| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $205.49 | $201.29 | $195.00 | $186.62 | Contact US |

FUZRR ES3000P Multifunctional Micro-controller 3-Wire Ground Resistance Tester 0-20Kohms High Precision Earth Resistance Tester

$275.47

FUZRR ES3000P Multifunctional Micro-controller 3-Wire Ground Resistance Tester 0-20Kohms High Precision Earth Resistance Tester

$275.47

150W Multifunctional Bluetooth Battery Capacity Tester CC/CR/CP/CV/PT/BRT Intelligent DC Programmable Electronic Load

$59.21

150W Multifunctional Bluetooth Battery Capacity Tester CC/CR/CP/CV/PT/BRT Intelligent DC Programmable Electronic Load

$59.21

FUZRR ES3090E 220A Loop Resistance Tester Micro-ohmmeter for High Voltage Switch Contact Resistance Measurement

$1,466.23

FUZRR ES3090E 220A Loop Resistance Tester Micro-ohmmeter for High Voltage Switch Contact Resistance Measurement

$1,466.23

LCDA808H 2 Phase Nema34 Stepper Driver + LC86H280 86 Nema34 Closed Loop Hybrid Digital Servo Motor

Product Description:

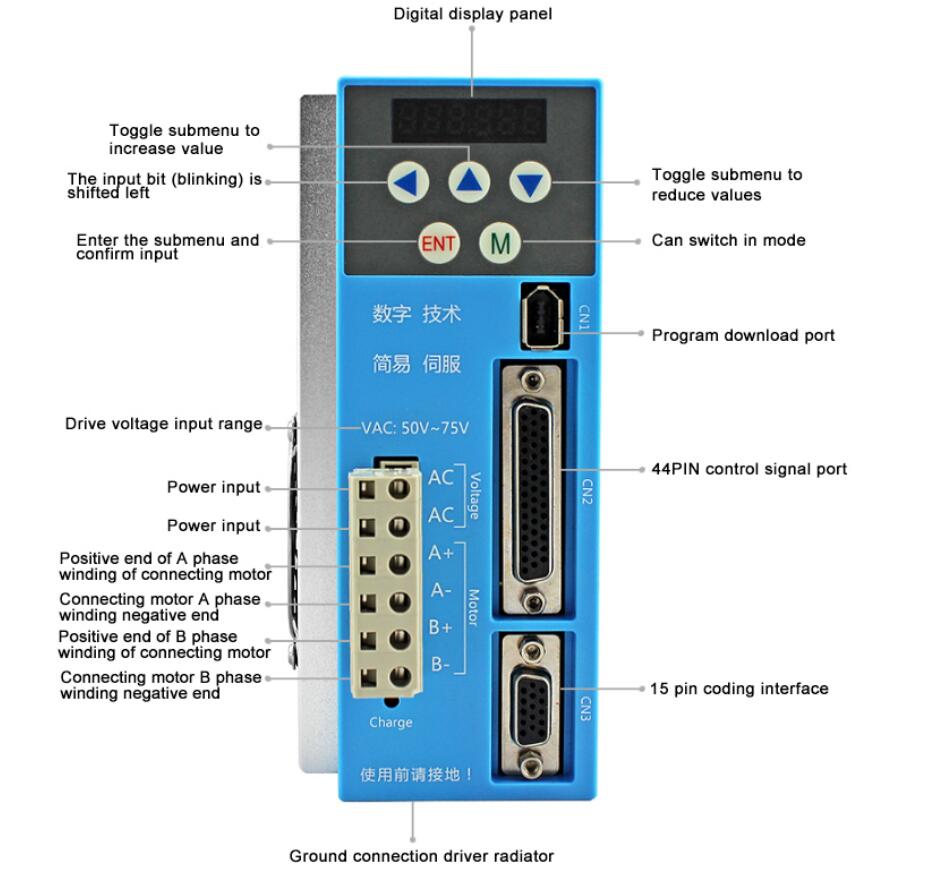

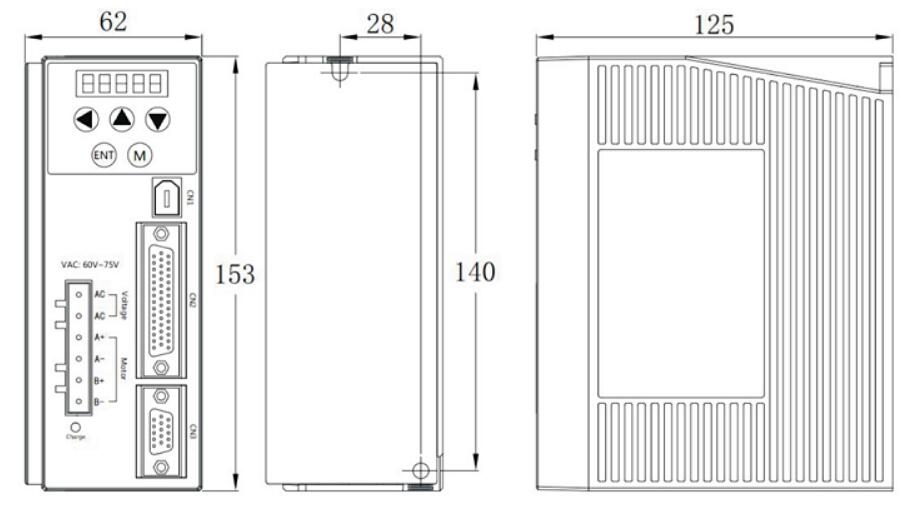

- Product Name:LCDA808H 2 Phase Nema34 stepper digital servo driver

- LCDA808H (LC86H280 Motor) using the latest dedicated motor control DSP chip and vector closed-loop control technology, completely overcome the open-loop stepper motor lost step problems, while significantly enhance the motor high-speed performance, reduce motor heating and reduce motor vibration, improve machine processing speed and accuracy, Machine energy consumption. This drive is suitable for motor mounting size is fully compatible with 86 series stepper motor to facilitate the traditional step-by-step drive program upgrade, significantly reduce costs.

Features:

