| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $13.31 | $13.04 | $12.63 | $12.09 | Contact US |

XLT-802 Automatic Screw Feeder 1.0-5.0mm Screw Conveyor with Adjustable Guide Rail and Side Speed Adjustment Knob

$112.87

XLT-802 Automatic Screw Feeder 1.0-5.0mm Screw Conveyor with Adjustable Guide Rail and Side Speed Adjustment Knob

$112.87

HM-130HP Dual Action Airbrush 8-85PSI 0.3MM High Performance Quick Release Spray Nozzle Air Pressure Gun

$50.69

HM-130HP Dual Action Airbrush 8-85PSI 0.3MM High Performance Quick Release Spray Nozzle Air Pressure Gun

$50.69

T90C (T65 Tip) Portable Intelligent Soldering Iron IPS LCD Screen 18-130W Soldering Pen with PD 140W Adapter and T65-KU/BC2 Tips

$82.62

T90C (T65 Tip) Portable Intelligent Soldering Iron IPS LCD Screen 18-130W Soldering Pen with PD 140W Adapter and T65-KU/BC2 Tips

$82.62

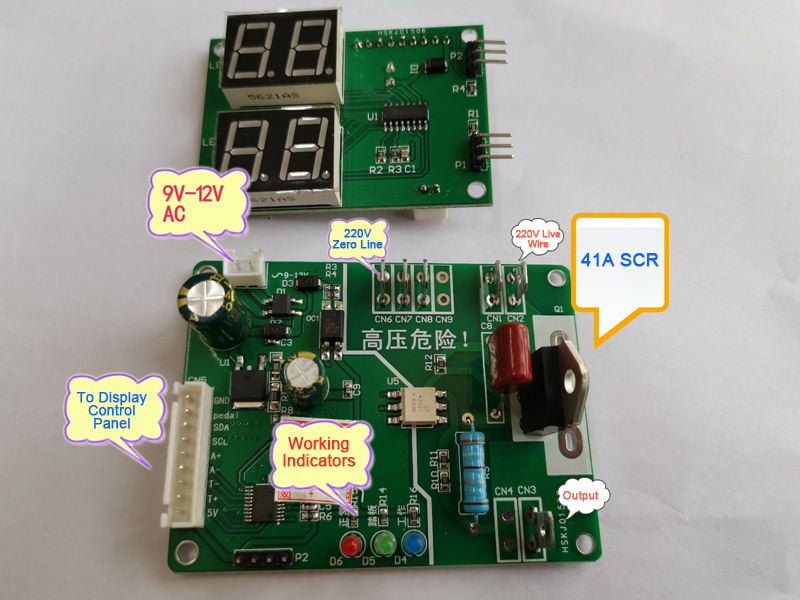

DIY Spot Welding Controller Kit Spot Welder Control Board Time & Current Digital Tubes w/ 41A SCR

Description:

1. Spot Welder Control Board:

- Function introduction: Control the precise time of 220V load AC power on, accurate to milliseconds. MCU controls pulse signal and adjusts thyristor pulse to adjust output power.

- Power range: Control output via 41A SCR

2. Requirements for matching transformer: 9-12v AC transformer 150mA

3. SCR can control dual transformers: The board is designed with an adapter socket, and dual transformers can be connected at the same time. You need to purchase an additional 100A SCR.

4. Use Range:

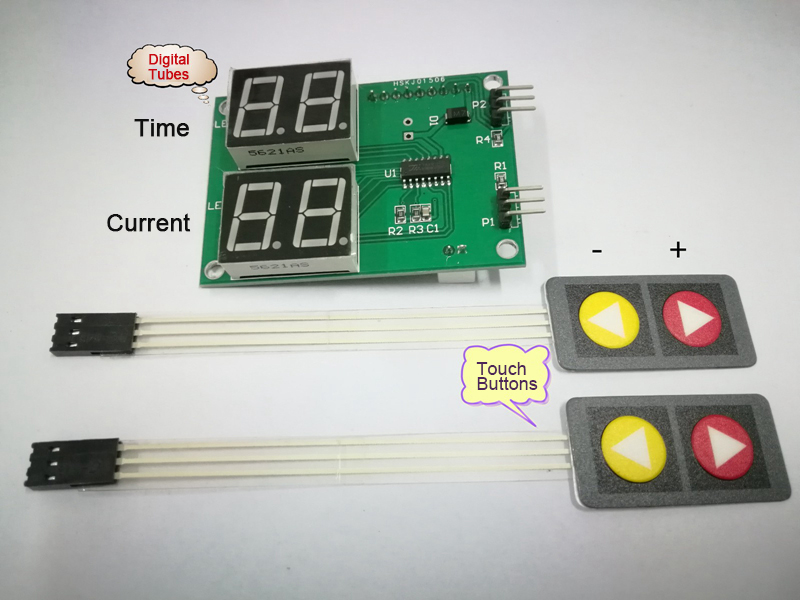

- Time displayed on upper digital tube: Adjust through the corresponding two touch buttons. Each additional number represents an increase of 20 milliseconds. 01 means an increase of 20 milliseconds, and 02 means an increase of 40 milliseconds.

