| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $137.10 | $134.30 | $130.11 | $124.51 | Contact US |

H2MD DC24-120V 6A Engraving Machine CNC Stepper Motor Driver Module Support Phase Dislocation Protection

$45.54

H2MD DC24-120V 6A Engraving Machine CNC Stepper Motor Driver Module Support Phase Dislocation Protection

$45.54

ZM-3H2080 24V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

ZM-3H2080 24V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

ZM-3H2080 12V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

ZM-3H2080 12V High Performance 3-Phase Stepper Motor Driver Controller AC80-220V for 86-130MM Stepper Motors

$166.32

CNC Very Professional 3 Axis 3.5A TB6560 Stepping Motor Driver Controller LCD Display CNC Router

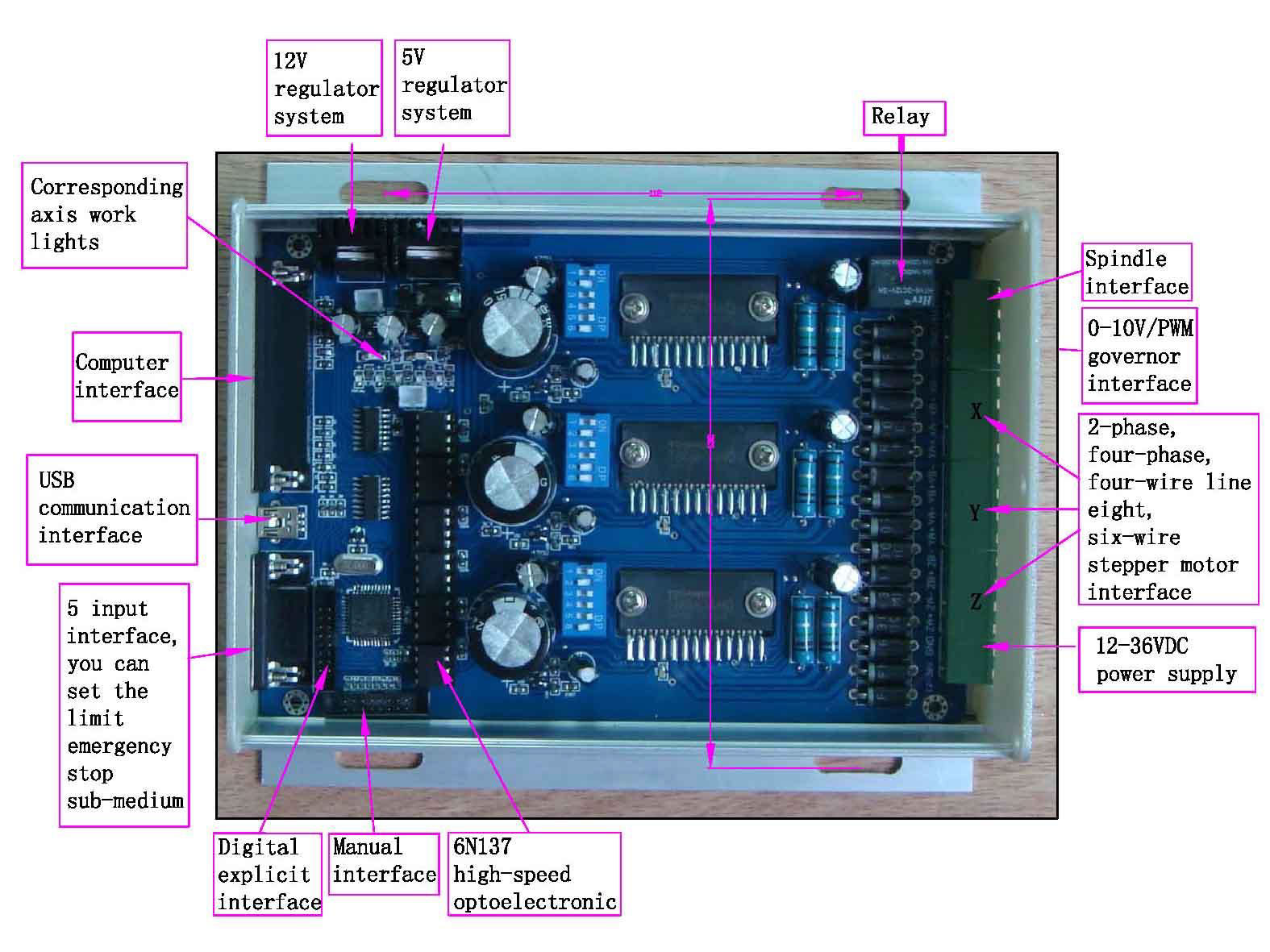

Features:

- High performance, cost-effective.

- Automatic idle-current reduction.

