| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $222.92 | $218.37 | $211.55 | $202.45 | Contact US |

SWPG Electronic Handwheel 5 Axis Control Wireless MPG CNC Manual Pulse Generator for SIEMENS/FANUC

$159.43

SWPG Electronic Handwheel 5 Axis Control Wireless MPG CNC Manual Pulse Generator for SIEMENS/FANUC

$159.43

ZWPG Electronic Handwheel 4/5/6 Axis Control Wireless MPG CNC Manual Pulse Generator for SIEMENS/FANUC

$155.55

ZWPG Electronic Handwheel 4/5/6 Axis Control Wireless MPG CNC Manual Pulse Generator for SIEMENS/FANUC

$155.55

STWGP 6-Axis CNC MPG Wireless Handwheel E-Stop Manual Pulse Generator + Receiver for SIEMENS MITSUBISHI FANUC FAGOR

$253.60

STWGP 6-Axis CNC MPG Wireless Handwheel E-Stop Manual Pulse Generator + Receiver for SIEMENS MITSUBISHI FANUC FAGOR

$253.60

Introduction:

-

The DDCSV2.1 is the 4 axis and 4 axis motion controller which has been

researched and developed by Faster CNC for four years.The control period

of each position is only 4 milliseconds,with a high control

precision.The highest uniaxial output pulse is 500KHz and the pulse

width can be adjusted.It supports the common stepper motor and servo

motor.

- The DDCSV2.1 numerical control system adopts the ARM+FPGA

design framework.The ARM can finish the part of human-computer interface

and code analysis and the FPGA can finish the part of underlying

algorithm and control pulse generate,with the reasonable design,reliable

control and easy operation.

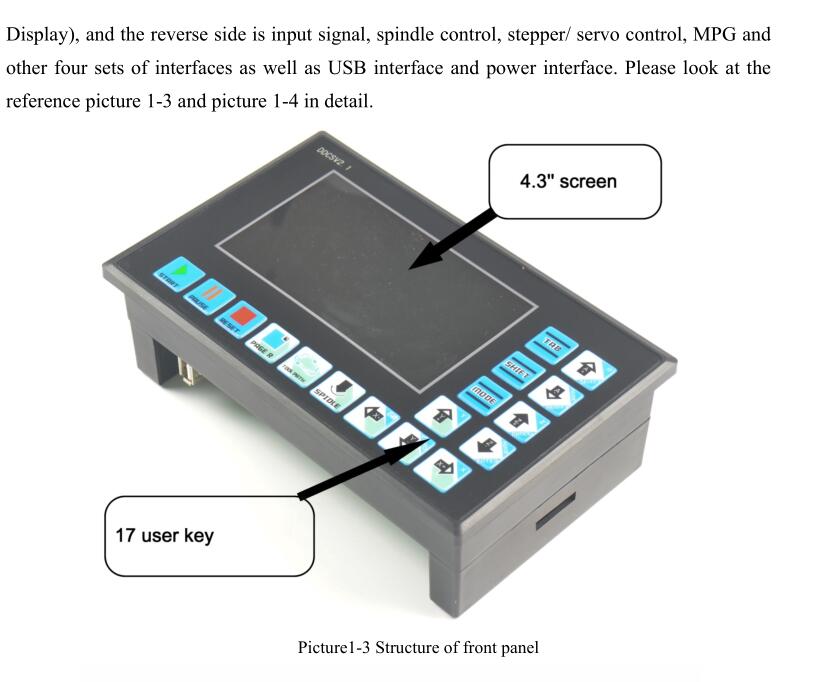

- The panel layout structure of DDCSV2.1

is rational. The common off-line operation can be finished only by 17

keys and it supports the FANUC with high universality to be compatible

with G code set.

- This specification introduces the operation method

of caving machine's special off-line CNC system,DDCSV2.1 and the

machine tool connection as well as operation specification.By lots of

graphical representation and examples,the uses can quickly learn to use

the DDCSV2.1 CNC system.

DDCSV2.1 has made the following changes on the basis of DDCSV1:

1:The input signal is modified to support the NPN switch;

2:Support limit and the home share the input port;

3:Use the more stable FLASH,to ensure that no program loss;

4:Upgrade algorithm,support soft interpolation, modified V1.1 version of arc interpolation bug;

5:Upgrade the power module,the system is more stable.

