| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $341.40 | $334.44 | $323.98 | $310.05 | Contact US |

XLT-802 Automatic Screw Feeder 1.0-5.0mm Screw Conveyor with Adjustable Guide Rail and Side Speed Adjustment Knob

$112.87

XLT-802 Automatic Screw Feeder 1.0-5.0mm Screw Conveyor with Adjustable Guide Rail and Side Speed Adjustment Knob

$112.87

HM-130HP Dual Action Airbrush 8-85PSI 0.3MM High Performance Quick Release Spray Nozzle Air Pressure Gun

$50.69

HM-130HP Dual Action Airbrush 8-85PSI 0.3MM High Performance Quick Release Spray Nozzle Air Pressure Gun

$50.69

T90C (T65 Tip) Portable Intelligent Soldering Iron IPS LCD Screen 18-130W Soldering Pen with PD 140W Adapter and T65-KU/BC2 Tips

$82.62

T90C (T65 Tip) Portable Intelligent Soldering Iron IPS LCD Screen 18-130W Soldering Pen with PD 140W Adapter and T65-KU/BC2 Tips

$82.62

4KW Induction Heater Kit with Water Pump + 12V Power Supply + 70mL Crucible + 48V 4000W Power Supply

Description:

The induction heater eliminates the need for a third-party power meter, making operation simpler. It features microsecond-level over-current and under-voltage protection, as well as water shortage protection, with the protection type displayed directly on the screen.

It is a small-power induction heating machine, supporting DC 48V 80A power supplies. It is mainly used for heating and quenching small iron-based metal materials. An optional 70mL graphite crucible can reach a maximum temperature of 1600°C, easily melting metals such as iron, copper, gold, silver, and aluminum. Using a custom heating coil, steel with a diameter of up to 10mm can be forged and quenched. The default shipping includes a 60mm diameter heating coil; for quenching and forging, please contact customer service to customize the heating coil.

48V 50A Power Supply:

* Note: The 48V 50A power supply is a disassembled second-hand unit. The casing may have some scratches, but this does not affect normal power output. Each power supply is tested before shipment. No warranty is provided after sale; please understand.

* Due to power supply shortages, original R48-3000e3 power supplies (for Emerson) and ZTE ZXD3000 single-fan or dual-fan power supplies will be shipped randomly. Except for the appearance, all other parameters including weight are completely identical among the three types.

Features:

* Uses a 1.6mm thick military-grade PCB with 20oz copper; high current capacity and excellent heat dissipation

* 12038 high-power cooling fan

* Custom extra-large high-power heatsink to ensure MOSFET cooling

* Output terminal uses 12pcs M4 copper posts in parallel; besides connecting the heating coil, it can also connect high-voltage transformers or high-frequency transformers

* Uses 8 original IRFP260 MOSFETs and 18 original BM capacitors in parallel resonance for high power and efficiency

* The product can operate continuously for long periods under proper cooling conditions

* Integrated design of power meter and control system for convenient use

* Integrated control avoids complex wiring

* Heating coil is wrapped with high-temperature insulation material to prevent short circuits during heating.

* Microsecond-level fast over-current protection automatically cuts off the heating protection circuit if overload occurs.

* Color LCD displays all operating parameters, including voltage, current, power, working status, and alarm types. A potentiometer sets the maximum allowable current and minimum input voltage. If the current exceeds the maximum or voltage falls below the minimum during operation, the system immediately enters overload protection mode and locks operation; manual reset is required before restarting.

* Button control, with optional foot pedal connection for convenient use in different scenarios

* Water-cooling system with water shortage protection

Specifications:

* Dimensions: 257mm × 180mm × 96mm

* Operating Voltage: DC 12V–60V (Recommended: DC 48V)

* Maximum Operating Voltage: 60V DC

* Maximum Operating Power: 4000W

* Maximum Operating Current: 80A

* Heating Coil Inner Diameter: 60mm

Precautions:

1. Under no circumstances should the unit be powered on without a load (a no-load condition means the output terminals are not connected to any load). Powering on under no-load will generate high-frequency noise and can permanently damage the MOSFETs, which cannot be repaired.

2. Induction heating produces very high power. In addition to the PCB and electronic components generating heat, the heating coil itself becomes very hot. To avoid burning the heating coil and damaging the system, always use a cooling water pump with the heating coil.

3. It is recommended to use a power supply that meets the required specifications; otherwise, under-voltage protection may trigger during use. Minimum recommended power: 12V > 800W, 24V > 1500W, 36V > 3000W, 48V > 5000W. At any voltage, as long as the operating current is kept below 100A, the circuit will not be damaged. The maximum current can be set to 100A via the potentiometer. High-power operation naturally generates heat, so proper cooling must be ensured.

4. Set the under-voltage point no lower than 12V, and the over-current point no higher than 100A. High-power operation generates heat, so ensure proper cooling.

5. During operation, the heating coil produces very high temperatures. Water-cooling is strongly recommended to protect the PCB. If possible, use cold water input and discharge hot water into a drain.

6. The power input terminals are marked with + and – signs. Do not reverse the polarity.

7. Never power on without a load (here, no-load means the output is not connected to any load; connecting the heating ring without heating an object does not count as no-load).