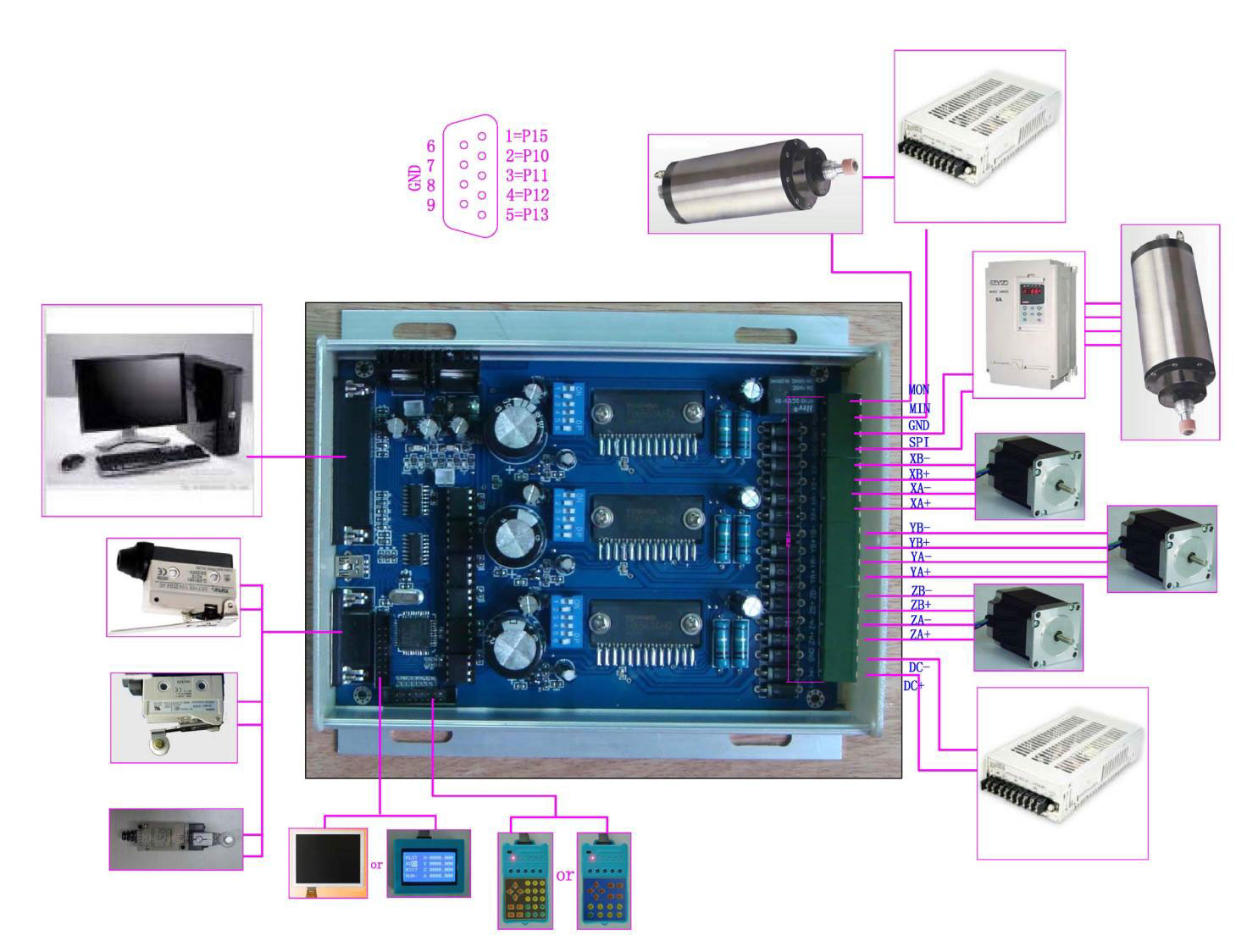

- To manually control the stepper motor, both of the standard and professional drivers have been equipped with the display panel and control pad.

- Automatically identify both of the computer and control pad, functions of the computer and control pad can be switched intelligently for each other without any interference.

- Display panel can real-time trail the running path of G-Code on the computer or input by the control pad, and then completely and Simultaneous display the changing of each axis'(X, Y, Z axis etc.) values on its screen.

- Both of the standard version and professional version are compatible with the Mach2, Mach3(Default Software), LinuxCNC(EMC2), KCAM4 CNC Software, etc.. Besides, the professional version also can automatically trail the path running path of G-Code from the CNC software (e.g. Mach3, EMC2, KCAM4, etc.) of the computer and record the G-code into the memory chip; Easy to repeatedly run the G-code to control the stepper motors without computer.

- The professional version also support manual programming via the control pad, as long as input the required values on one axis and record them in the memory chip of the driver, and then run these recorded values to drive the axis to make linear motion, widely used on RBI machine, Conveyor and so on.

- Automatically finish Tool-settings on X, Y, Z Axis via the control pad, without the support of the computer.

- Compatible with all the motors with 0.5A-3.5A (peak) rated current, four types of adjustable output current can be set on the driver board.

- 1, 2, 8, 16 adjustable microstep control, motors run more precisely and smoothly.

- Overload, overcurrent, overvoltage, overheat protection to avoid damaging your computer and devices.

- Totally enclosed optical isolation and bipolar constant-current chopper to insure motors work at low noise & vibration, and avoid motors creep at a low speed.