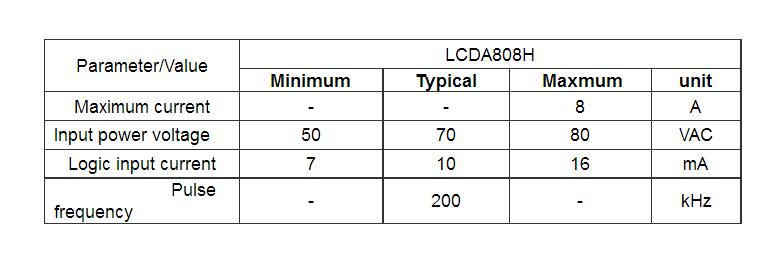

1. Voltage input range: 50V ~ 80VAC

2. Maximum peak current: 8A

3. Subdivision range: 200 ~ 51200ppr

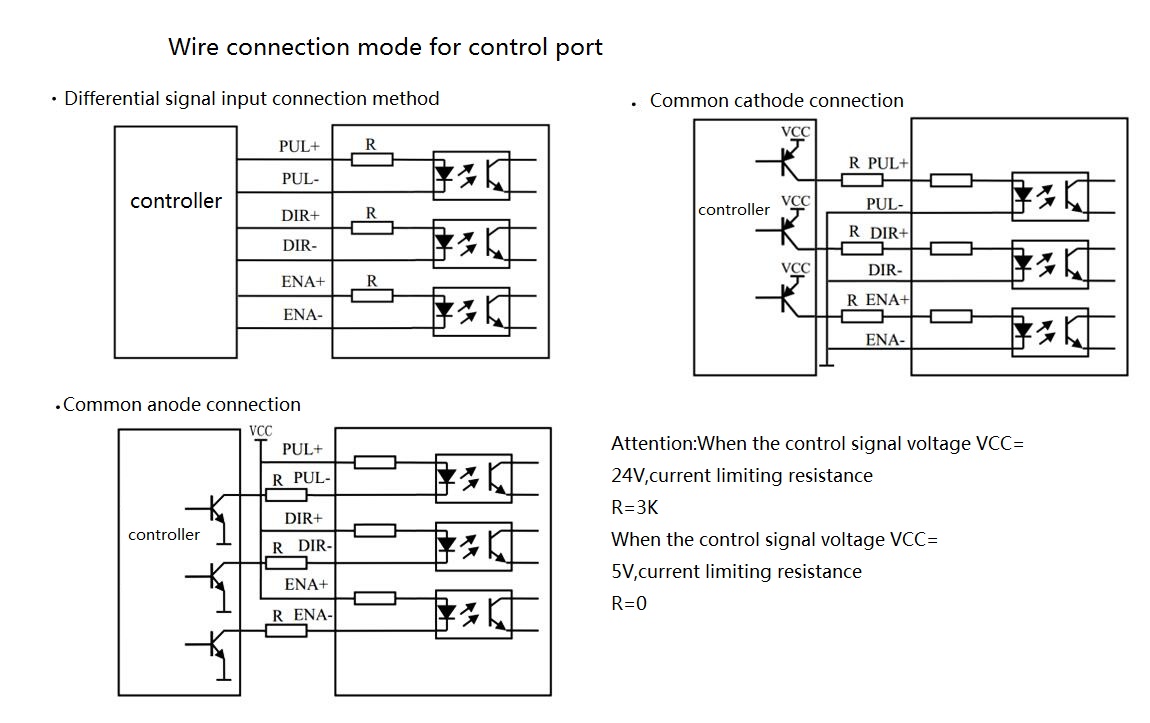

4. Signal input: differential / single-ended, pulse / direction

5. Impulse response maximum frequency: 200KHZ

6. External digital debugging panel for easy parameter setting and monitoring

7. Serial communication function, current, subdivision can be adjusted, signal edge, alarm output logic and other functions adjustable

8. Closed-loop vector control to ensure that the motor high-speed high-torque output,

While ensuring the motor does not lose step, with over-voltage, over-current, tracking error tolerance

Main parameters:

1. Electrical indicators

2.Interface definition

1) Motor & power input port

Symbol:A+

Name:A-phase motor winding positive terminal

Symbol:A-

Name:A phase motor winding negative terminal

Symbol:B+

Name:B-phase motor winding positive terminal

Symbol:B-

Name:B-phase motor winding negative terminal

Symbol:AC

Name:Power supply access terminal

Symbol:AC

Name:Power supply access terminal

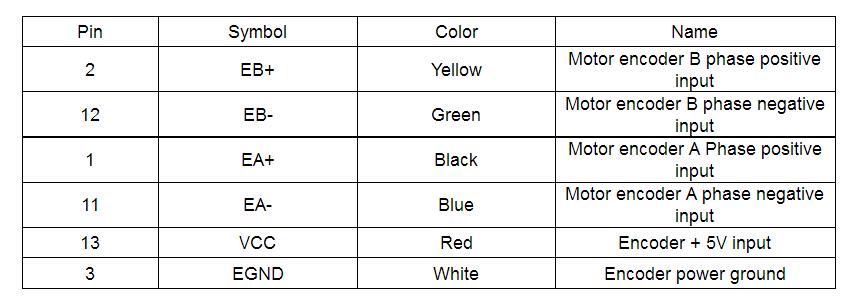

2)Driver encoder terminal definition (LCDA808H encoder signal terminal with 15Pin DP header, pin defined as follows :)

3) Control signal port

Name: PUL+

Explanation: Pulse input signal: pulse effective edge adjustable, the default pulse rising edge is valid; in order to reliably respond to the pulse signal, the pulse width should be greater than 1.2μs. Such as the use of +12 V or +24 V when the need to string 3K resistance

Name: PUL-

