| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $113.92 | $111.59 | $108.10 | $103.45 | Contact US |

SO-ARM101 LeRobot 6DOF Robot Arm Robotic Arm Set (Assembled Dual-Camera Version with Standard Torque)

$537.81

SO-ARM101 LeRobot 6DOF Robot Arm Robotic Arm Set (Assembled Dual-Camera Version with Standard Torque)

$537.81

SO-ARM101 LeRobot 6DOF Robot Arm Robotic Arm Set (Assembled Basic Version with Standard Torque)

$471.22

SO-ARM101 LeRobot 6DOF Robot Arm Robotic Arm Set (Assembled Basic Version with Standard Torque)

$471.22

LiDAR Mount LiDAR Mounting Bracket Cover (Black) for LIVOX MID-360 & RoboSense Airy LiDAR Sensors

$40.96

LiDAR Mount LiDAR Mounting Bracket Cover (Black) for LIVOX MID-360 & RoboSense Airy LiDAR Sensors

$40.96

ROBSTRIDE05 5.5N·m Integrated High Performance QDD Actuator Module Robot Arm Joint Motor with CAN to USB Debugging Module

Description:

- Integrated design: motor, reducer, and driver are 3 in 1, with a peak torque of 5.5 N.m and weight of only 190g.

- Excellent performance: It has high-performance electronic control and closed-loop temperature control algorithms.

- Easy development: provides debugging software and mass production ability.

Applications:

- Robotics: suitable for joints of quadruped robots and humanoid robots, joints of robotic arms, and drive units of AMR and AGV, etc.

- Consumer products: suitable for power steering units of electric vehicles and scooters, Ebike power assist units, exoskeleton joints, lawn mowing robots, swimming pool cleaning robots, etc.

- Automation control: suitable for automated production equipment, automated mobile equipment, automated gates, etc.

Mechanical Specifications:

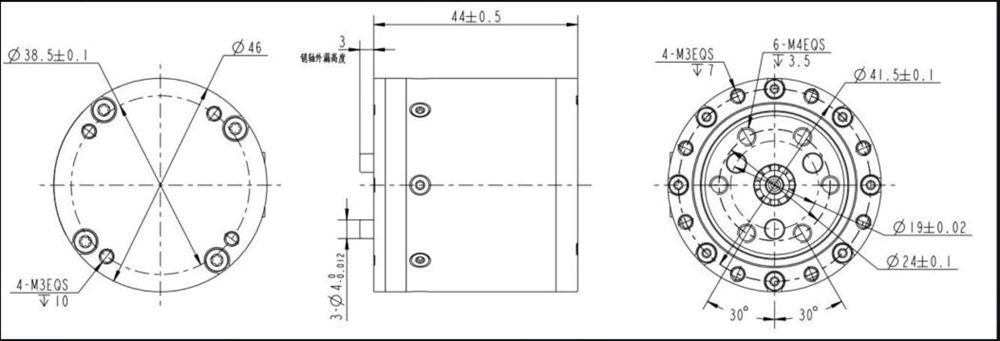

- Size: 46 x 46 x 44 mm

- Weight: 191g ± 10g

- Poles: 20

- Phases: 3 phases

- Drive method: FOC

- Reduction Ratio: 7.75 : 1

Standard Using Status:

- Rated voltage: 48V

- Voltage range: 15 - 60V

- Rated load (CW): 1.6 N.m

- Running direction: CW/CCW

- Using temperature: 25±5℃

- Temperature range: -20~50℃

- Storage temperature range: -30~70℃

- Using humidity: 65%

- Humidity range: 5~85%

- Insulation level: Class B

Electrical Specification:

