| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $479.45 | $469.66 | $454.98 | $435.41 | Contact US |

ANNOY TOOLS 4.0 3-Axis CNC Controller Board + Offline Controller 1.8" Screen for CNC/Laser Engravers

$42.30

ANNOY TOOLS 4.0 3-Axis CNC Controller Board + Offline Controller 1.8" Screen for CNC/Laser Engravers

$42.30

ANNOY TOOLS 4.0 3-Axis USB CNC Controller Board for 2-Axis Laser Engravers or 3-Axis CNC Engraver

$23.61

ANNOY TOOLS 4.0 3-Axis USB CNC Controller Board for 2-Axis Laser Engravers or 3-Axis CNC Engraver

$23.61

F2300BT 2-Axis CNC Motion Controller Support Torch Height Control for Fangling CNC Flame Plasma Cutting Machines

$510.28

F2300BT 2-Axis CNC Motion Controller Support Torch Height Control for Fangling CNC Flame Plasma Cutting Machines

$510.28

F2300A 2-Axis CNC Control System & F1521 Remote Controller for Flame Plasma Gantry Cutting Machines

Description:

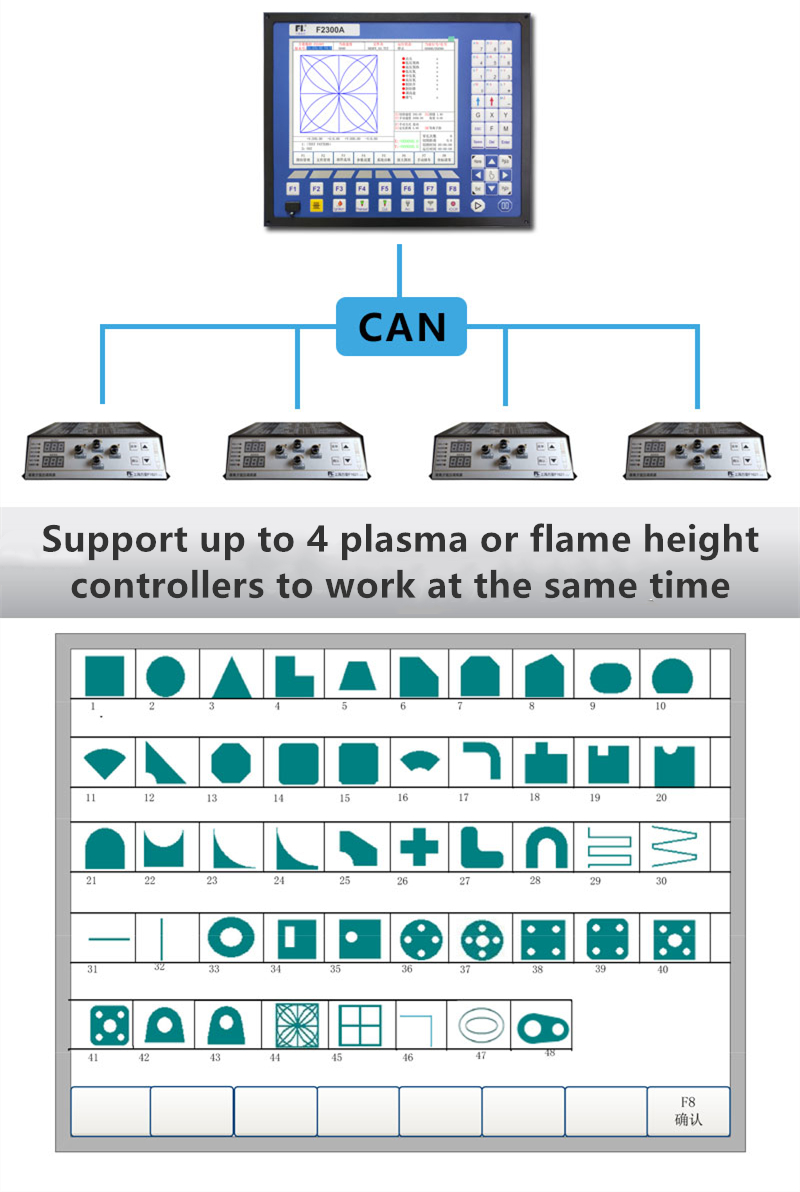

The new system adds a CAN interface. Its CAN bus interface supports F1521 remote control and height controller. It is simple and convenient to wire. Its installation dimensions, interfaces, parameters and functions of the new system are exactly the same as those of the old model, which can completely replace the old system.

It can be used in CNC flame cutting machine equipment and CNC plasma cutting machine equipment, CNC flame plasma dual-purpose cutting machine equipment.

Precautions:

- Keep your hands and feet away from moving machines, control operations or manuals can be done through the front panel keyboard.

- Do not wear loose clothing and clothing such as wire rope when operating the machine to prevent it from being caught by the machine.

