| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $168.86 | $165.42 | $160.25 | $153.36 | Contact US |

ANNOY TOOLS 4.0 3-Axis CNC Controller Board + Offline Controller 1.8" Screen for CNC/Laser Engravers

$42.30

ANNOY TOOLS 4.0 3-Axis CNC Controller Board + Offline Controller 1.8" Screen for CNC/Laser Engravers

$42.30

ANNOY TOOLS 4.0 3-Axis USB CNC Controller Board for 2-Axis Laser Engravers or 3-Axis CNC Engraver

$23.61

ANNOY TOOLS 4.0 3-Axis USB CNC Controller Board for 2-Axis Laser Engravers or 3-Axis CNC Engraver

$23.61

F2300BT 2-Axis CNC Motion Controller Support Torch Height Control for Fangling CNC Flame Plasma Cutting Machines

$510.28

F2300BT 2-Axis CNC Motion Controller Support Torch Height Control for Fangling CNC Flame Plasma Cutting Machines

$510.28

Introduction:

- The DDCSV2.1 is the 4 axis and 4 axis motion controller which has been researched and developed by Faster CNC for four years.The control period of each position is only 4 milliseconds,with a high control precision.The highest uniaxial output pulse is 500KHz and the pulse width can be adjusted.It supports the common stepper motor and servo motor.

- The DDCSV2.1 numerical control system adopts the ARM+FPGA design framework.The ARM can finish the part of human-computer interface and code analysis and the FPGA can finish the part of underlying algorithm and control pulse generate,with the reasonable design,reliable control and easy operation.

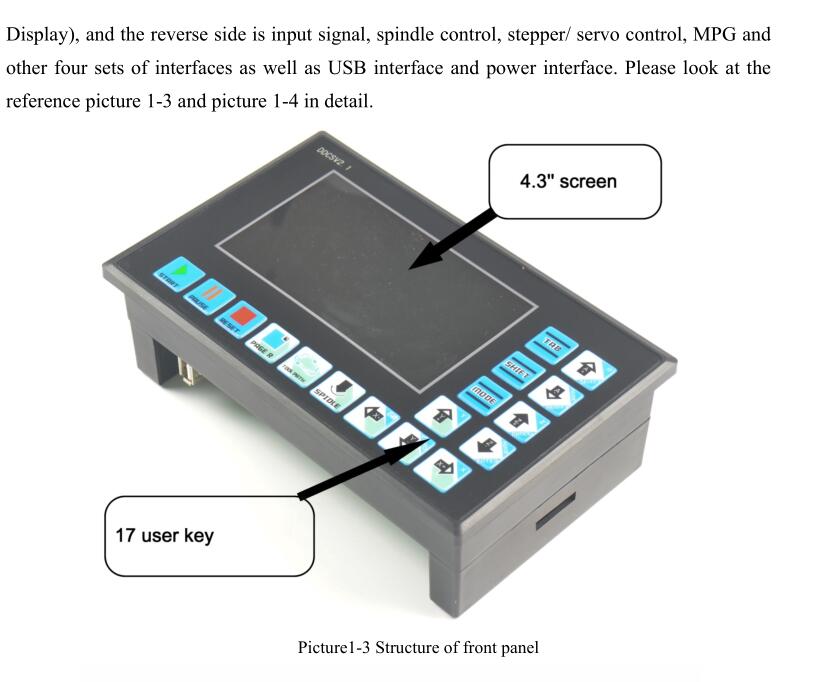

- The panel layout structure of DDCSV2.1 is rational. The common off-line operation can be finished only by 17 keys and it supports the FANUC with high universality to be compatible with G code set.

- This specification introduces the operation method of caving machine's special off-line CNC system,DDCSV2.1 and the machine tool connection as well as operation specification.By lots of graphical representation and examples,the uses can quickly learn to use the DDCSV2.1 CNC system.

DDCSV2.1 has made the following changes on the basis of DDCSV1:

1:The input signal is modified to support the NPN switch;

2:Support limit and the home share the input port;

3:Use the more stable FLASH,to ensure that no program loss;

4:Upgrade algorithm,support soft interpolation, modified V1.1 version of arc interpolation bug;

5:Upgrade the power module,the system is more stable.