Performance parameter of Product:

- Ordinary digital input interface of 16-circuitoptocoupler coupling isolation

- Ordinary digital input interface of 3-circuit optocoupler coupling isolation

- Output interface of 0-10V spindle control port with analog quantity(can be modified as PWM output);

- Support the 4 axis stepper motor control,the highest control pulse output of single axis is 500KHz;

- ARM9 main control chip;

- FPGA core algorithm chip;

- 4.3 inches TFT screen, resolution ratio:480*272

- 17 operational keys;

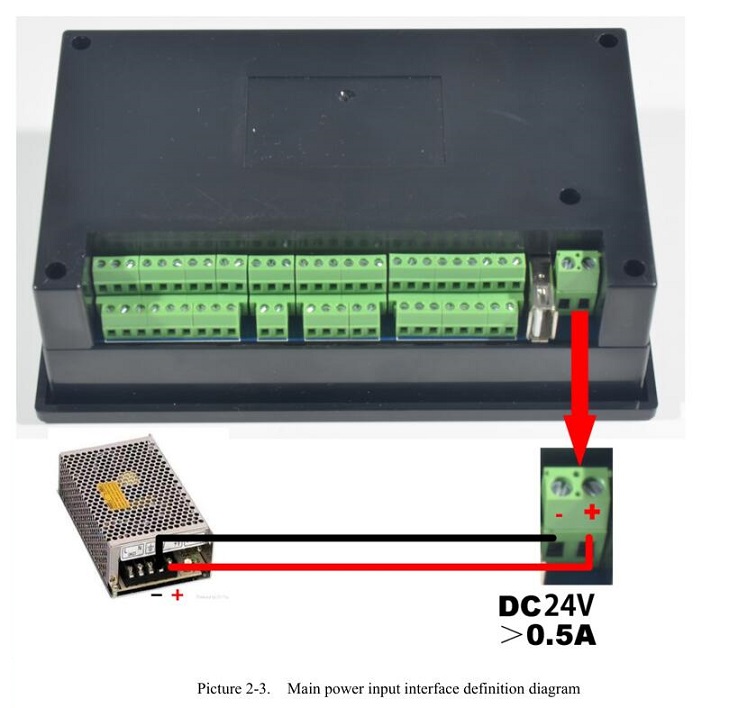

- The main control equipment is 18V-32V power input,the current capacity is required not to be lower than 0.5A;

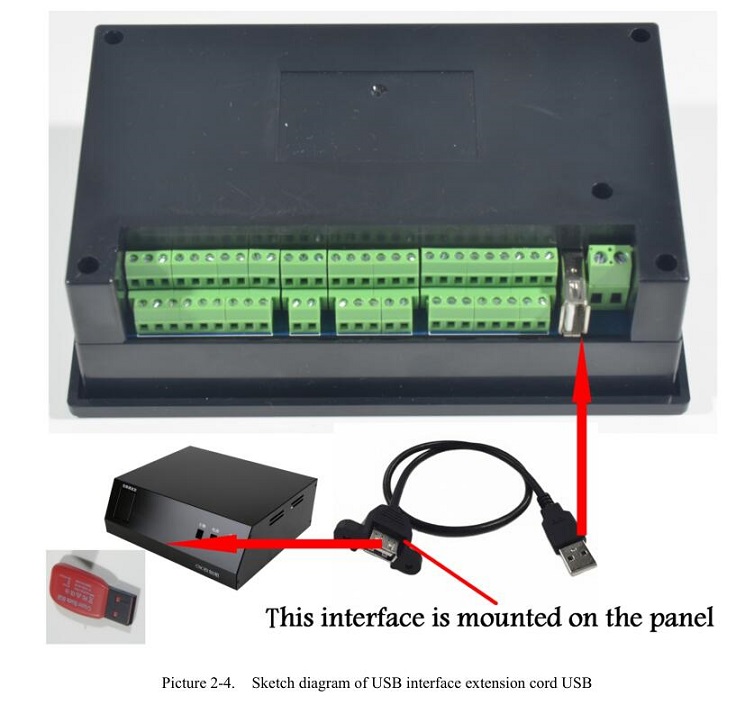

- Support the USB flash disk to read the G code,and the size of G codefile has no requirement;

- Be equipped with MPG port and support digital display MPG as well as support the general MPG in the market.

