| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $20.33 | $19.91 | $19.29 | $18.46 | Contact US |

Gravity Waves BLACK DOMAIN Tube Amp Attenuator Dummy Load Box for Tube Amplifiers ≤200W

$143.04

Gravity Waves BLACK DOMAIN Tube Amp Attenuator Dummy Load Box for Tube Amplifiers ≤200W

$143.04

Gravity Waves Tube Amp Bunker Tube Guitar Amp Attenuator Load Box and Cab Sim Combo (Silver)

$414.91

Gravity Waves Tube Amp Bunker Tube Guitar Amp Attenuator Load Box and Cab Sim Combo (Silver)

$414.91

20W Gravity Waves Bluespace White All-Tube Guitar Amplifier Guitar Tube Amp Combo with Stand & Pedal

$1,490.66

20W Gravity Waves Bluespace White All-Tube Guitar Amplifier Guitar Tube Amp Combo with Stand & Pedal

$1,490.66

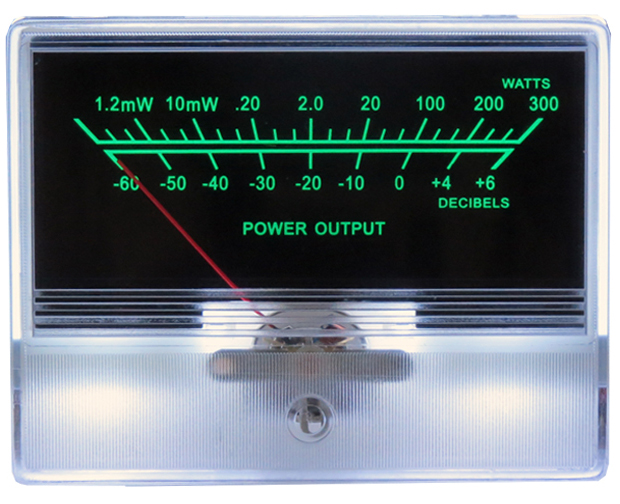

TN-90 High-Precision VU Meter DB Sound Level Meter Backlight For Power Amplifier Tube Amplifier

Description:

It is equipped with a backlight plate, and white LED light source with homogenizing plate to evenly diffuse the light. The hollow dial has a pure black background. Green scale marks and characters are very beautiful after power on.

Appearance & structure:

1. Movable part, moving coil type

2. Appearance: check details below

3. Degree board: check details below

4. Pointer material: zinc-nickel alloy. Pointer color: orange. Pointer swing direction: from left to right. Pointer length: 44+1mm from the central axis to the needle end. Pointer width: 0.45±0.05mm

5. Electric setting direction: vertical

Electrical performance:

6. Standard test conditions: 20℃, humidity 70%. Test can also be carried out under normal temperature and humidity if there is no difference in the test results

7. Current sensitivity: The pointer is at the zero scale to the maximum scale (full scale position), the sensitivity is 960uA+8%

8. Internal impedance: 650Ω±10%

9. Insulation resistance: 500V DC plus 50M ohm or more for the outer box of the meter and the electrical circuit. The insulation resistance of the meter case and the electrical circuit is tested with a 500V DC voltage.

10. Zero position: The meter uses the standard posture. The front end of the pointer and the center of the zero scale are used as the reference. The overlap tolerance of the pointer and the zero scale is ±1mm.

11. Balance: The allowable error range of the meter is ±1mm when the standard position is tilted forward and backward by 90 degrees

12. Pointer sticking: instantaneously add the full-scale current three times the overcurrent, and slowly decrease to the reading of 1/2 of the current sensitivity, then the pointer will return to within 1/3 of the scale

13. Friction: When the electric current is applied to the electric meter, the error range of the indication point is ±1mm when it slowly increases or decreases to a certain value

14. Braking: Instantly add 2/3 of the current value of the scale plate, within one second from the beginning to the pointer indicating position

Special tests:

15. Overload test: Input ten times the full scale current every five seconds. This action is repeated nine times. Each time is 0.5 seconds. After this test, items 7-14 remain normal

16. Vibration test: After packaging, the meter will vibrate up and down 4mm 1,000 times per minute on the vibrating plate, 10 minutes in each direction. After this test, 7-14 items remain normal

17. Impact test: After the meter is packaged, it is dropped from a height of 30 cm on a 3cm thick wooden board, tested in X.Y.Z. three directions, and the 7-14 items remain normal after this test.

18. Reliability test: After 100,000 calibration point current input, the current sensitivity limit is still within the standard

19. Environmental impact test: 50℃, humidity 85%, lasting 100 hours. After this test, 7-14 items remain normal

20. Terminal pull test: The terminal must withstand a pull of 1 kg for 60 seconds without being affected

Others:

21. Operating temperature limit: -10℃ to+60℃, RH 35% to 85%

22. Storage temperature limit: -20℃ to +60℃, RH 35% to 85% (Not place the meter under direct sunlight, and store the meter in a packing box to prevent objects from entering the inside of the meter)

23. Soldering conditions: Put the terminal about 3 mm into tin plate at 230℃ for 3.5 seconds. After this test, items 7-14 remain normal. Soldering temperature: Hold solder gun at 350℃, and touch the terminal for 3.5 seconds , the front end of the terminal is about 3mm in contact with the solder gun. After this test, 7-14 items remain normal

24. Anti-static: Use a dry nylon cloth to test three times in the same direction on the surface of the transparent cover. The difference of the pointer on the mark is less than 1/3 of the length of the scale, and it returns to the zero position after three seconds

25. Bulb specifications: two white LEDs 2.8-3.0V backlight board (voltage can be changed to 12V for free. If necessary, please contact us)

Package Included:

- 1 x Set of VU Meter

Note:

- Other items pictured are not included, for demonstration purposes only. Thank you for your understanding!

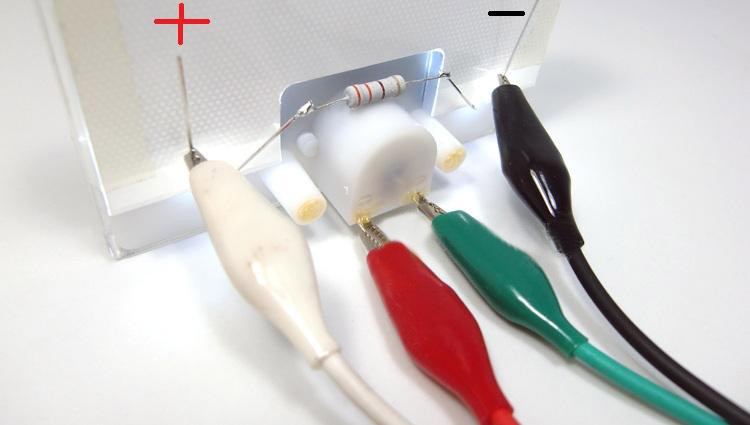

After connecting voltage divider resistor in series, the backlight voltage is changed to 12V, as shown in the figure: