OIDelec OID-CAN-1000W FOC BLDC Motor Driver BLDC Motor Controller Servo Motor Driver for CAN Signal

Features:- High-performance FOC BLDC motor driver: Fast dynamic response, low torque fluctuations, high efficiency and ultra-quiet operation

- It is suitable for more than 90% of motor models on the market. The driver is suitable for DC sensored/sensorless brushless motors and in-wheel motors

- FOC driver enables precise control

- Supported speed regulation modes: duty cycle speed regulation, torque control, speed closed-loop control and position closed-loop control (angle control)

- Support constant speed, constant torque (constant current) and constant power output

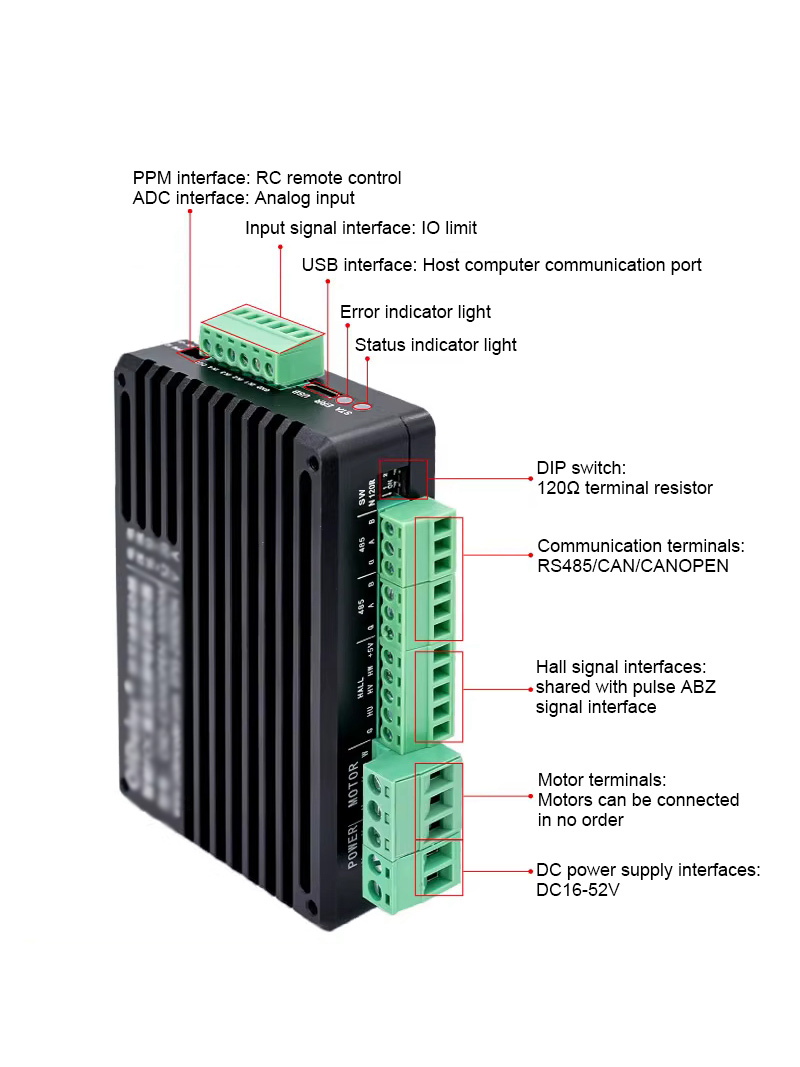

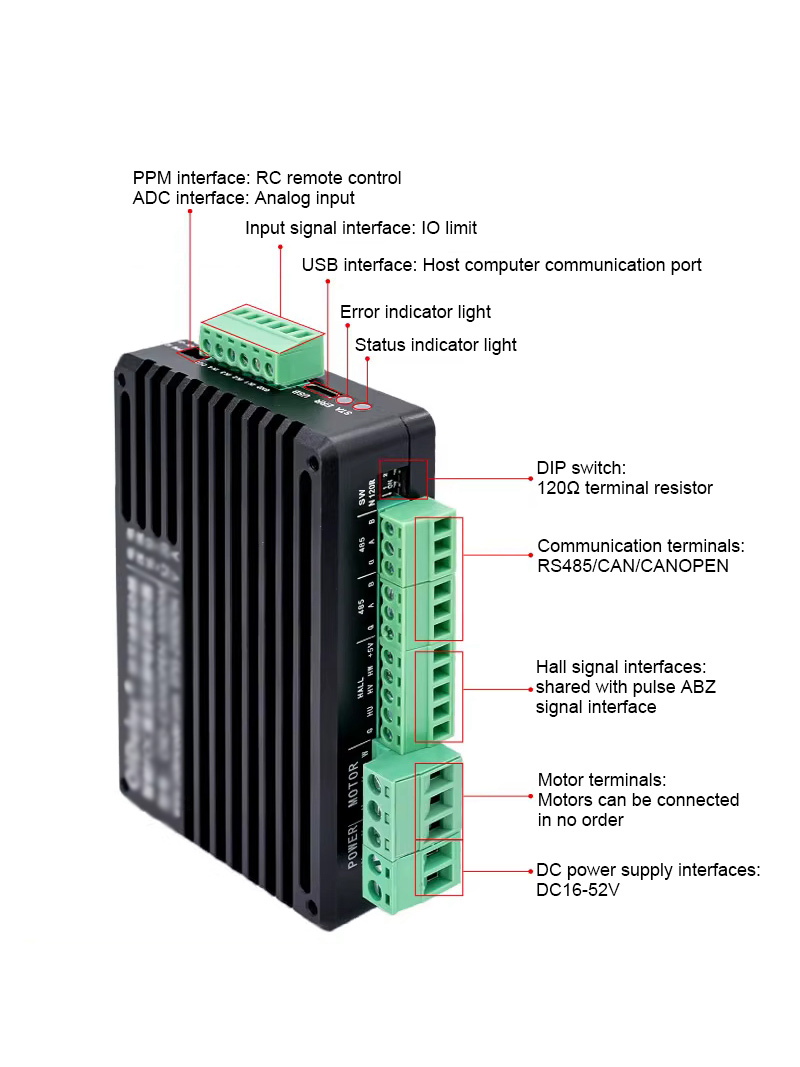

- Supported input signals include potentiometer, analog signal, PPM and RS485/CAN/CANOPEN

- Potentiometer, analog signal and PPM can be used to learn the mapping range through a host computer. It can adapt to signals with different resistance values and different times (duty cycles)

- RS485/CAN/CANOPEN communication isolation; support RS485/CAN/CANOPEN multi-site communication, making it convenient for the communication and control of multiple controllers (such as PLC)

- Motor current PID parameter is automatically set, and speed PID and position PID can be configured on the host computer

- The maximum start/load current and braking current can be configured separately

- Support internal temperature monitoring of the driver and over-temperature protection temperature can be configured

- Support driver power supply voltage monitoring and over-voltage/under-voltage shutdown monitoring value can be configured

- Support multiplication output, high torque output when starting or with a large load

- In the state of constant power or constant torque, the motor can stall for output for a long time

- It can intelligently learn new motors and can be quickly replaced to adapt to new motors

- Real-time display of information, including motor speed, position and temperature

- Upper computer is equipped with a limit switch. Flexible configuration according to application scenarios

- Support motor speed measurement, motor stall detection/stall limit stop

- It can adapt to complex field environments, with ESD protection for all interfaces

