| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $84.36 | $82.64 | $80.05 | $76.61 | Contact US |

ANNOY TOOLS 4.0 3-Axis CNC Controller Board + Offline Controller 1.8" Screen for CNC/Laser Engravers

$42.30

ANNOY TOOLS 4.0 3-Axis CNC Controller Board + Offline Controller 1.8" Screen for CNC/Laser Engravers

$42.30

ANNOY TOOLS 4.0 3-Axis USB CNC Controller Board for 2-Axis Laser Engravers or 3-Axis CNC Engraver

$23.61

ANNOY TOOLS 4.0 3-Axis USB CNC Controller Board for 2-Axis Laser Engravers or 3-Axis CNC Engraver

$23.61

F2300BT 2-Axis CNC Motion Controller Support Torch Height Control for Fangling CNC Flame Plasma Cutting Machines

$510.28

F2300BT 2-Axis CNC Motion Controller Support Torch Height Control for Fangling CNC Flame Plasma Cutting Machines

$510.28

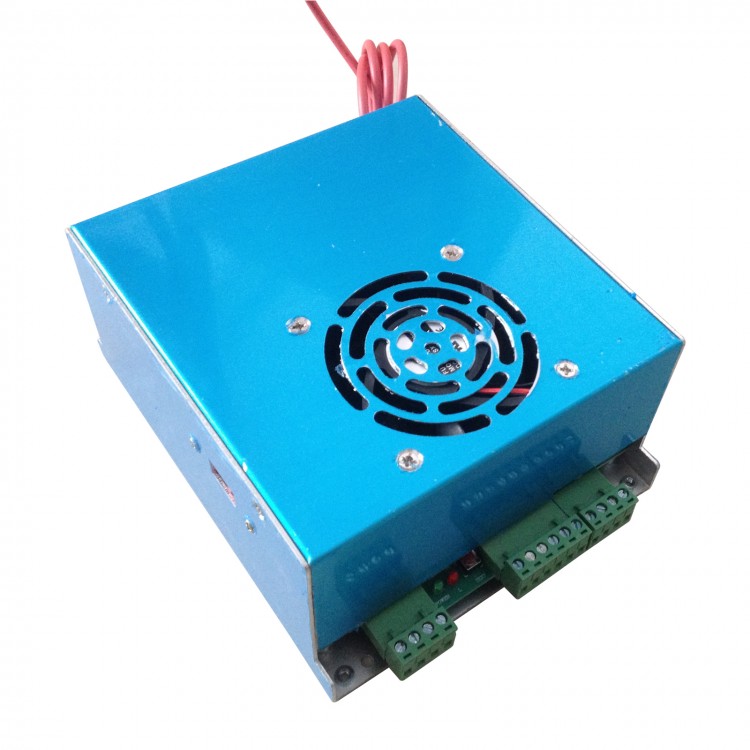

MYJG 40W CO2 Laser Power Supply CNC Engraving Cutting Machine Force Air Cooling 3A Max Input Current

Features:

- Good compatibility: it can be applicable to 30-40W Laser Tube manufactured by various factories.

- Quick response speed and effect,high performance,large cutting power,it also can prolong laser tube service life.

- Easy control: the start and stop of laser can be easily controlled by TTL level.

- The power supply has output open circuit protection.

- The power supply has TTL signal indication, water through signal indication and laser output indication.

- This power supply has the Buttonto test output laser manually.

- Application: Sculpture and cut acrylic,fabric,double color sheet and rubber etc.

Specification:

- Input: Input Voltage: AC 220V / AC 110V (Adjust with Switch); AC frequency: 47 - 440HZ; Max Input power: 250W; Max Input current: 3A

- Output:Max output voltage: DC23KV Max output current: DC20mA

- Efficiency: >/=90%(Full load)

- MTBF: >/=10000 Hours

- Response speed: ≤ 1ms (Time from the TTL Signal is given to the output current up to 90% pre-setting current)

- Withstand Voltage: Input-Output, Input-Enclosure: AC1500V 10mA 60S, Output cathode is connected with enclosure.

- Environment: Operating temperature: (-10-40)degree Celsius,Relative humidity: ≤90%

- Cooling: Force-Air Cooling(FAC)

Instructions for use:

- Connection of laser tube: The high voltage (HV +) of the laser power supply must be connected to the anode (full reflection end) of the CO2 laser tube. The current loop of the laser power supply is connected to the cathode (laser output) of the CO2 laser tube via an ammeter (or directly).

- Control signal connection: Figure 1 (or Figure 2), the control signal lines were reliable access to the laser power control terminal.

- Control signal input: As shown in Figure 3, the external computer output of the DAC signal and TTL signal input required laser power, you can control the laser tube output laser as required.

- Voltage selection: Laser power requirements for the input 220VAC / 50Hz, for 110VAC should be special order.The laser power supply has a set of protection switches that can be connected in series to protect the water, to protect it when opening the enclosure.

Notice:

- The laser tube must work with water cooling.

- High-voltage output must not open! (The positive and negative terminals of the high voltage output and the positive and negative terminals of the laser must be connected correctly.

- Power has been added to the internal discharge resistor, the power supply after the power failure in general within two seconds to release the residual pressure. But for safety reasons, should still be noted that the attention of electric shock! (High-voltage output must be to ensure that both ends of the high-voltage 40KV suspension of the insulation safety requirements.)

- The laser power supply must use a three-prong outlet with a grounded terminal. Chassis must be strictly grounded! To avoid electric shock.

Paqckage List:

- 1 X MYJG 40W Co2 Laser Power Supply Equipment