- This equipment should and should only be operated by trained personnel.

- It is not a technician authorized by the company. It is strictly forbidden to dismantle the machine.

- When using, do not splash acidic, alkaline, corrosive and other items on the control system.

High Piezoelectric:

- Electric shock can hurt people to death. It must be installed in accordance with the steps and requirements of the packing parts.

- When the power is turned on, you cannot touch the wires and cables.

- This equipment should and should only be operated by trained personnel.

F2300A Hardware Configuration:

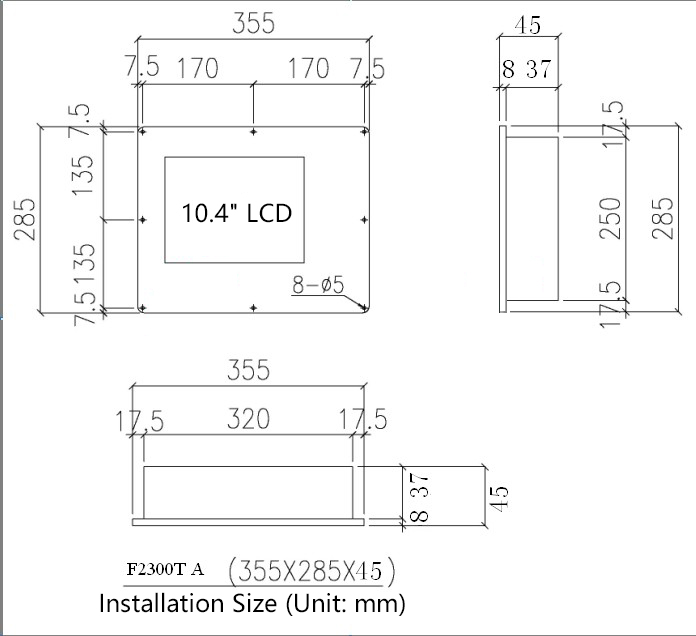

1. Display: 10.4" 800*600 high resolution 16 million color high brightness LCD screen

2. Memory: 64M SDRAM

3. User program space: 256M

4. Main frequency: 400MHZ system main frequency

5. USB: USB1.1 interface front, at least support 16GB USB flash drive

6. Keyboard: PCB film keyboard

7. Chassis: All steel structure is completely shielded, which can truly achieve anti-electromagnetic radiation, anti-interference and anti-static

System Interface:

a) DB15 core male connector two-axis motor drive interface

b) DB25 core female connector, 16 opto-isolated outputs, the maximum reverse current is 300mA

c) DB25 core male connector 16-channel photoelectric isolation input, the maximum input current is 300mA

d) The front panel has a built-in USB interface, which is convenient for users to transmit cutting codes

Basic Parameters and Configuration:

- Main control MCU: industrial grade ARM9 chip

- Number of control axes: 2-axis linkage (3-axis can be customized)