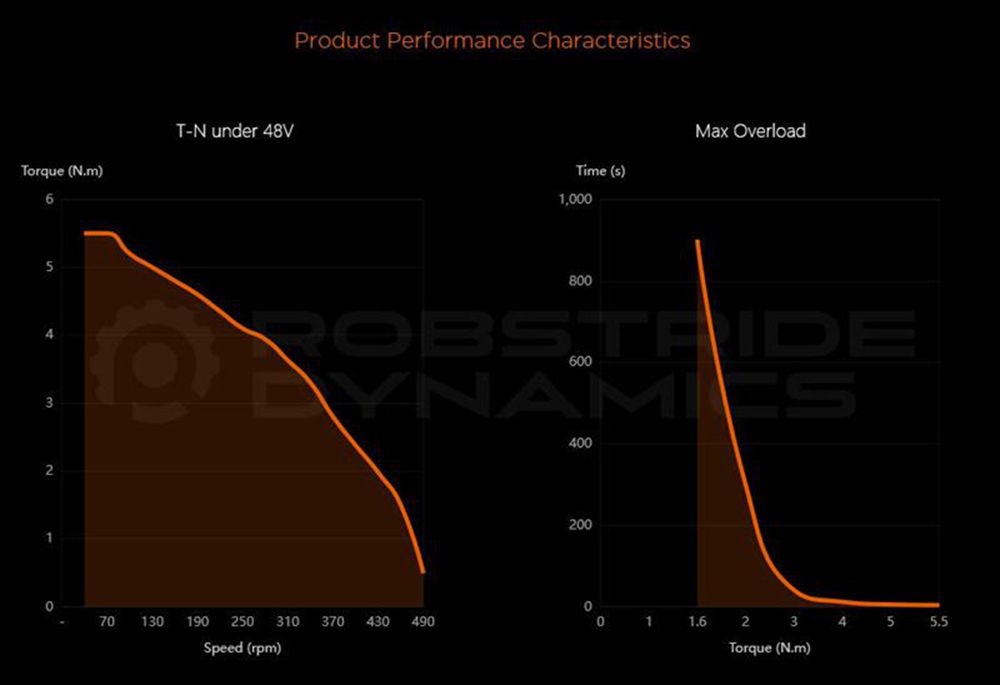

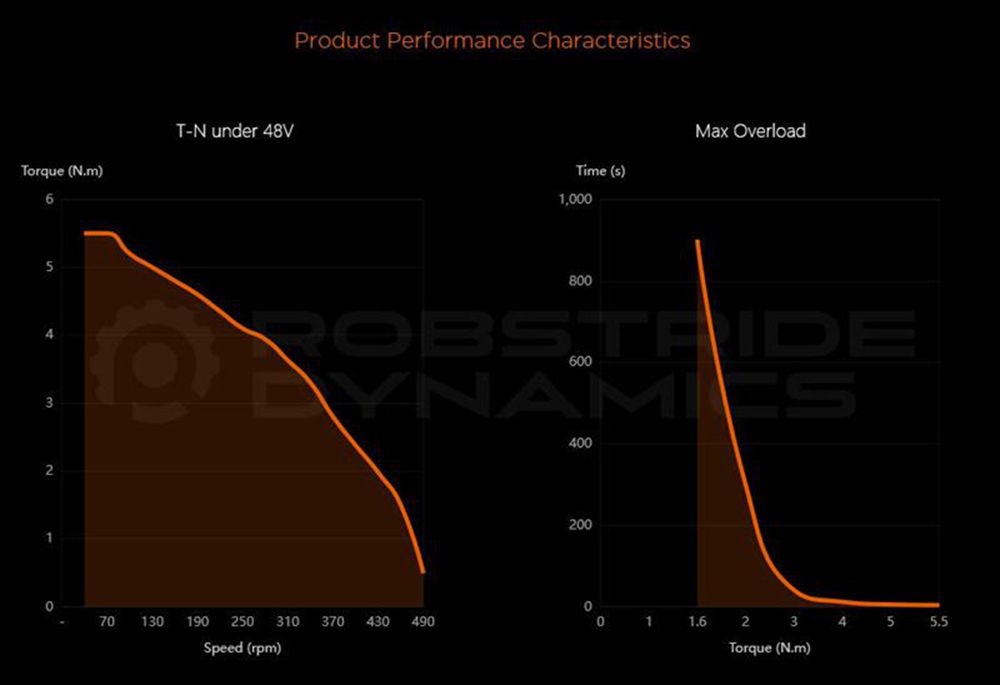

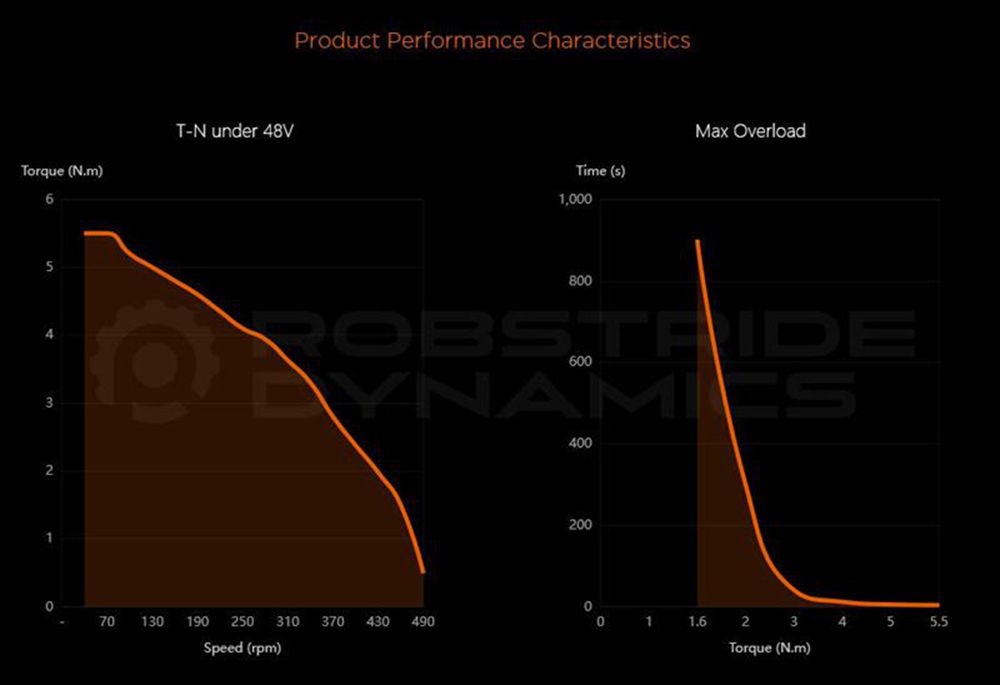

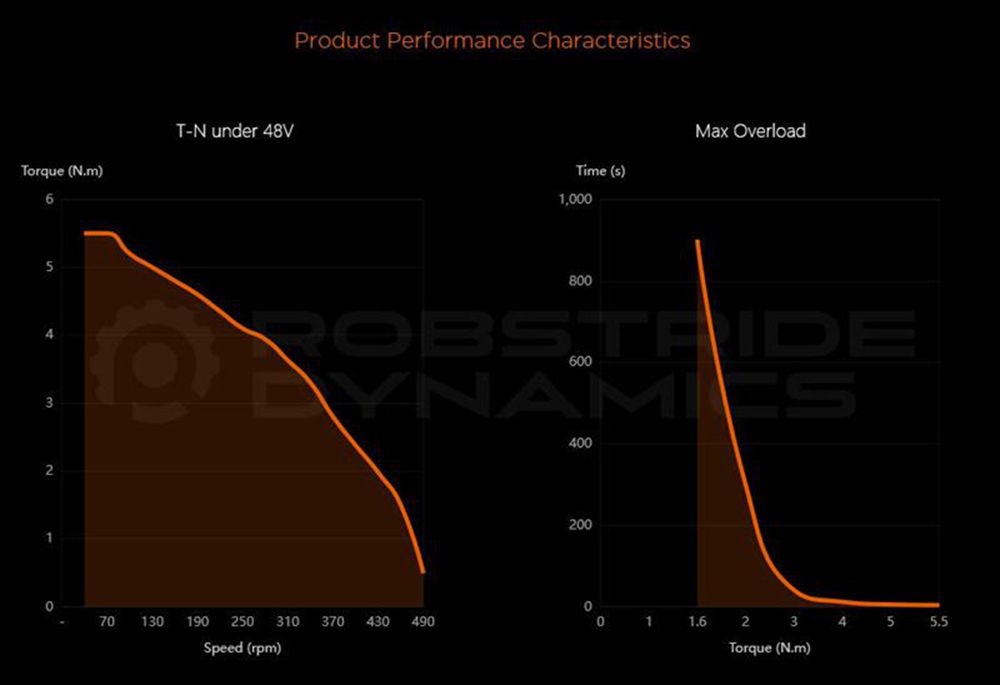

- No-load speed: 480rpm±10%

- No-load current: 0.14 Arms

- Rated load: 1.6N.m

- Rated load speed: 100rpm±10%

- Rated load phase current (peak): 2.4Apk±10%

- Peak load: 5.5 N.m

- Max load phase current (peak): 11Apk±10%

- Insulation resistance / stator winding: DC 500VAC, 100M 0hms

- High voltage resistance / stator and casing: 600 VAC, 1s, 2mA

- Back-EMF: 7.4 Vrms/kRPM±10%

- Torque constant: 0.94 N.m/Arms

- CAN bus baud rate: 1Mbps

- Encoder resolution: 14bit (single absolute)

- Encoder type: magnetic encoder

- Encoder number: 2

- Wire design: single port wiring

Compliance Certification:

- CE: FCC

CAN to USB Debugging Module:

- Bidirectional data conversion: collecting CAN bus data through USB and transmitting it to a computer for CAN bus network transmission and reception control, data analysis, and collection; Facilitating the sending of CAN commands between the PC serial port host computer and application programs to control devices such as motors.

- AT command mode: compatible with multiple brands of motors, convenient for controlling motors and OTA upgrades, monitoring, etc. through PC software.

- Core chip: The driver chip is CH340, the main chip adopts for GD series, and the serial port high baud rate transmission is 921600.

Package Included:

- 1 x Motor

- 1 x CAN to USB Debugging Module