Performance parameter of Product:

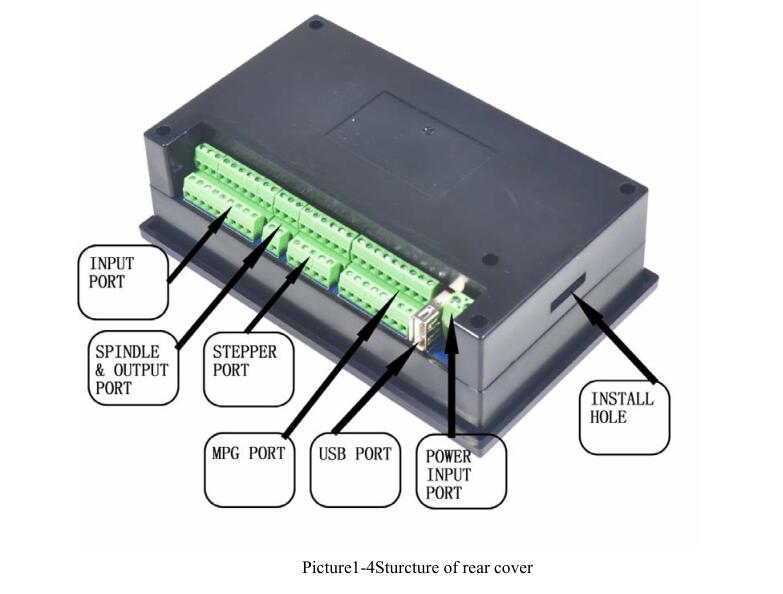

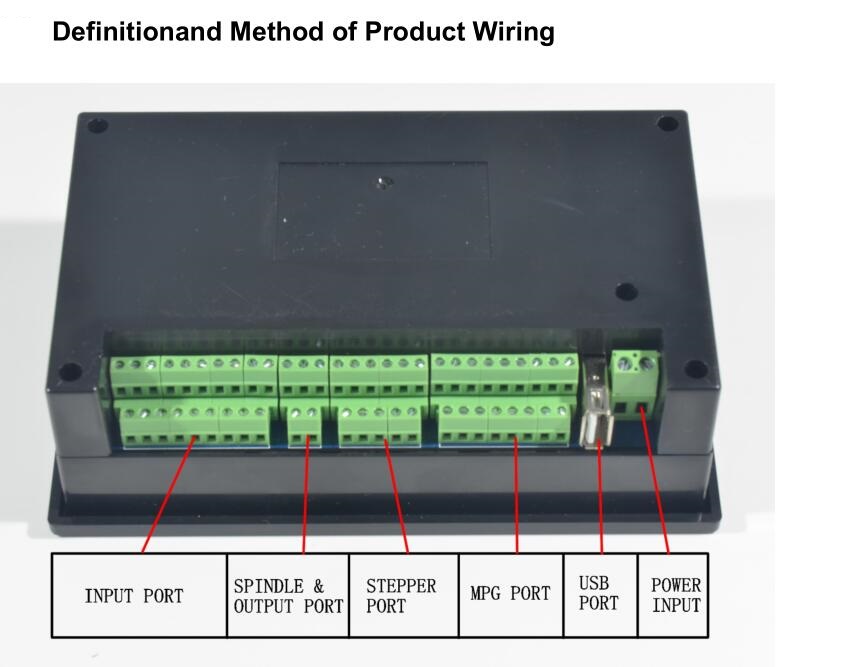

- Ordinary digital input interface of 16-circuitoptocoupler coupling isolation

- Ordinary digital input interface of 3-circuit optocoupler coupling isolation

- Output interface of 0-10V spindle control port with analog quantity(can be modified as PWM output);

- Support the 3 axis,4 axis stepper motor control,the highest control pulse output of single axis is 500KHz;

- ARM9 main control chip;

- FPGA core algorithm chip;

- 4.3 inches TFT screen, resolution ratio:480*272

- 17 operational keys;

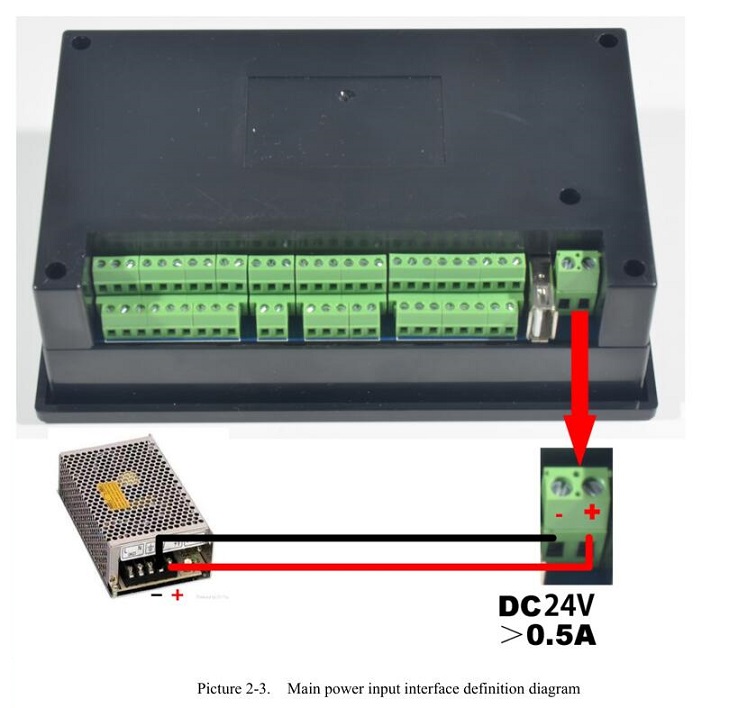

- The main control equipment is 18V-32V power input,the current capacity is required not to be lower than 0.5A;