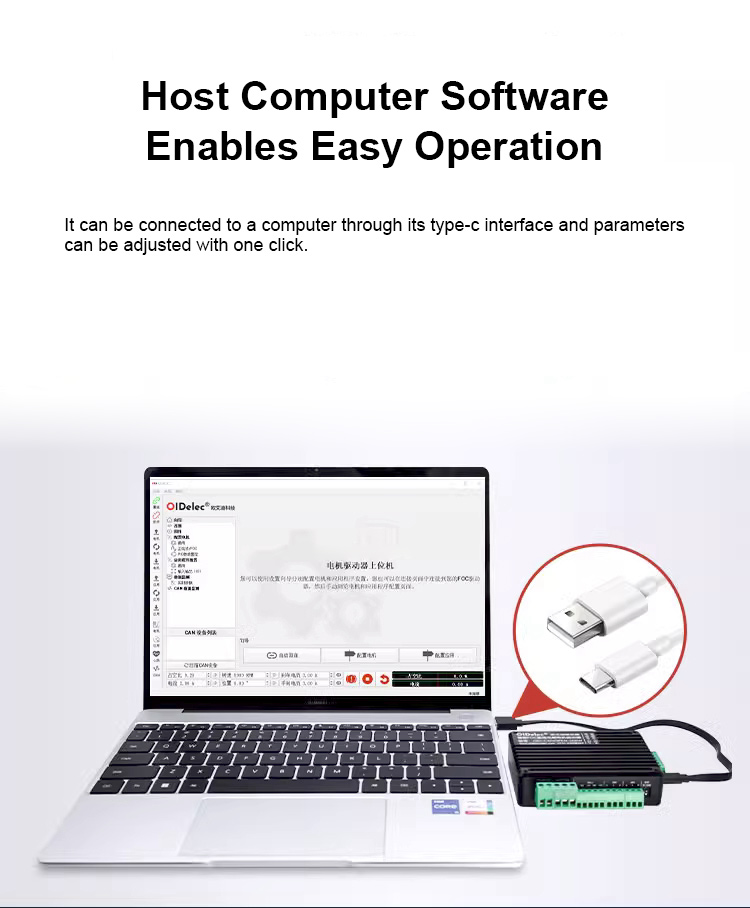

- Multifunction host computer software makes the operation simple and convenient: Motor learning, serial port parameters, real-time display of motor operating parameters, PPM input matching, set motor parameters, input and output limit IO actions, read, modify and save configurations, acceleration and deceleration curve setting, set closed-loop parameters, motor setting control, firmware upgrades and analog input matching

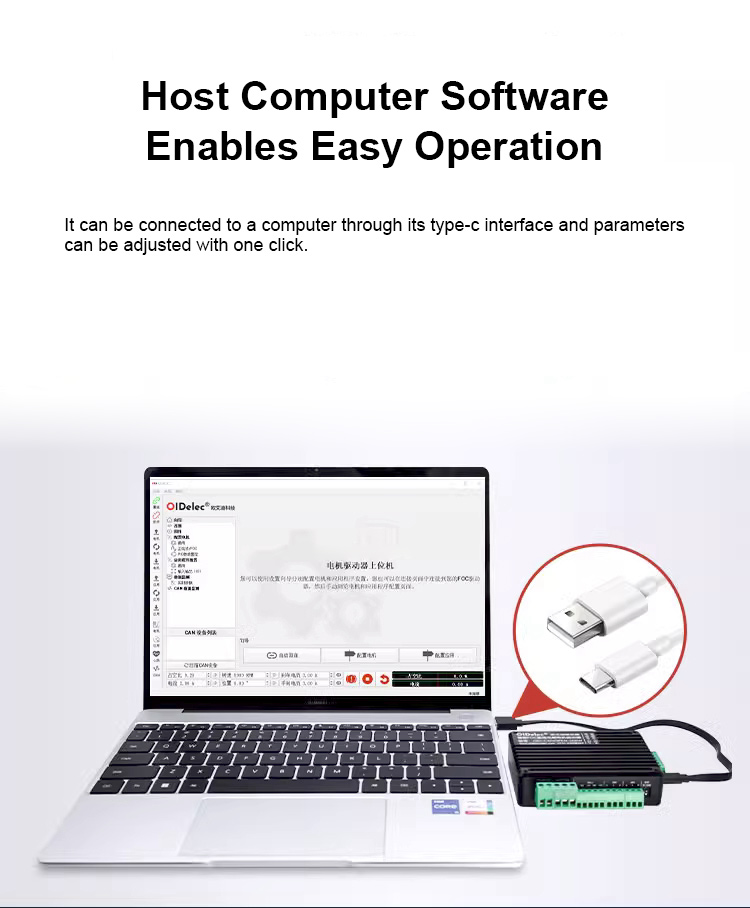

- It can be connected to a computer through its type-c interface and parameters can be adjusted with one click