- Support the panel key with single-axis manual operation,manual step and CONT operation;

- Support the operation of quickly specify the running position;

- Support the multi coordinate systems (with automatically saving function in case of power cut);

-

Support the function of saving data automatically after power down

(press the start to automatically save the data in the operation,

automatically save the data after power down)

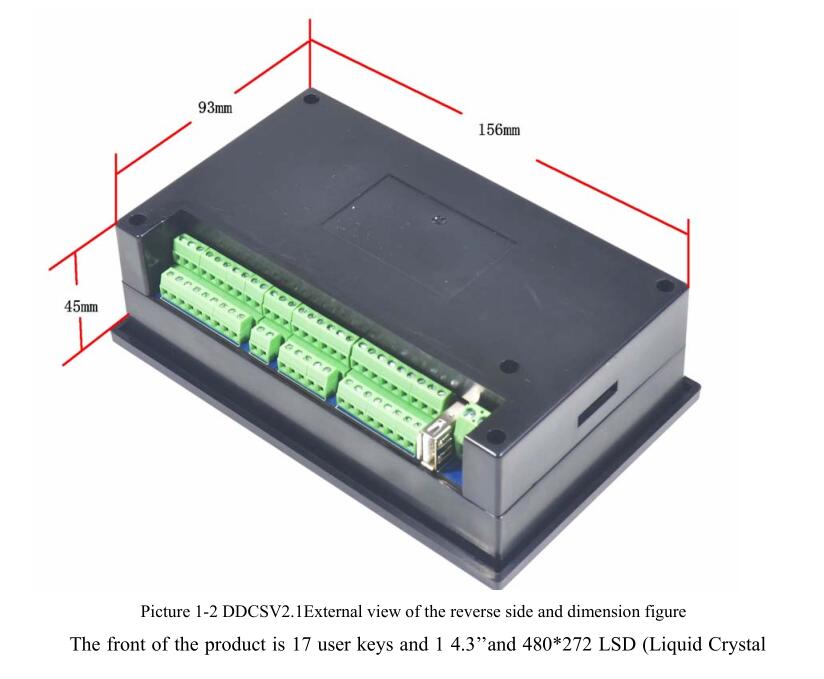

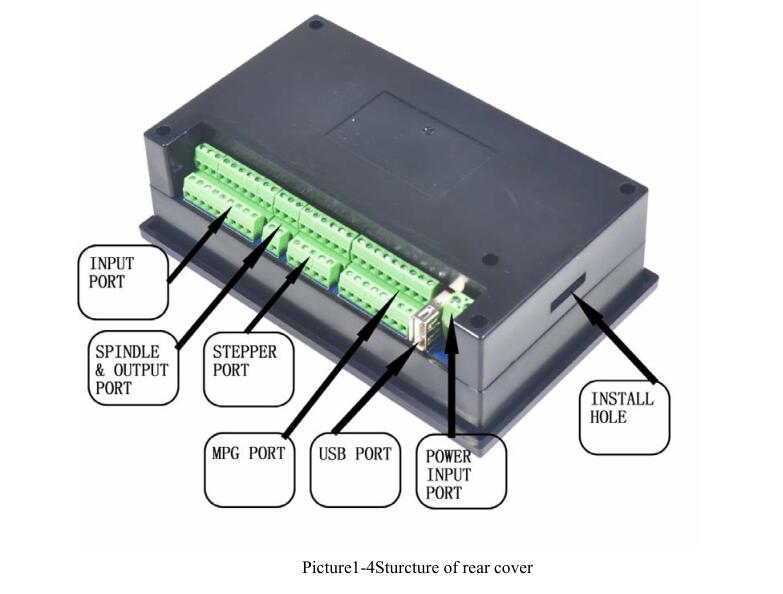

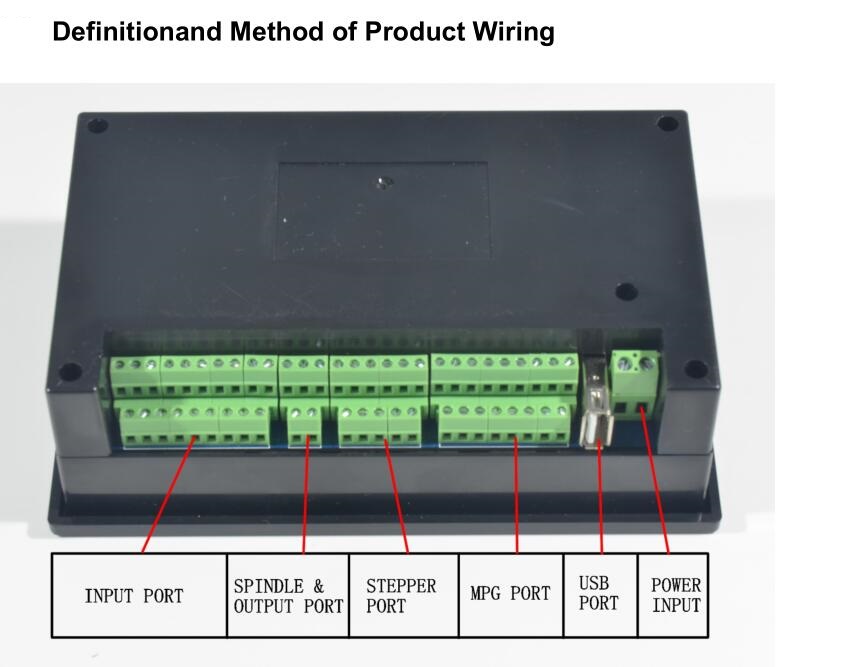

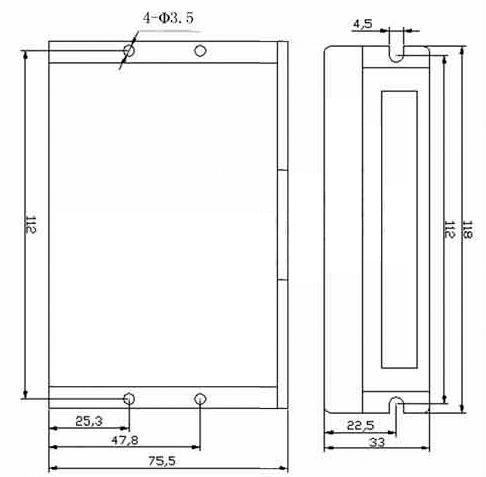

Outward Appearance, Structure and Size of Product:

-

The DDCSV2.1 adopts the embedded shell structure,which can punch a