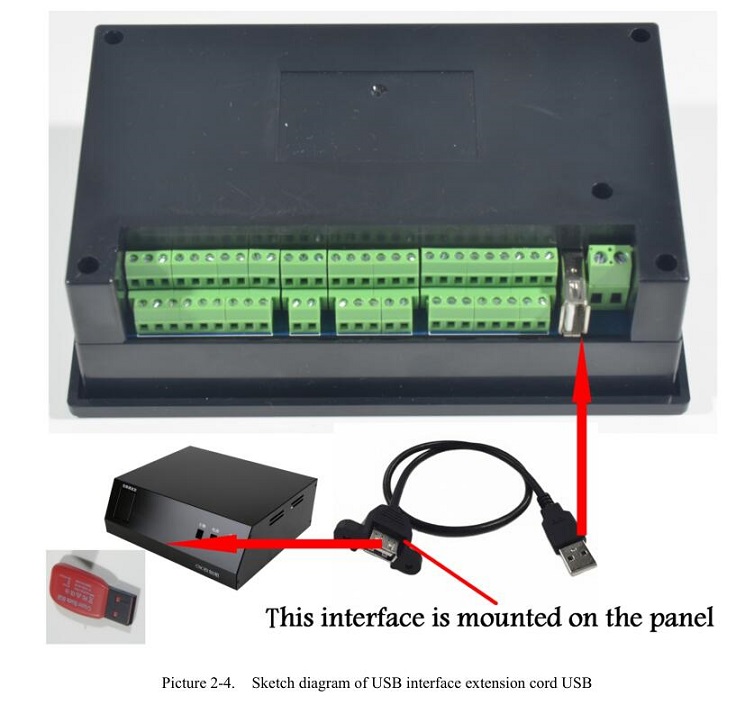

- Support the USB flash disk to read the G code,and the size of G codefile has no requirement;

- Be equipped with MPG port and support digital display MPG as well as support the general MPG in the market.

- Support the panel key with single-axis manual operation,manual step and CONT operation;

- Support the operation of quickly specify the running position;

- Support the multi coordinate systems (with automatically saving function in case of power cut);

- Support the function of saving data automatically after power down (press the start to automatically save the data in the operation, automatically save the data after power down)

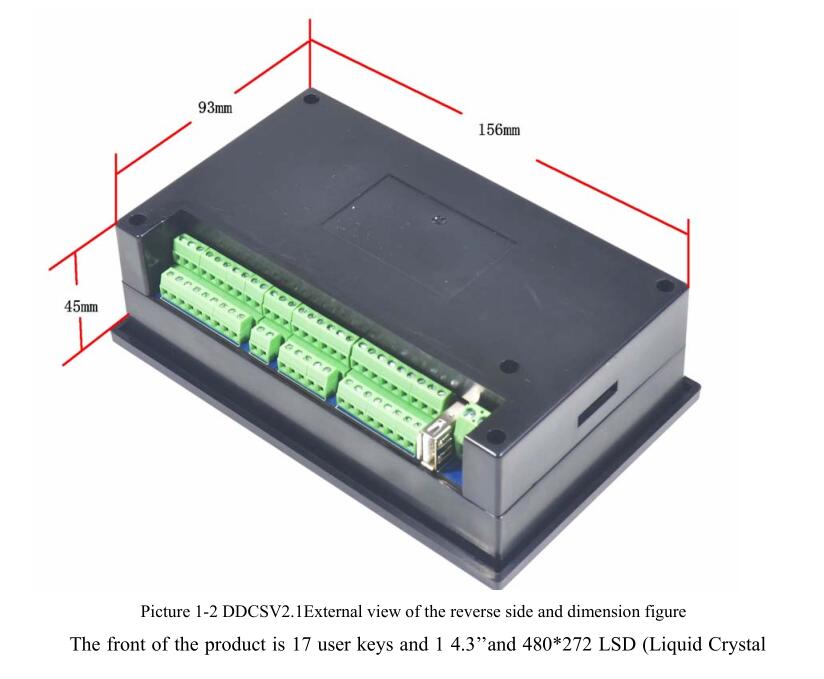

Outward Appearance, Structure and Size of Product:

- The DDCSV2.1 adopts the embedded shell structure,which can punch a square hole on the equipment cabinet and then embed this equipment in the squire hole. Use two locking mechanism from the inside can fix this equipment on the equipment cabinet,with easy installation.The dimension figure of the product's outward appearance are as picture 1-1 and picture 1-2.

- The panel size of the product is 163*102*5mm;The size of main body is 156mm*93mm*45mm;

- The size of square hole installed on the equipment cabinet is 156*93mm.

Package List:

- 1 x 4-Axis CNC Motion controller

- 1 x 4GB USB Flash drive

- 1 x USB Extension Cable