- Built-in segmentation algorithms make it smoother to run: PWM frequency of 25kHz, more silent when the motor speed is regulated without PWM. With ARM Cortex-M4 168MHz processor, the operation is not limited. High-power MOSFETs enable more powerful and more stable operation. High-speed USB communication to obtain driver board information in real time. High-precision integrated sampling resistors are more sensitive to acquisition phase resistance. Optocoupler isolates input and output to cope with various complex environments

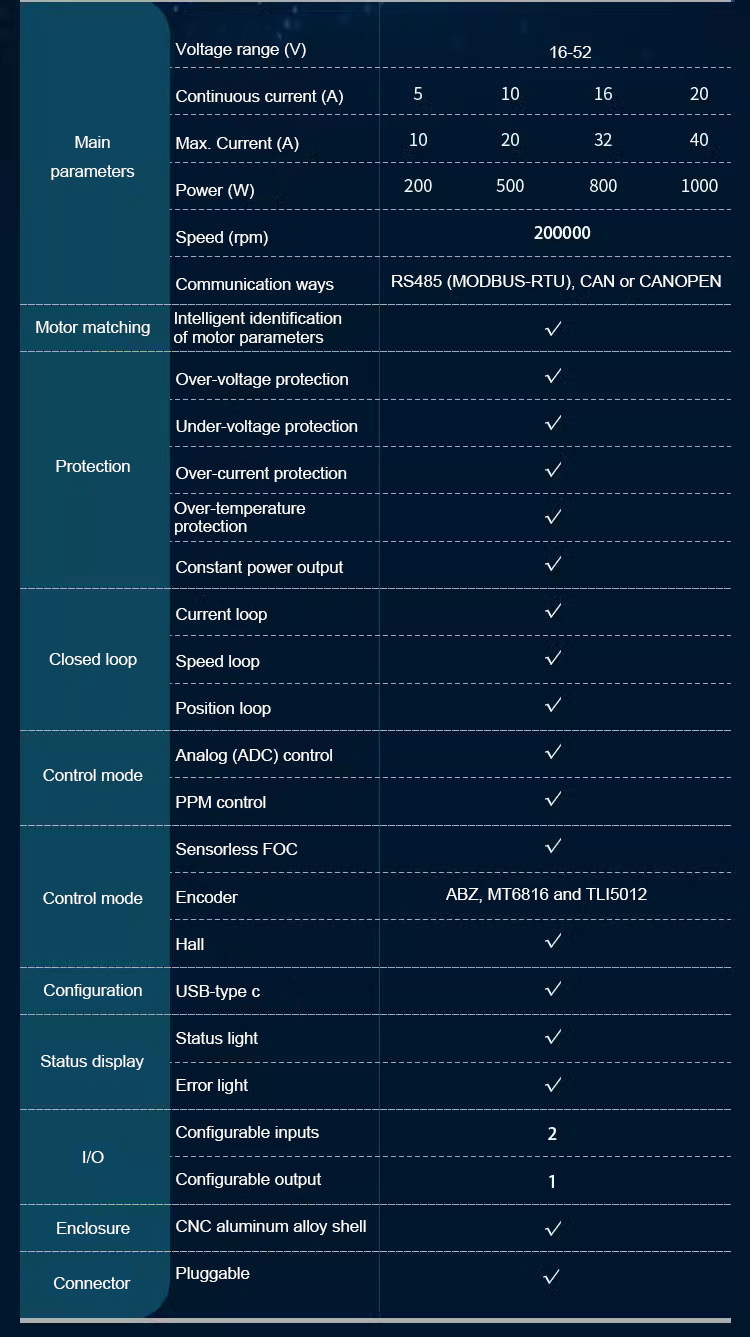

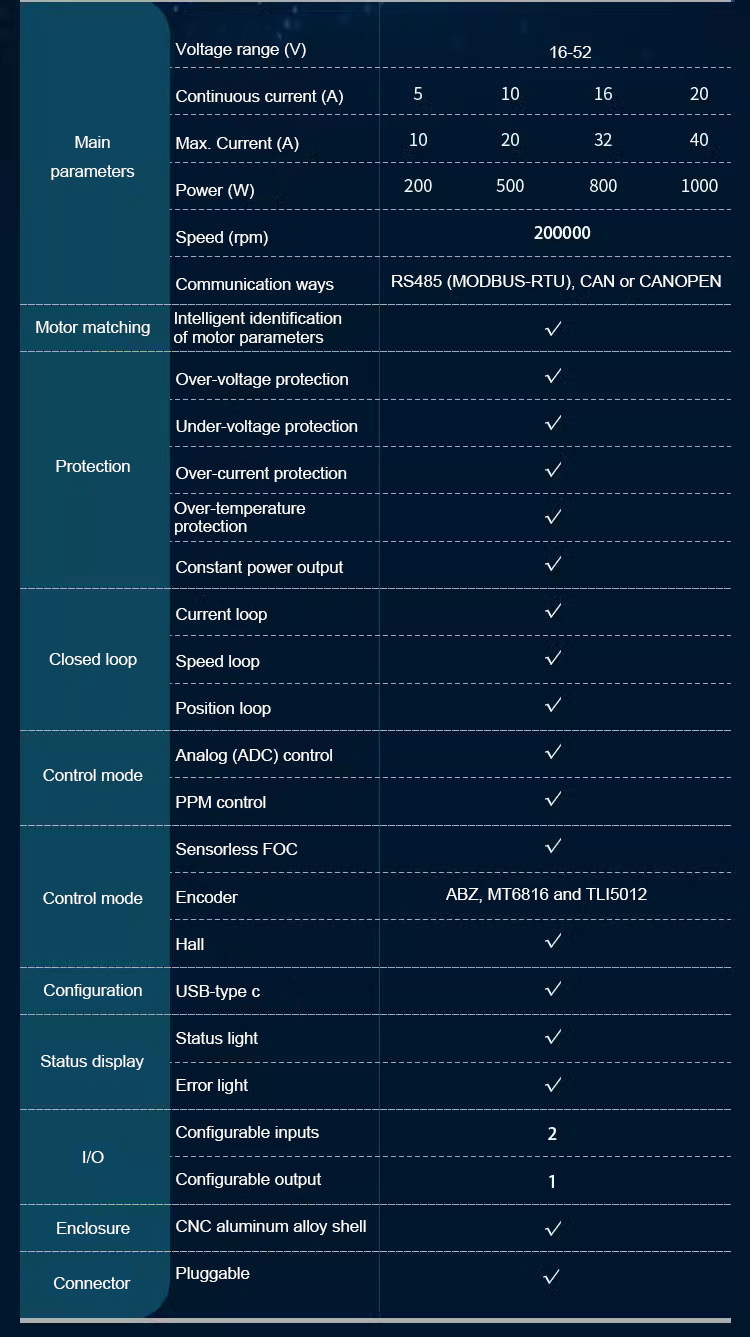

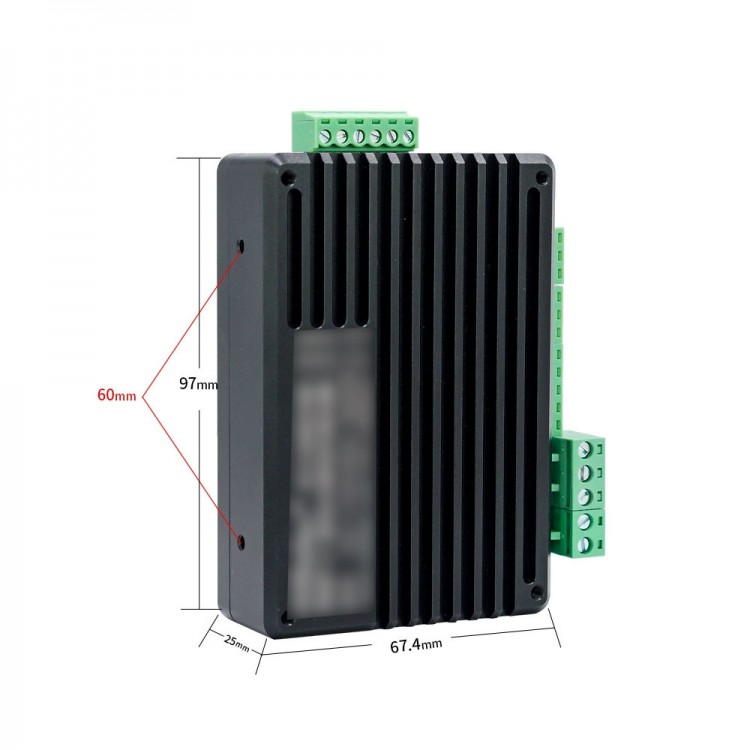

Specifications:- Communication terminal: CAN

- Power: 1000W

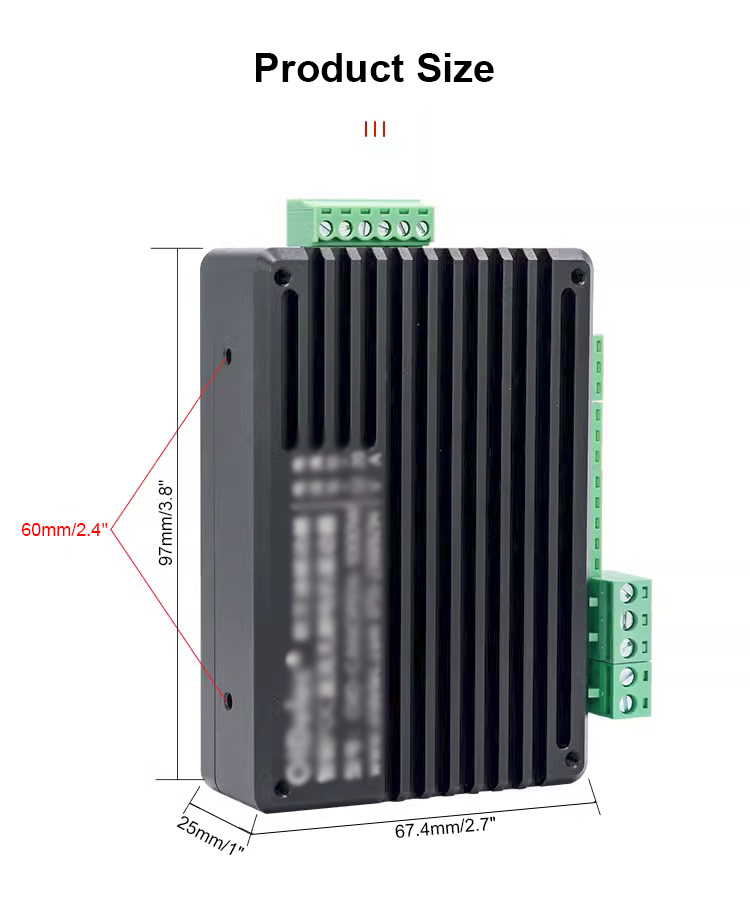

