| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $169.43 | $165.97 | $160.79 | $153.87 | Contact US |

Double-layer 42 Stepper Motor Intelligent Robot Car Chassis 4WD Chassis with 80mm Mecanum Wheels

$90.07

Double-layer 42 Stepper Motor Intelligent Robot Car Chassis 4WD Chassis with 80mm Mecanum Wheels

$90.07

Single-layer 42 Stepper Motor Intelligent Robot Car Chassis 4WD Chassis with 80mm Mecanum Wheels

$85.18

Single-layer 42 Stepper Motor Intelligent Robot Car Chassis 4WD Chassis with 80mm Mecanum Wheels

$85.18

Double-layer 42 Stepper Motor Intelligent Robot Car Chassis 4WD Chassis with 60mm Mecanum Wheels

$85.73

Double-layer 42 Stepper Motor Intelligent Robot Car Chassis 4WD Chassis with 60mm Mecanum Wheels

$85.73

SHDmini-08 Mini Horizontal Harmonic Reducer SHD-08 Harmonic Drive (100:1 Gear Ratio) for Robot Joint

Features:

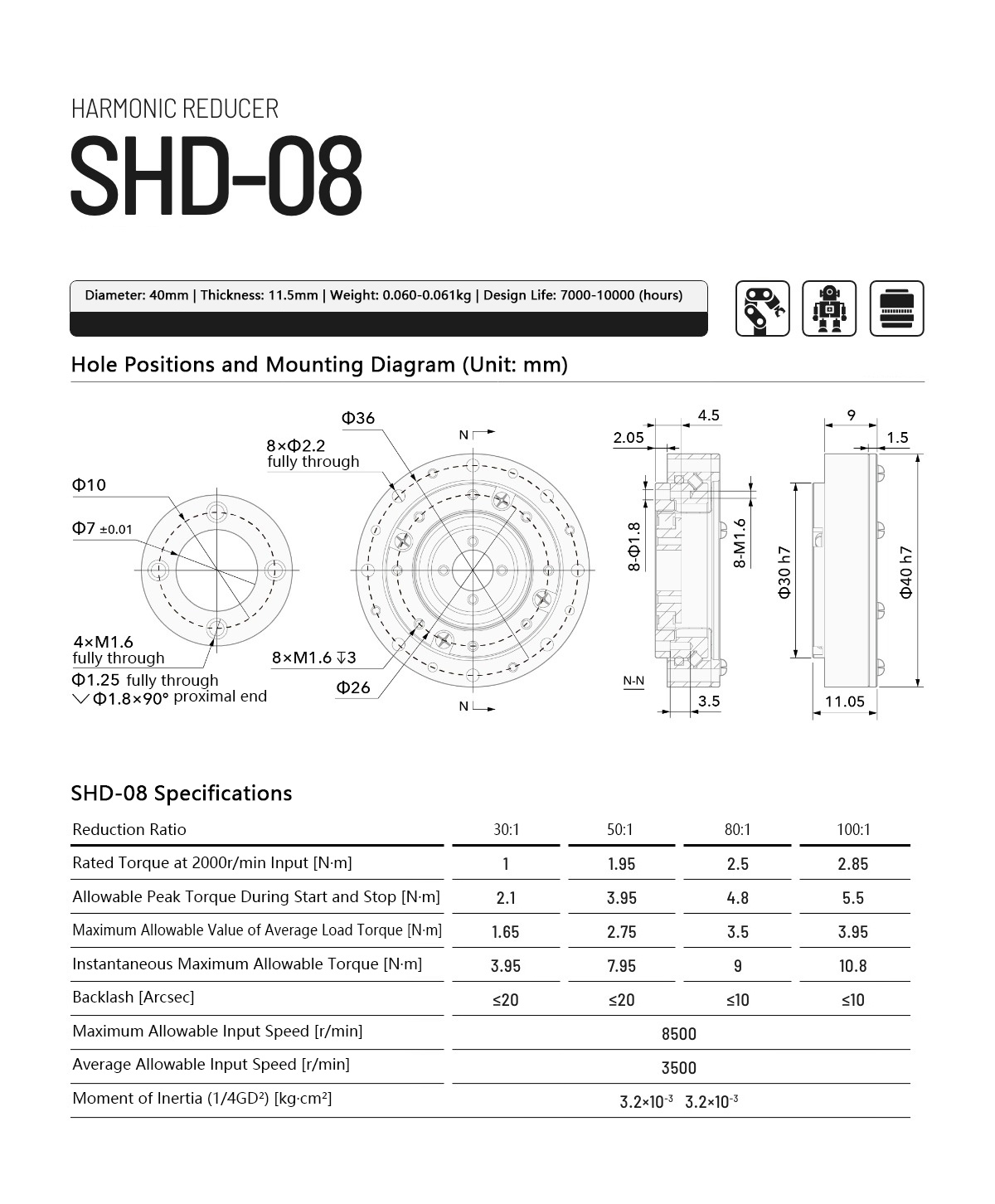

HD-08 Harmonic Reducer

* Diameter: 40mm

* Thickness: 11.5mm

* Weight: 0.060-0.061kg

* Design Life: 7000-10000 (hours)