- Maximum program lines: 150,000 lines

- Maximum single program: 4M

- File storage: electronic storage disk, 512M

- User program space: 256M

- Control accuracy: ±0.001mm

- Coordinate range: ±99999.99mm

- Maximum pulse frequency: 250KHz; Maximum running speed: 25m/min

- Time class resolution: 10ms

- System working power: DC+24V DC power input

- System working environment: temperature 0℃ to +55℃; relative humidity 0-95% non-condensing

- External interface: USB

- Keyboard: PCB film keyboard, PS/2 interface, Omron button

- Chassis: All metal structure is completely shielded, anti-electromagnetic radiation, anti-interference, anti-static

- Special configuration: All F2000 series can be equipped with touch screen, 100m wireless remote control, wired hand control box

- Support oxygen gas, plasma, dusting, demonstration

- Up to 45 common graphics libraries

- Graphic scale, rotation, mirroring

- Graphic matrix, interleave, repeat arrangement

- According to the thickness of the steel plate, the speed can be automatically limited at the corner to effectively prevent over-burning

- Switch between metric and imperial

- Graphic steel plate correction

- Customizable coordinate system

- Customizable IO

- System and parameter backup, online upgrade

- Full Chinese/foreign language (English, Japanese, Russian, French, other customized languages) operation menu, one-key switch language

- line selection and number selection

- Support edge cutting, offset cutting

- With power-off, break-point protection memory function

- Dynamic/static processing graphics display, graphics zoom in/out, dynamic tracking of cutting points in zoomed-in state

- With power-off, break-point protection memory function

- For Wentai, TYPEIII, PM2000 and other special nesting software

- Encryption and decryption function: Different administrative rights and corresponding passwords can be set to maintain the rights and interests of the management

F1521 Remote Controller:

Note:

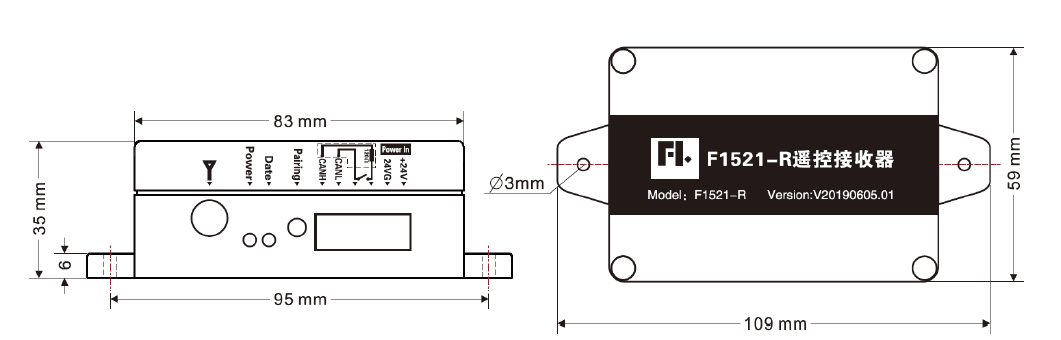

1. The remote control receiver can withstand the instantaneous voltage up to 36V;

2. The input voltage requires Fangyi to provide a constant voltage. If the voltage fluctuation is too large (the instantaneous voltage is greater than 36V), it will cause the actual voltage to be too high and burn the fuse or other original devices inside the transmitter.

Specifications:

- 433MHz free ISM band free of license trial

- The remote control distance is more than 200m, at least not less than 0.5m/1.6ft

- Hardware error detection, software optimization algorithm, two-way communication to ensure stable and reliable communication

- The receiving module f1521 is connected by CAN bus, which is convenient for users to connect

- It is upgraded from F1510, and the accuracy is higher and the signal is better.

Package Included:

- 1 x F2300A CNC Controller System

- 1 x F1521 Remote Controller

- 1 x F1521-R Receiver

- 1 x Cable