- N.W.: 0.537kg/1.2lb

- G.W.: 0.8kg/1.8lb

Package Included:- 1 x BLDC Motor Driver

Note:

- 1200W, 1500W and 1800W are optional and please contact us for detailed prices.Attention:1. The product is powered by DC power supply. Make sure that the positive and negative terminals of the power supply are properly wired before powering it on.

2. Do not plug and unplug cables with electricity. It is not allowed to short the cables when it is powered on, otherwise it will cause damage to the product.

3. Because the driver is not sealed, please not mix screws, metal chips and other conductive foreign substances or flammable foreign substances inside. Please pay attention to moisture and dust protection when storing and using.

4. The driver is a power device, and try to keep the working environment heat dissipated and ventilated.

G1009 10-inch Embedded HD Industrial Monitor 1024x768 Hook Mount TFT Display with BNC/VGA/AV/HDMI-compatible Ports

$109.57

G1009 10-inch Embedded HD Industrial Monitor 1024x768 Hook Mount TFT Display with BNC/VGA/AV/HDMI-compatible Ports

$109.57

G121SN01 V3 Color Active Matrix LCD Display Panel Designed for Various Industrial Applications

$88.42

G121SN01 V3 Color Active Matrix LCD Display Panel Designed for Various Industrial Applications

$88.42

RTU-307D NET-07D 8AI-8DI-8DO Data Acquisition Module IO Module (RS485+RS232) for Industrial Use

$76.89

RTU-307D NET-07D 8AI-8DI-8DO Data Acquisition Module IO Module (RS485+RS232) for Industrial Use

$76.89