232 serial communications level is TTL or 3.3V level. Users can communicate with the IO of logic chips such as MCU and DSPs according to the serial port protocol. Users can also have it communicated with a PC via a USB to RS232 (TTL level) module instead of the PC's own RS232 port or USB to RS232 (standard serial level) module or cable, because their voltages do not match with each other.

The baud rate of this RS232 serial port: 115200,

Number of digits: 8

Stop bits: 1

Check code: N

Attention: For specific commands, please see the attached text document.

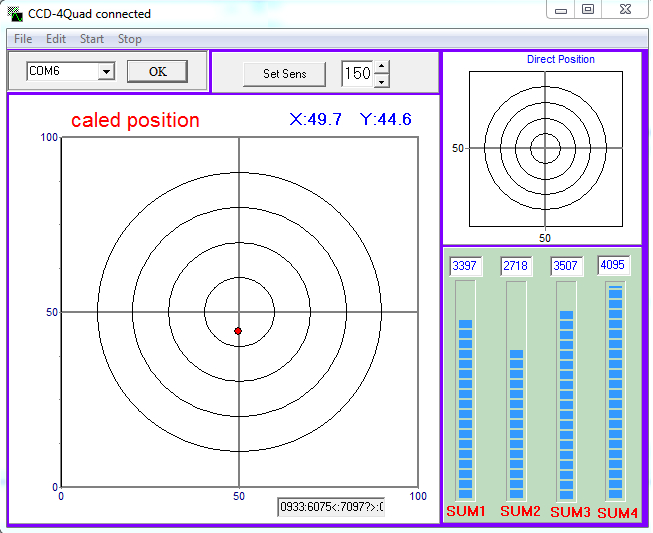

Testing Software:

As shown in the figure, please check the attached text document for the function of each part.

For BCB Source Code Description:

Please view the attached text document.

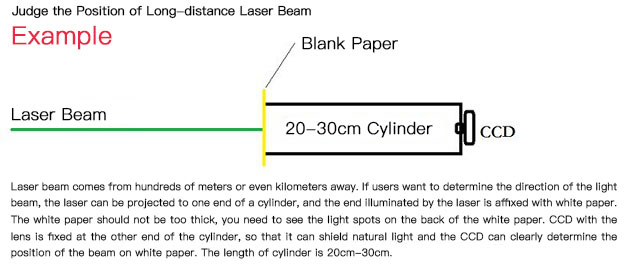

Principles & Application Introduction:

The CCD camera with a lens is an imaging device. The video signal output from the AV terminal is PAL, and the frame rate is 25 frames / second. CCD drive board also collects 25 frames / second of data for the input video signal. Each time a frame of video signal is collected, the image data is pre-processed to filter out noise, such as bright pixels and dead pixels in the CCD pixels. Then the data of the entire image is divided into four parts, which are equivalent to the four quadrants of a four-quadrant detector. Here we call it the digital quadrant. Sum the pixel data in each quadrant separately to get the intensity of the four digital quadrants. The driver board sends the strength of the four digital quadrants in the form of character strings through a serial port protocol. The receiving end, such as a host computer, converts the strengths of the four digital quadrants after receiving these strings. Finally, the formula can be used to calculate the horizontal and vertical position of the light spot on the CCD photosensitive surface.

CCD camera is generally used with M12 6mm lens. If you do not want to use the lens, you can rotate the lens directly. Because the CCD sensor chip is very sensitive, after removing the lens, an optical attenuation sheet should be attached to the light entrance or the CCD should be placed in a darkroom. In short, the influence of natural light or light should be ruled out.

After removing the lens, the light entering the CCD (generally a laser) should not be too strong to avoid burning the CCD chip. Generally, the laser that is not felt in the hand is safe for the CCD chip. The size of the light spot entering the CCD should be smaller than the size of the CCD's photosensitive surface 6 x 5mm, so the size of the spot entering the CCD is less than 4mm as much as possible, then the position measurement is accurate.

In the absence of a lens, the position accuracy is limited to the size of the CCD pixels because the light spot is directly on the CCD photosensitive surface, so the position measurement accuracy should be 10um.

When the CCD camera is equipped with a lens, its flexibility will be greatly improved. First, special attenuation of the spot intensity is not required. Because the CCD is extremely sensitive, and the driver board on the camera automatically adjusts the shutter time according to the intensity of the light, so this digital four-quadrant module can be used to locate the high-brightness sun during the day and the weak moon position at night. Secondly, special light path adjustment is not needed for the spot to be positioned. As long as the light intensity of distant spots has a more obvious contrast with the natural light of the surrounding environment, let the camera lens face the spot and rotate the camera angle. In the case of receiving data with a host computer, the light spot on the software changes regularly, which indicates that the camera has tracked this spot. Other devices can perform corresponding processing operations based on the position information output by the drive board. Thirdly, CCD camera with a lens has a good protection effect on the CCD chip. As long as the light (mainly laser) is not directly facing the lens and enters the CCD photosensitive surface, but the distant spot is imaged on the CCD surface through the lens, so it will not harm the CCD chip. When using this CCD digital four-quadrant detector to locate spot position, because the CCD judges the position of the center of gravity of the spot, the shape of the spot cannot always change, otherwise the center of gravity will change, and the position of the output spot of the driver board will jump, even the spot position has not actually changed. Attention: If strong laser projects to a certain screen in the distance, and the corresponding scattered light will also be generated around the spot, and it also has a certain intensity. The spot position detected by this position detector will not be the position of the laser spot, but the position of the center of gravity of the light intensity formed by the interaction of the laser spot and the surrounding scattered light.

Package Included:

- 1 x Set of Spot Position Detection Module with Cables

Note: Please contact us for PC software, instructions and PC source code after purchasing. Thank you!