* Precision-machined, long lifespan, more durable, and widely applicable

* Specially designed for robotic joints

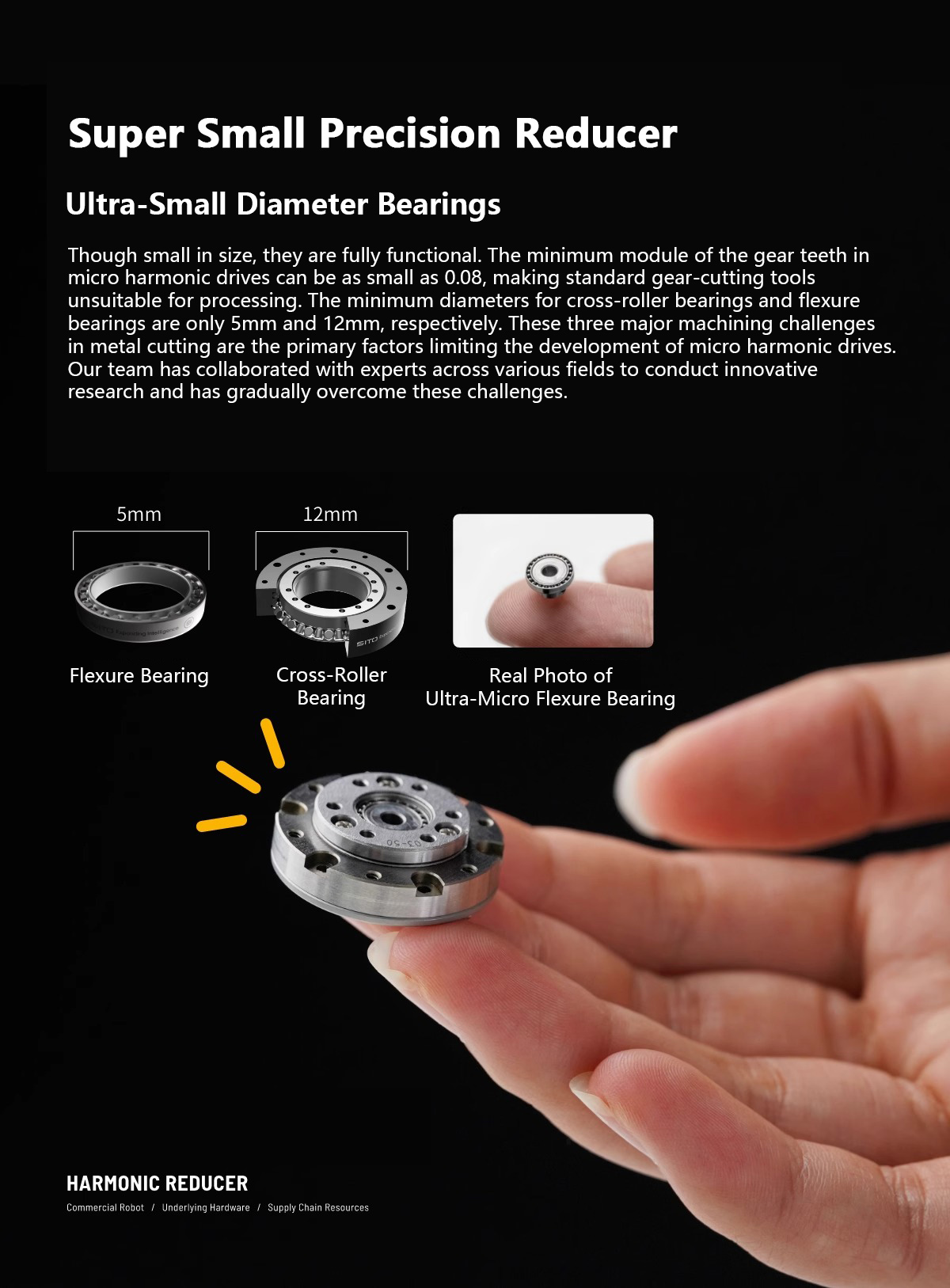

Super Small Precision Reducer

*

Ultra-Small Diameter Bearings: Though small in size, they are fully

functional. The minimum module of the gear teeth in micro harmonic

drives can be as small as 0.08, making standard gear-cutting tools

unsuitable for processing. The minimum diameters for cross-roller

bearings and flexure bearings are only 5mm and 12mm, respectively. These

three major machining challenges in metal cutting are the primary

factors limiting the development of micro harmonic drives. Our team has

collaborated with experts across various fields to conduct innovative

research and has gradually overcome these challenges.

Toughness Protection

*

By applying special electroslag remelting purification and repeated

rotary forging on raw materials with precise methods, we have improved

the stability of various performance indicators of the flexspline

material. This ensures the stringent requirements of the flexspline's

fatigue strength. Under overload conditions, the material's toughness

deformation maximally protects the entire mechanical structure from

damage.

Ultra-Fine Dense ADI Material

* We produce ultra-fine

dense ADI (Austempered Ductile Iron) material by using hollow continuous

casting spherical iron profiles followed by isothermal quenching. Its

features include:

1. Self-lubricating

2. Low temperature rise

3. Shock absorption and noise reduction

4. Wide operating temperature range

5. Long service life

Ultra-Precision Heat Treatment Process

*

After years of technical accumulation in material heat treatment, we

have identified the balance change law between hardness and toughness —

two factors affecting fatigue strength of harmonic drives. By combining

stress concentration after machining and stress relief before machining,

we formulated a complete heat treatment process which has been fully

implemented in mass production.

Special Flexspline Processing Technology

