| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $211.71 | $207.39 | $200.91 | $192.27 | Contact US |

ANNOY TOOLS 3-Axis CNC Controller Board GRBL 1.1f with USB Cable for Offline Controller 500W Spindle

$34.79

ANNOY TOOLS 3-Axis CNC Controller Board GRBL 1.1f with USB Cable for Offline Controller 500W Spindle

$34.79

5pcs Top Suction Plates Rubber Suction Pad (125mmx75mmx17mm with Large Hole) for Vacuum Blocks

$39.60

5pcs Top Suction Plates Rubber Suction Pad (125mmx75mmx17mm with Large Hole) for Vacuum Blocks

$39.60

5pcs Top Suction Plates Rubber Suction Pad (125mmx75mmx17mm with Small Hole) for Vacuum Blocks

$39.60

5pcs Top Suction Plates Rubber Suction Pad (125mmx75mmx17mm with Small Hole) for Vacuum Blocks

$39.60

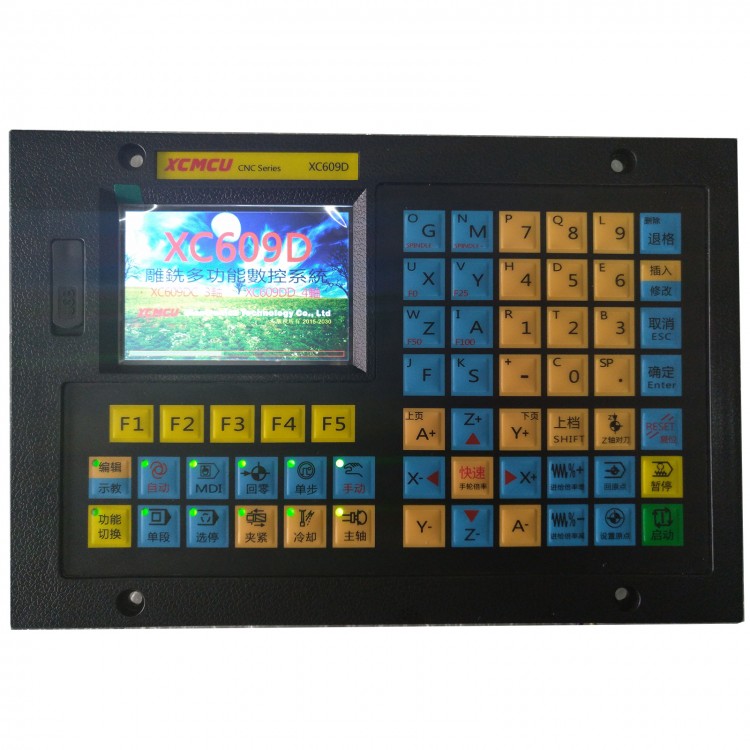

4 Axis CNC Offline Controller Motion Control Stepping Servo Numerical Control w/3.5" LCD XC609DD

Description:

XC609DD numerical control system is perfect for boring, drilling, milling and engraving. With 32-bit high-performance microprocessor, it features real-time multi-task control technology. It is designed with hardware interpolation technology, full linkage, and high-speed algorithm for small lines. Its interpolation accuracy is accurate as 0.001mm, and its speed is 12m/min.

Features:

- Based on 32-bit microprocessor, it supports full linkage and 0.001 mm interpolation accuracy, working at the speed of 12m/min.

- 3.5-Inch Color LCD: 480 x 320 resolution. Equipped with 5 softkeys, it is easy to learn and operate. It offers rich display interfaces for parameter classification, alarm log, system diagnosis and the like. It facilitates debugging and maintenance.

- Using standard G instruction which is compatible with FANUC system instruction.

- 40 kinds of G command codes support cyclical drilling.

- Supports teach-in function.

- Supports tool auto-checking instrument.

- Full screen editing of program for your parts. Built in 256M memory for storing N pieces of parts programs.

- USB Interface: Support reading, writing, data backup and direct processing for your U disk file. (DNC)

- I/O 24/24: It is flexible to use, for its I/O ports can be expanded to 96/96.

- Two Languages: Chinese and English operation interfaces for convenient operation.

- Adopts advanced algorithm for small lines, processing stably.

- Supports fast operation in specified position and multi-coordinate system (automatically saving after power down).

- Supports saving break-point function: It will automatically save by pressing the PAUSE button during operation or after powering off.

- Supports multi-level operation authorization for easy management, featuring time-limited system locking function.

- Supports for G code files of third-party software, including UG, Mastercam, PowerMill, FeatureCAM, ArtCAM, JDPaint, Wentai.

Technical Specifications:

Basic Functions:

- Number of Controlled Axes: 4-Axis(X, Y, Z, A)

- Number of Linkage Axes: Full Linkage

- Analog Spindle: 1

- Spindle Rate: 10% to 150%

- Minimum Instruction Unit: 0.001 mm

- Maximum Instruction Value: ±99999999 x Instruction Unit

- Fast Feed Speed: 12,000mm/min

- Rate of Feed: F0, 25%, 50%, 100%

- Cutting Feed Rate: 12,000mm/min

- Feed Speed Rate: 10% to 150%

- Electronic Gear Ratio: 1-65535:1-65535

- Automatic Acceleration & Deceleration: Yes

- Location: G00 (Linear Interpolation Location)

- Interpolation: Linear (G01), Circular (G02/G03/G12), Spiral-line Interpolation

- Returning to Reference Point: Automatically (G28)

- LCD: 3.5-inch TFT LCD screen with resolution of 480 x 320

- MDI Softkey: 5

- Step Feed Amount: x1, x10, x100

- Communications Interface: U disk interface

- External Handwheel Interface: Yes

- I/O Interface: 24/24 (Extensible to 96/96)

- Pause (seconds): Yes

- Accurate Stop Status: Yes

- Accurate Stop: Yes

- Storage Travel Checking: Yes

- MDI Running: Yes. It supports multi-segment operation

- Reset: Yes

- Jump Switch: Yes

- Single Block Operation: Yes

- Program Protection Switch: Yes

- Self-diagnostic Function: Yes

- Emergency Stop: Yes

- Power Supply: Single-phase AC220V+10%-15%, 50Hz±1Hz. DC24V/1A

- Coordinate Systems: Machine Coordinate System (G53), Workpiece Coordinate System (G92, G54-G59), Local Coordinate System (G52), Plane Designation of Coordinate System

- Automatic Coordinate System Setting: Yes

- Decimal Point Input: Yes

Auxiliary Function:

- Auxiliary functions: M2 digits, M code customization, manual/MDI/automatic control of spindle forward, reverse and stop; control of lubrication to start and stop, etc.

Spindle Functions:

- Spindle Function: Analog Spindle (0-10V)

Editing Operation:

- Editorial Functions: Parameters, Diagnostic Bit Input, Program Editing, MDI Multi-segment Execution

- Storage Capacity: 256M

- Number of Stored Programs: N pcs

- Display of Program Names: Chinese, English, Numbers, and Combinations

- Looking for Program Lines: Yes

- Skip Optional Program Segment: Yes

- Program Switch: Yes

Display:

- Displayed Language: Chinese, English

- Processing Time & Number of Parts: Display

- Spindle Speed, M/S Instruction: Yes

Package Included:

- 1 x XC609DD 4-Axis CNC Offline Controller