| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $143.50 | $140.57 | $136.18 | $130.32 | Contact US |

Hiwonder 6CH Bluetooth Servo Controller Bluetooth 4.0 for Robotic Arm, Biped Robot & PS2 Controller

$27.92

Hiwonder 6CH Bluetooth Servo Controller Bluetooth 4.0 for Robotic Arm, Biped Robot & PS2 Controller

$27.92

Hiwonder Universal Bus Servo Controller Board for PS2 Controller/Bluetooth Module/Robotic Arm/Robot

$29.98

Hiwonder Universal Bus Servo Controller Board for PS2 Controller/Bluetooth Module/Robotic Arm/Robot

$29.98

Hiwonder 6-Channel Servo Controller Board w/ Knobs & Over-Current Protection for Robot & Robotic Arm

$19.68

Hiwonder 6-Channel Servo Controller Board w/ Knobs & Over-Current Protection for Robot & Robotic Arm

$19.68

FEETECH SM60CL 60KG Bus Servo 360-degree Dual Shaft All Metal Servo with URT-1 Debugger Board

Features:

- The servo with integrated structure: Reduction gear + drive motor + sensor + control board + bus communication. New concept power execution module is developed based on high reliability, scalability and basic functions.

- Acceleration start and stop: Compared with ordinary servos, SM60CL can achieve acceleration start and stop. This is similar to automatic car starting and stopping. It can reduce the instantaneous bite force of the gear, reduce the impact force caused by the output shaft due to the moment of stopping, and improve the service life of the servo.

- Can be installed at any angle. When installing the servo to your device, you do not need to find the middle position, you can install it at any angle. Calibrate the current position to the midpoint with one click by modifying the parameters. Reduce the installation process, reduce the error rate, improve the efficiency of mass production and reduce the cost of manual maintenance. The parameters can be adjusted by the software for FD.

- Multi-turn large angle: SM60CL can achieve plus or minus 7 turns at the highest angular resolution, adjust the angle resolution, and can achieve plus or minus 100+ turns. It can realize more scenario applications and modular design shortens the development cycle.

- Parameter feedback and multi-layered protection: The bus servo has the following parameter feedback mechanisms: temperature, load, speed, current, voltage, position, over-temperature, overload, over-voltage and over-current protection. With the software, you can monitor parameter changes in real time. While the device is running, you can dynamically monitor changes in the data. When the internal and external environment changes (such as torque overrun, stall, temperature overrun, etc.), it will make the protection mechanism worked, thereby protecting the servo itself. Closed-loop design, dynamic monitoring, servo protection, and longer service life.

- Open PID motor parameter debugging: It adopts high-precision brushed coreless motor and open PID to debug motor motion effects, such as motor motion hardness, static error compensation, overshoot and others. It can achieve a motor motion effect that is more in line with the set.

- Magnetic encoder sensors: 12-bit high-precision sensor is used to measure position.

- High resolution: non-contact absolute 12-bit encoder (360° 0.088°).

- Serial bus type: support serial bus daisy connection and 254 ID addresses to choose.

- Position servo control mode: can rotate 0~360° and multi-turn at any absolute angle.

- Speed control mode: constant speed control of continuous rotation in the forward and reverse directions, with wide speed regulation range.

- Constant speed motor mode: can output constant speed to achieve forward and reverse direction control.

Note:

- To achieve the above functions, it is recommended to use a URT-1 debug board, and the firmware can be debugged, modified and upgraded by connecting with a PC and running the software for FD.

Functional Application:

- Switching device

- Traction mechanism

- Clamping device

- Educational DIY

- Robotic joints

- Bezel device

- Multi-turn turns

- Point control device

- Steering mechanism

- Wheel mode

- Lifting device

- Robotic arm joints

Service Support:

- Provide software for FD to debug (requiring URT-1 board)

- Provide 3D drawings

- Offer communication protocol

Application Industries:

- Logistics: transport equipment, shuttles, etc.

- Medical equipment: cell sorter, mechanical surgical arms, etc.

- Smart home: movable cameras, smart toilets, etc.

- Robotics: robot joints, robotic arms, etc.

- Military field: gun target steering, rover and the like

- Intelligent equipment: intelligent storage, manufacturing machines, etc.