8. When using a graphite crucible, a non-recirculating water-cooling method must be used: cold water enters, hot water is discharged into a drain. This prevents prolonged high water temperatures from reducing the system's lifespan. Even during long periods of high-power operation, this water-cooling method should be used. After heating, if the crucible has not been removed from the heating ring, do not disconnect the 12V auxiliary power, otherwise the water pump will stop and the heating ring may be damaged by the crucible's residual heat.

Packing List:

* 1 × Mainboard

* 1 × Heating Coil

* 1 × Water Pump

* 1 × Water Pump Hose

* 1 × 12V 2A Power Supply

* 1 × 70mL Crucible

* 1 × DC 48V 4000W Power Supply

* 1 × Air Switch

* 1 × Power Connector

* 1 × Power Cable

* 2 × Red Wires

* 2 × Black Wires

Packaging Details:

* Weight: 8kg

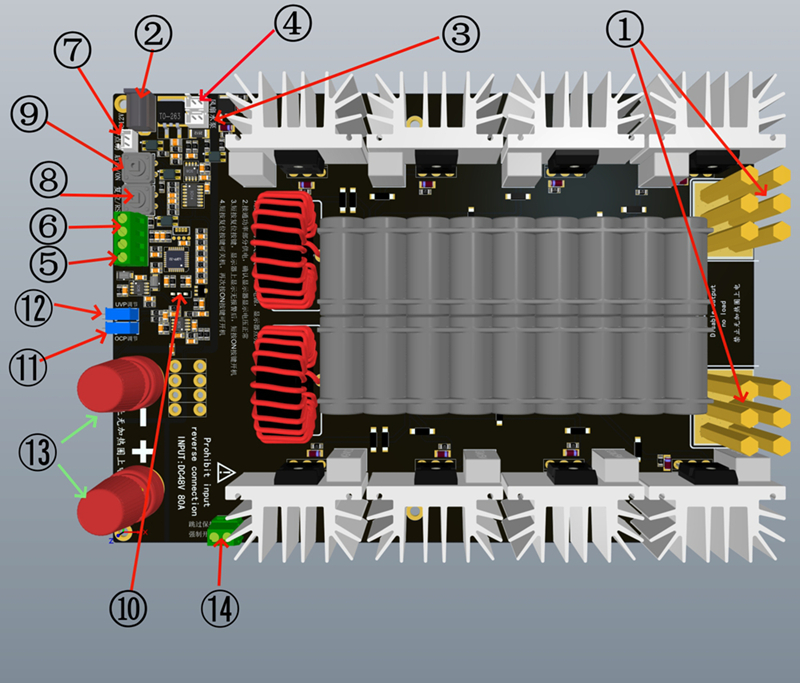

Interface Description:

① Heating Coil Output Interface (Must be connected correctly according to the wiring diagram)

② DC 12V 2A Power Supply Interface

③ Water Pump Interface (Must use the matching water pump)

④ Onboard Fan Interface

⑤ External Reset Interface (Same function as ⑧; reserved for remote control)

⑥ External ON Interface (Same function as ⑨; reserved for remote control)

⑦ External Jog Interface (For foot pedal switch or similar; press your switch to power on, release the switch to power off)

⑧ Reset Button (Turn off heating or clear alarms)

⑨ ON Button (Start heating)

⑩ Water-Cooling Alarm Switch Selection (When using your own water pump, you can disable the onboard water-cooling alarm)

⑪ OCP Adjustment Potentiometer

⑫ UVP Adjustment Potentiometer

⑬ DC 48V Input Interface

⑭ Forced Power-On Interface (Connecting a switch allows forced startup bypassing alarms; see user manual for details)

Usage Instructions:

1. Connect all wires according to the wiring diagram. Check carefully—do not connect incorrectly. (The fan and support posts are shipped separately from the mainboard and must be assembled correctly according to the wiring diagram.)

2. First, connect the 12V 2A power supply to AC 110V–220V. Check whether the water pump and fan operate normally and whether the display screen lights up.

3. If the water pump, fan, and display are all functioning correctly, connect the DC 48V power supply to AC 220V. Wait a few seconds and then turn on the air switch (optional) to check whether the mainboard display shows approximately 48V.

4. If the voltage reading is normal, press the Reset button to clear any startup alarms. Once the display shows no alarms, press the ON button to start heating. The green indicator light will illuminate, and the display will show current and status as ON, indicating that heating has started.

5. To turn off heating, press the Reset button. The green indicator light will go off, the ammeter will return to zero, and the display will show OFF.

6. The heating board has overload protection and water shortage protection. If the water pump malfunctions or lacks water, the system will automatically cut off heating, and the display will show Water Shortage. If over-current occurs, the display shows Over-current, and if the input voltage is too low, it shows Under-voltage.

7. The forced power-on switch at position ⑭ can be used to start the system when the alarm system fails or the control circuit is damaged. When using this function, always monitor the water-cooling system. If water is interrupted during use, the board may be damaged.

8. If the red indicator light turns on and heating stops during use, troubleshoot according to the alarm type displayed on the screen.

9. If heating stops due to current, voltage, or power alarms, after the alarm is cleared, you must manually press the Reset button to clear the alarm before restarting heating.

10. External interfaces ⑤, ⑥ , and ⑦ require self-reset switches (For example, a foot pedal switch: press the switch once, and it will automatically spring back).

11. The maximum current and minimum input voltage alarms can be set via potentiometers ⑪ and ⑫ . After connecting the 12V DC power, adjust the potentiometers while monitoring real-time values on the display. OCP is the over-current point, and UVP is the under-voltage point.