*

We invented a post-deformation finishing machining method for

flexspline tooth profiles. Under the premise of ensuring precision, this

method solves the problem of uneven contact in traditional steel

flexsplines, enabling fuller tooth surface engagement, more uniform

force distribution, reduced friction, and enhanced product durability.

Innovative S-Tooth Profile Design

*

In collaboration with the Deep-Sea Silent Transmission Laboratory of a

leading university, we conducted research on smoothing friction

transmission and reducing tooth-cutting friction coefficients, leading

to the invention of the S-shaped harmonic tooth profile theory. By

integrating kinematics, tribology, and lubrication science, we developed

simulation software capable of automatically generating S-shaped

curves.

Independent Tool Design and Development

* We

creatively developed an integrated composite tool combining front

cutting and rear pressing for harmonic gear processing. This

breakthrough overcomes the market gap caused by the manufacturing

difficulties of tools for micro harmonic reducers, resulting in a

uniquely industry-leading series of micro harmonic reducer products.

Harmonic Drive Testing Laboratory

*

We have partnered with universities and government quality inspection

bureaus to establish China's first comprehensive performance testing

platform for harmonic reducers. This platform covers lifetime, accuracy,

starting torque, torsional stiffness, load capacity, and other aspects,

providing comprehensive quality assurance throughout the harmonic

product development process and solid experimental data for all

development stages.

Ultra-Micro Cross-Roller Bearings

* The

production of miniature cross-roller bearings differs from conventional

models. Our research and design of an embedded separated channel

structure perfectly addresses the current market gap in ultra-small

raceway grinding machines. Through structural design, we have

technically and procedurally solved the challenges of ultra-small

processing in channel grinding machines.