Specifications:

- Servo model: SM60CL

- Dimensions: 62 x 34 x 40mm/2.4 x 1.3 x 1.6"

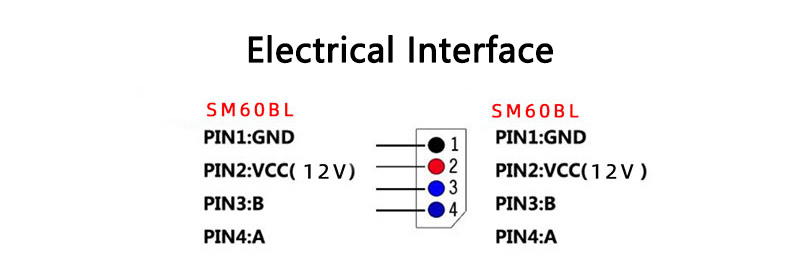

- Working voltage: 12~24V

- Working temperature: -20°C to 80°C

- Quiescent current: 40mA at 12V

- No-load current: 200mA at 12V

- Stall current: 2600mA at 12V

- Stall torque: 60kg.cm at 12V

- Position range: -360°*7 to 360°*7

- Motor type: Brushed coreless

- Weight: 180g/0.4lb

- Sensor: 12-bit high-precision magnetic encoder

- Baud rate: 38400~1000000

- Control frequency: 333Hz

- Position resolution: 0.088°

- Gear reduction ratio: 253:1

- Maximum speed: 35RPM

- Rated torque: 20kg.cm(2N.m) at 12V

- Control mode: position servo/speed control/PWM control

- Parameter feedback: load/position/speed/input voltage/current/temperature

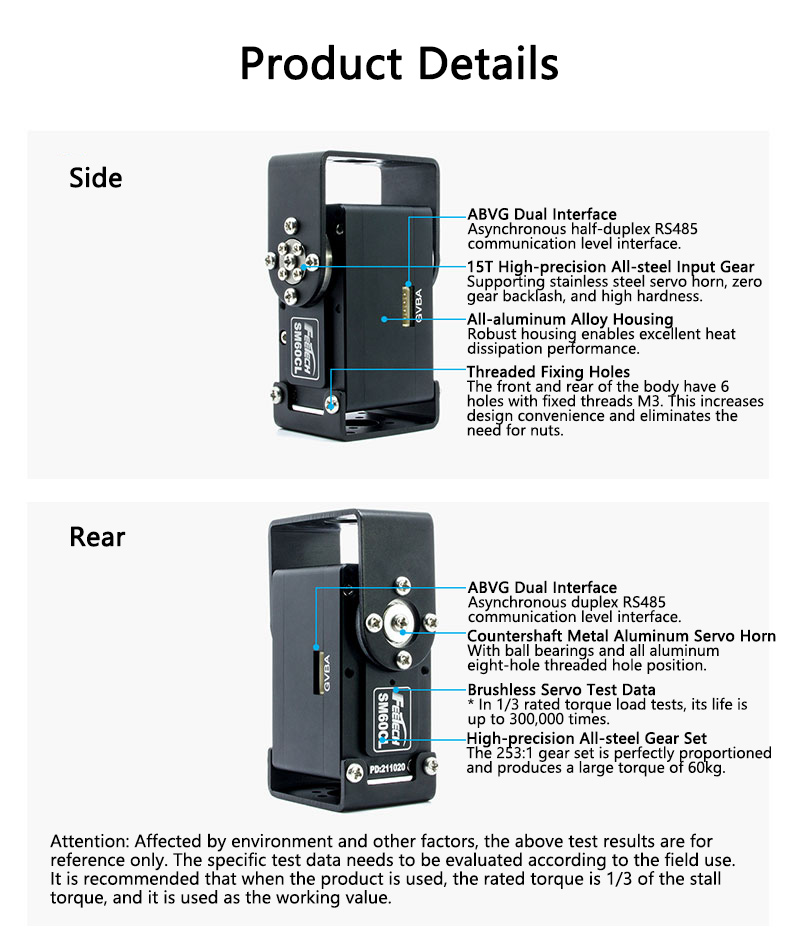

Attention:

(1) When working continuously within 3A current, the SM60CL serial servo will reach the maximum safe working temperature.

(2) Under the quiescent working current, the SM60CL serial servo is energized, but it does not move.

(3) Under the condition of no-load current operation, the SM60CL serial servo moves under the condition of no load.

(4) Under the condition of stalled current, this is the current of the servo at the maximum torque output.

(5) The baud rate can be modified to 500K, 250K, 128000, 115200, 76800, 57600 and 38400.

(6) The actual maximum number of bus nodes available depends on the power supply capacity and the allowable current specification of the cable. It is recommended that 8 groups of servos be equipped with one group of power supply.

(7) The stall torque is the maximum stall torque of the servo, and 1/3-1/5 of this value is selected as the suitable working point for the actual working torque.

Development Environment:

- Can be developed in environments for Arduino/STM32/PC/JAVA/C++/C#.

- Communication protocol, memory table, serial port debugging assistant and other information can be provided.

Package Included:

- 1 x Bus Servo

- 2 x Cables

- 8 x Screws

- 1 x User Manual

- 1 x URT-1 Debugger Board

- 1 x USB Cable