square hole on the equipment cabinet and then embed this equipment in

the squire hole. Use two locking mechanism from the inside can fix this

equipment on the equipment cabinet,with easy installation.The dimension

figure of the product's outward appearance are as picture 1-1 and

picture 1-2.

- The panel size of the product is 163*102*5mm;The size of main body is 156mm*93mm*45mm;

- The size of square hole installed on the equipment cabinet is 156*93mm.

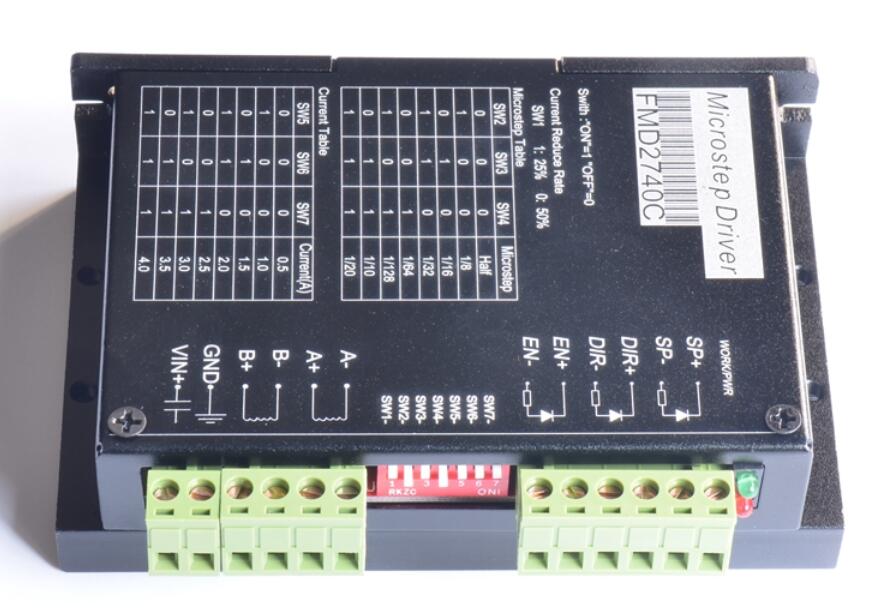

FMD2740C CNC Driver 50V/4A/128 Microstep Hybrid Stepper Motor Driver Controller

Instructions: Click here

Suitable for a variety of small and medium-sized automation equipment

and instruments,for example: Small engraving machine, SMT machine, etc.

