KC9650B 2450M Solid State Microwave Source Exciter Seed Source Supports 1~60W Adjustable Power

Description:

This is an instrument-grade low-power microwave source. It can provide a maximum continuous output power of about 50W and can be flexibly adjusted over a wide range. At the same time, it has extremely high frequency stability and setting accuracy. And it can accurately adjust the frequency in 1Hz steps.

It has good output quality, low phase noise and parasitic amplitude modulation of less than 1%. And phase noise is controlled. The peak power meter can be used to correctly detect its signal. When used to form a microwave measurement system, it can simplify the detection circuit.

The product uses temperature compensation and closed-loop control (ALC), and the drift is very small in the cooling surface temperature range of 0~50℃, usually not exceeding 0.5dB. The cooling method is more flexible, and the heat dissipation interface is a large-area plane. It can be connected to a water-cooled plate or an air-cooled radiator. The device provides a 12V power output and can drive the fan by itself without the need for an additional fan power supply.

It is powered by a single 30V power supply, has a built-in working power supply, and is easy to operate. It supports analog or digital control, including USB, RS485 and network control.

It is suitable for scientific experiments and industrial purposes with general reliability requirements. And it can be used as an exciter for other microwave sources.

Features:

* 2.4~2.5GHz frequency range

* 1ppm frequency stability

* 1Hz frequency resolution

* 1~60W adjustable power

* 0.5dB power uncertainty (typical value)

* 100% reflection protection

* Flexible cooling method

* Rich control interface

Applicable Fields:

* Scientific research

* Radio measurement

* Industrial microwave system

Data Interface:

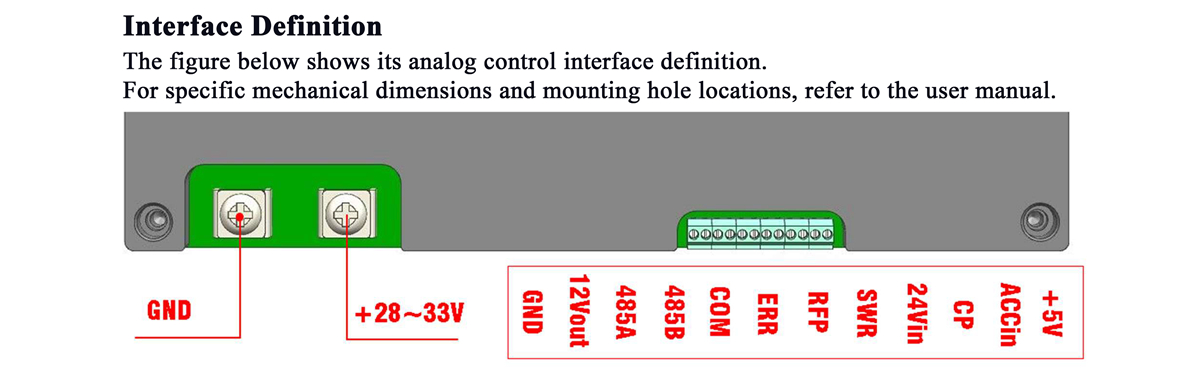

The data interface is mainly used by users to set working parameters (such as frequency, power and IP address), and can preset working parameters to facilitate analog control. The RS485 interface is used to receive instructions from industrial control equipment and can accommodate up to 200 power sources on one bus.

Its RS485 wiring is very simple. You only need to connect 485+ and 485- to A and B on the instrument. Please note that the A and B terminals of PLCs from different manufacturers may have different definitions. If the polarity is opposite, you need to swap them. According to the length of the 485 line and the number of sensors, you need to use an appropriate load resistor.

The power source requires a larger supply current, so the power cable should be selected according to the peak power of 10A, and the cable connector should be fastened with bolts. When using USB control, pay attention to the common ground of the host computer and the power supply to avoid damage to the control equipment.

For the communication protocol of the data interface, please refer to the user manual.

Installation Instructions:

There are 4 screw holes at the four corners of its housing, which are usually installed in the device using Φ4mm screws. If the installation screw holes do not match the device, please use an adapter aluminum plate and do not drill holes on the power source. Pay special attention to the heat dissipation design. The product does not come with a heat sink by default when it leaves the factory, and an external heat sink must be installed. The entire bottom surface is the heat dissipation surface, which should be completely fitted with the heat sink. A small amount of thermal grease can be applied to the fitting surface, or a thin thermal pad can be used to enhance thermal coupling.

The mounting surface should be flat and clean, with a temperature not higher than 50°C, preferably not higher than 30°C. The heat sink should be designed for a heat load of at least 200W, and its temperature rise should not exceed 0.05°C/W.

In places with large vibrations, soft coaxial cables should be used to connect the RF ports. RF coaxial cables will attenuate the signal, so short cables should be used as much as possible and their power loss should be compensated appropriately. The cables should not be too thick to avoid prying the connectors.

Considering that the leakage energy of high-power microwave applications may be large, in order to avoid interference, it is recommended to use shielded control cables and ensure that the shield is well grounded.

Package Included:

* 1 x Solid State Microwave Generator

Packaging Details:

* Weight: 0.6kg