- Power (current) displayed on lower digital tube: Adjust through the corresponding two touch buttons. You can press and hold to quickly jump the value. 99 is the maximum power, and the value is designed to decrease in percentage, for example, if it is adjusted to 50, the output power is half.

Detailed Introduction:

1. Time & Current: millisecond level control. When the control panel displays 01, it is a cycle of 20 milliseconds. 01-10 increase sequentially, and the longest time is 200 milliseconds.

2. Current Power: The main purpose of controlling current power is to control the time cutting angle of signals and adjust the degree of conduction in each cycle to adjust output power.

3. Spot Welding Machine Time & Current Adjustment: Take water pipe running as an example, turn on a water pipe and turn it off after 10 seconds, it takes 10 seconds totally. When the water pipe is screwed to the maximum water output and half of the water output, the amount of water flowing out in relative time is different. This is to control the water flow, which is similar to current controlled by control panel.

4. Power-Off Save: After the control board adjusts parameters, the welding parameters will be automatically saved when power supply is suddenly cut off during the welding process. After starting the machine next time, you don't need to re-debug it, you can use it directly. The data will be automatically saved when shutting down normally.

Control Panel Parameters:

- Power supply: Greater than AC9-12V, 150Ma, 50HZ/60HZ AC power supply

- Starting method: Pedal or other passive normally open point. Note that it must be a normally open point

- Display form: 56 digital tube

- Adjustment method: touch buttons

- Time range: 1-10

- Current range: 30-99 which can be adjusted quickly by long pressing

- Welding output: single pulse

- Save when power off: Yes

- Trigger form: imported optocoupler for SCR

Multiple Protections:

1. The control board is designed with hot ground and cold ground circuits. Pay attention to electric shock, and your hands can touch the pedal line. There is no danger of electric shock from pedal cable, display module and small signal control part.

2. Pedal is a single trigger. It can be triggered again after releasing the pedal. There is no requirement for the time interval between two triggers.

3. The board SCR high current place is tinned to ensure the normal use of high current.

4. The driver board is compatible with 41A and 100A SCRs. Boards delivered are designed with a 41A SCRs, which can only be used on a single microwave oven transformer. If you need to connect two transformers, the 41A SCR needs to be removed and replaced with a 100A SCR.

5. Pay attention to heat dissipation. SCR, like ordinary transistors, is greatly affected by temperature. If the temperature is too high, it will easily cause malfunctions and even burn the device. If the power is relatively large, a radiator should be installed during installation.

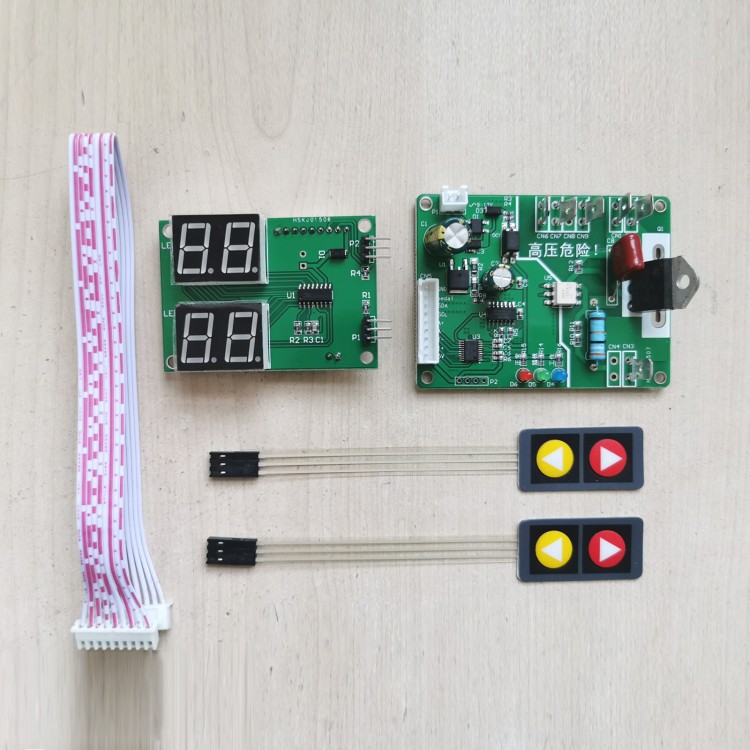

Package Included:

- 1 x Set of Spot Welder Control Board