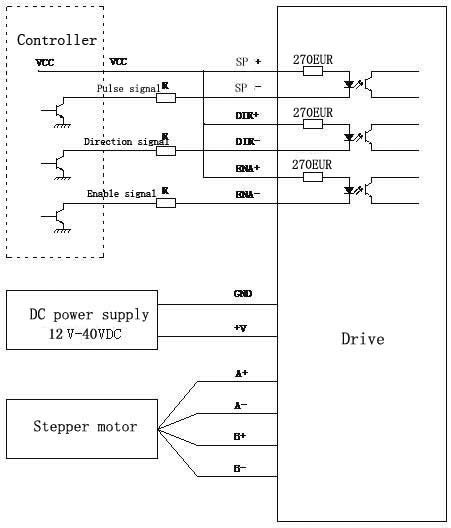

Weak signal interface

|

Signal |

Function |

|

SP+ |

Pulse signal + end |

|

SP- |

Pulse signal - end |

|

DIR+ |

Direction signal +end |

|

DIR- |

Direction signal-end |

|

EN+ |

Enable signal +end |

|

EN- |

Enable signal -end |

Strengths connection port

|

Signal |

Function |

|

VIN+ |

12to50 v dc power supply input +end,it is recommended to use 36V3A |

|

GND |

DC power supply connection ground |

|

A+ |

Stepper motor A + Phase terminal |

|

A- |

Stepper motor A - Phase terminal |

|

B+ |

Stepper motor B+ Phase terminal |

|

B- |

Stepper motor B - Phase terminal |

NOTE: This drive does not contain

anti-anti-interpolation circuit so non-input positive and negative power

supply upside down! Otherwise it will damage the drive!

|

Cooling method |

Natural cooling or forced air cooling |

|

|

Use of the environment |

Occasions |

Avoid dust, oil mist and corrosive gases |

|

Temperature |

0°C-+50°C |

|

|

Humidity |

40-90%RH |

|

|

Vibration |

6m/s2 MAX |

|

|

Storage temperature |

-20°C-+65°C |

|

|

Weight |

250g |

|

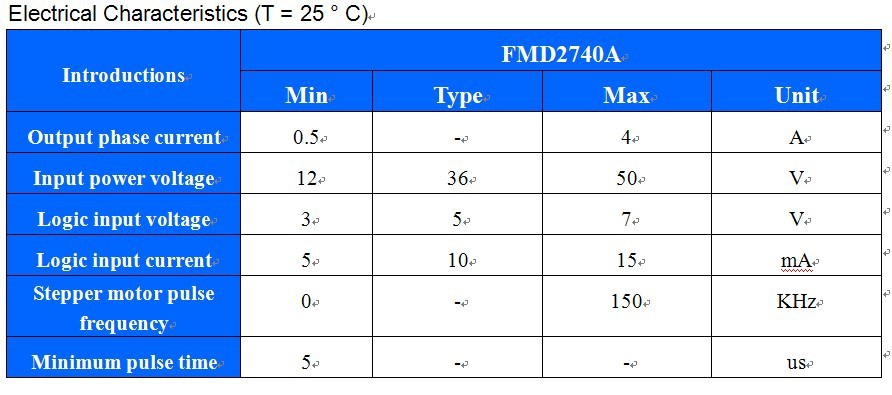

8, Power supply

The supply voltage can work normally in between DC12V-50V, FMD2740A driver can use ordinary switch DC power supply, can also be used for transformer and the bridge rectifier and filter capacitor, capacitance desirable 2000U to 5000U. Note rectified voltage ripple crest does not exceed 50V.Recommended the user to use the 24V-32V DC supply , avoid the grid fluctuations over drive voltage operating range.