Ultra-Micro Flexure Bearings

*

The manufacturing process of miniature flexure bearings, due to their

small outer diameter and thin structure, cannot follow the conventional

segmented processing methods used for standard bearings. To minimize

dimensional chain errors and deformation caused by multiple clamping

steps, a composite processing method is required that produces finished

products in a single setup.

* We have collaborated with the technical

team from a well-known Chinese bearing research institute to enhance a

small precision composite machining center by adding capabilities for

raceway grinding and laser heat treatment. This enables a one-stop

process flow—from turning → heat treatment → grinding → ultra-precision

raceway finishing—in a single setup, efficiently solving the

manufacturing challenges of ultra-small flexure bearings.

Packing List:

* 1 x Harmonic Gear Reducer

Packaging Details:

* Weight: 0.2kg

Note:

* Grease and adhesive are not included in the package.

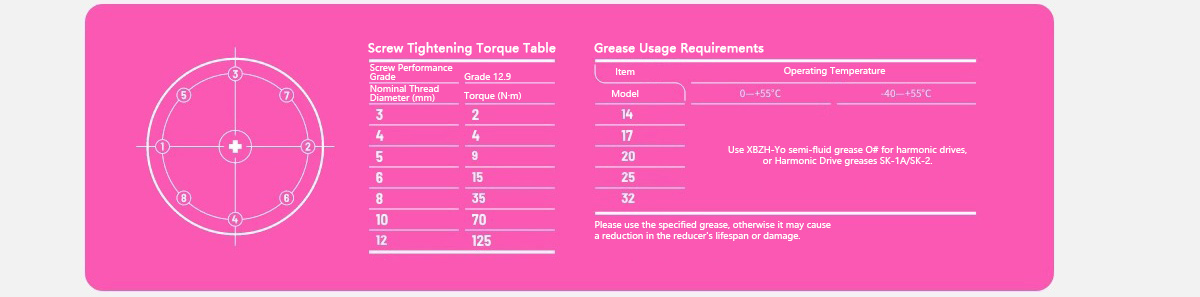

Reducer Installation and Precautions:

*

Inject grease into the inner wall space of the flexspline. Install the

reducer onto the output shaft, and fasten it with screws plus spring

washers for preload. The tightening sequence should be in a crosswise

(criss-cross) pattern, with a preload torque of 0.5N·m.

* Evenly

apply grease on the flexure bearing, then install the wave generator

into the bearings of the flexspline and output shaft. When installing

the wave generator, please pay special attention to keeping center

offset and tilt to a minimum to reduce the impact of eccentricity. Avoid

applying excessive force on the wave generator's bearing area; the wave

generator can be smoothly inserted by gently rotating it. After

installation, gently rotate the wave generator by hand. It is considered

normal if it rotates smoothly under average force. If there is

noticeable unevenness, it indicates asymmetric meshing; in this case,

remove and reinstall the wave generator.

* Apply Loctite 638 adhesive

to the key on the input shaft, then insert the shaft into the wave

generator. Use screws and spring washers to connect and preload the

input end to the reducer. The tightening sequence should follow a

crosswise (criss-cross) pattern, with a preload torque of 0.5N·m. Set

the motor speed to approximately 100RPM and start the motor. Tighten the

screws in a crosswise manner in four to five equal increments until the

screws reach their specified tightening torque (refer to the torque

values in the table). All screws used for connection and fastening must

be grade 12.9 and coated with thread locker to prevent loosening or

failure during operation.

* While keeping the motor rotating, tighten

the screws on the output end in a crosswise pattern, also in four to

five equal increments up to the specified tightening torque (refer to

the torque values in the table). Again, all fastening screws must be

grade 12.9 and coated with thread locker to avoid loosening or failure.

The recommended thread locker is Loctite 243.

Precautions:

1.

If the reducer's output end is always facing horizontally downward

during use, the grease injected into the inner wall space of the

flexspline must exceed the meshing tooth surface.

2. Static seals

must be applied between the mounting surfaces of the rigid spline and

its connecting parts, as well as between the flexspline and its

connecting parts, to ensure grease does not leak during reducer

operation and to prevent damage caused by insufficient or no

lubrication.

3. During installation, do not strike reducer parts with hard objects or apply excessive force to avoid part damage.

4. If you encounter any issues during installation, please contact us.