| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $202.82 | $198.68 | $192.47 | $184.19 | Contact US |

DM40B Standard Version 10Hz-50MHz Portable Digital Multimeter Oscilloscope Signal Generator with Magnetic PVC Sleeve

$124.94

DM40B Standard Version 10Hz-50MHz Portable Digital Multimeter Oscilloscope Signal Generator with Magnetic PVC Sleeve

$124.94

QDB-5A DC9-26V 100W Automobile Actuator Drive Detector Stepper Motor Ignition Coil PWM Signal Drive Tester

$43.17

QDB-5A DC9-26V 100W Automobile Actuator Drive Detector Stepper Motor Ignition Coil PWM Signal Drive Tester

$43.17

QDB-4A Automotive Ignition Coil Tester Injector Solenoid Valve Idling Stepper Motor Instrument Fault Detector

$59.69

QDB-4A Automotive Ignition Coil Tester Injector Solenoid Valve Idling Stepper Motor Instrument Fault Detector

$59.69

NI-210 Professional VI Curve Tester Circuit Board Tester Tool With Two-Channel Simultaneous Display

Attention:

It needs to be used with an oscilloscope, and there is no high requirement on the oscilloscope, as long as it is a dual trace oscilloscope. Both analog and digital oscilloscopes can be used (low-end digital oscilloscope xy mode display effect and response speed are a bit worse).

Features:

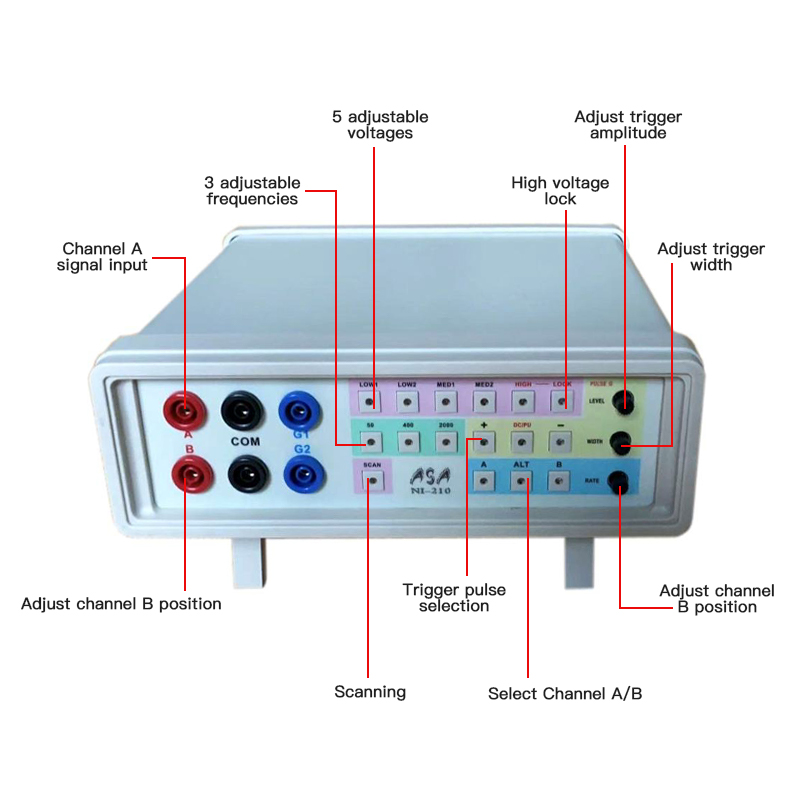

- Dual-channel signal input

- Two channels display 3 frequencies at the same time

- 5 adjustable voltages: 3V, 10V, 15V, 20V and 60V

- Channel A, channel B, channel A+B display

- With scanning function

- Adjust the position of channel B for easy comparison and measurement

- AC/DC trigger output with adjustable amplitude and width

Summary of the VI Tester:

1. ASA test application characteristics:

Analog Signature Analysis is a fault detection technique widely used in electronic circuit boards. Has the following application characteristics:

1.1. It does not involve the circuit principle and does not need the circuit to be in working condition, so it can be used for fault detection of the circuit board without drawings and data, which is out of the equipment (without online testing).

1.2. There is no need to power up the circuit board, which is relatively safer.

1.3. It does not involve the function of the components on the circuit board, so no matter what type of device the circuit is composed of, digital, analog, mixed digital-analog, known functions, unknown (such as dedicated, programmable), etc. can be tested.

1.4. It is tested on a circuit-by-circuit node (device pin), and is basically not limited by the packaging of components on the circuit board. Since a single device can be regarded as the simplest circuit board circuit, ASA technology can also be used to detect the quality of large-scale, complex or integrated devices with unknown functions. In fact, due to limited conditions, ASA is the only way for many users to detect such devices. In addition, when ASA is used to detect the function of discrete components, it is also convenient and intuitive.

2. The basic test principle of ASA:

As far as the basic detection principle is concerned, the ASA test can be seen as a natural extension of the multimeter detection method.

For circuit boards without drawings, the most commonly used fault detection method is as follows: first use a multimeter to measure the resistance of the device pins on the circuit board (actually the circuit node) to ground; and then compare it with the corresponding device pins on the failed circuit board. Compare the ground resistance, and judge whether there is a fault on the node according to the difference. From node to specific components need to be manually determined. This method is simple, easy to use and effective. Many people have used this method to repair complex and expensive circuit boards.

The main reason for the failure detection rate of this method is that the multimeter can only detect the resistance under 1.5V (multimeter battery voltage), and the ground resistance of the semiconductor device pin changes with the voltage-the resistance under different voltages may not be same. For example, a TTL device pin has a soft breakdown at 2.5V, resulting in a large leakage current. Such failures cannot be detected.

Imagine you have dozens or hundreds of multimeters, and the battery voltage of each meter is different-the voltage range includes the working voltage of the device. For each pin, use these tables to test and compare all of them, so that the above-mentioned faults will be detected. This is the principle of ASA testing—comparison in a voltage range, not just at a voltage point.

Package Included:

- 1 x Set of IV Curve Tester

Note:

- Battery is not included.