Note:

1, Wiring should pay attention to the power of positive and negative Do not be reversed;

2, In order to reduce costs, multiple drives can share a power supply. But it should improve the rated power and rated output current of the power and attention to cooling.

9,Attenuation of the DIP switch settings

|

Decay mode |

SW1 |

SW2 |

|

Slow decay |

OFF |

OFF |

|

Mixed decay |

ON |

OFF |

|

Fast decay |

OFF |

ON |

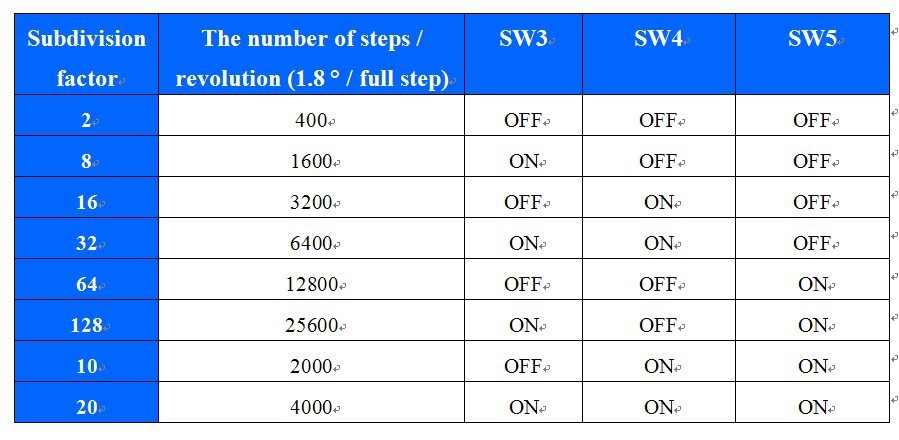

10,Subdivision DIP switch settings

10,Subdivision DIP switch settings

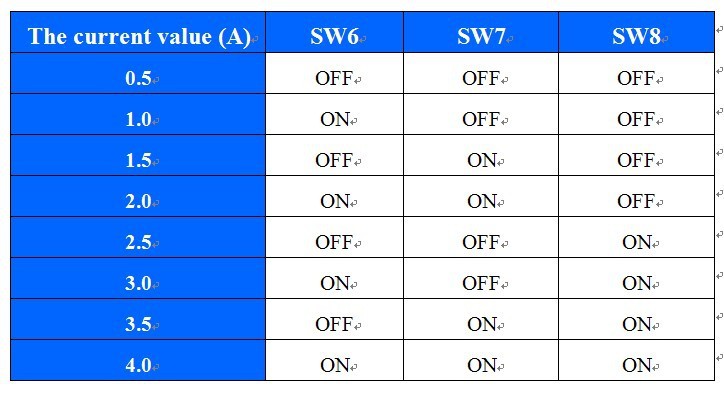

11,Current DIP switch settings

The FMD2740A driver can drive all current 4A 4-wire, 6-wire or 8-wire 2-phase / 4-phase motors, are detailed below 4-wire, 6-wire, 8 wire stepper motor connection:

14,Matching of the drive and motor

FMD2740A driver can drive the domestic and foreign manufacturers of 2-phase or 4-phase motor, in order to obtain the most satisfactory driving, you need to choose a reasonable supply voltage and current setting. Supply voltage determines the level of the high-speed performance of the motor, and the current set value determines the output torque of the motor.

Supply voltage selected

Generally speaking, the higher the supply voltage, the greater the torque motor at high speed, the more it can avoid the high speed out. But another aspect, the voltage is too high will lead to over-voltage protection, and can even damage the drive, but also in the high-pressure work, low speed vibrations.

The output current is set

For the same motor, the greater the current setting, the higher speed, the current motor and drive more heat. So under normal circumstances the current setting into a powered machine warm but not too hot long-term value.

Note: the current settings after you run the motor for 15-30 minutes, if the motor temperature is too high, you should reduce the current settings. If the motor current setting, the motor output torque is not enough to improve heat dissipation conditions to ensure that the motor and drive are not hot

Package List:

- 1 x 4-Axis CNC Motion controller

- 1 x Stepper Motor Controller

- 1 x 8GB USB Flash drive

- 1 x USB Extension Cable