- With one 0-10V PWM Signal output port for speed adjustment and one Relay control port.

- 5 types of input control in manual control interface, to set Limit, Estop, Midpoint-Setting, Cutter-presetting/Tool-Setting etc..

- Cooling Aluminium Box Design for Cooling, and protect the driver board from being damaged by dirt, dust or other liquids.

Applications:

- For processing various pattern mould.

- For advising, such as brand, architechture mould, badge, nameplate, display boards, doorplate, furniture decoration, etc..

- For carving portrait, scenery, handwriting, sealing, etc..

- Suitable for any small-and-medium automatic equipment with CNC controller, such as X-Y-Z tables, labeling machines, laser cutters, engraving machines, and pick-place devices.

Further:

- DC 12-36V power supply selection

*Voltage Selection:

12-16V DC power supply for Nema 17 stepper motors

16-24V DC power supply for Nema 23 stepper motors

24-36V DC power supply for Nema 34 stepper motors

(High voltage will burn out the chips or stepper motors!!!)

*Current Selection:

- Output current of the power supply can be calculated by the following formula:

- Output current = Rated current of your stepper motors * quantity + 2A

(For example, if you want to drive 3 * 2A Nema 23 stepper motors, theoretically 24V 8A DC power supply is recommended, but higher power such as 24V 10A/15A also will be good.

- If you are not sure about the selection of power supply, please feel free to contact us for help)

- Please SHUT DOWN the power before you plug or unplug the connectors to avoid burning up the board.

Click here to download the manual !

Package list:

- 1 * Professional 3 Axis TB6560 Stepper Driver

- 1 * Control Pad (Built-in)

- 1 * LCD Display Panel (Built-in)

- 1 * DB25 Parallel Cable

- 1 * CD Driver

- 5 * Terminal