Pulse input signal: Pulse input signal: pulse effective edge adjustable, the default pulse rising edge is valid; in order to reliably respond to the pulse signal, the pulse width should be greater than 1.2μs. Such as the use of +12 V or +24 V when the need to string 3K resistance

Name: DIR+

Explanation: Direction input signal: high / low level signal, in order to ensure reliable reversing of the motor, the direction of the signal should be preceded by pulse signal at least 5μs to establish, such as the use of +12 V or +24 V string 3K resistor.

Name: DIR-

Explanation: Direction input signal: high / low level signal, in order to ensure reliable reversing of the motor, the direction of the signal should be preceded by pulse signal at least 5μs to establish, such as the use of +12 V or +24 V string 3K resistor.

Name: ENA+

Explanation: Enable control signal: This input signal is used to enable or disable. When ENA +, ENA- have input, the drive will cut off the motor phase to make the motor in a free state. When this function is not required, the terminal can be left floating.

Such as the use of +12 V or +24 V when the need to string 3K resistance

Name: ENA-

Explanation: Enable control signal: This input signal is used to enable or disable. When ENA +, ENA- have input, the drive will cut off the motor phase to make the motor in a free state. When this function is not required, the terminal can be left floating.

Such as the use of +12 V or +24 V when the need to string 3K resistance

Name: Pend+

Explanation: Positioning completion signal positive side

Name: Pend-

Explanation: Positioning completion signal negative

Name: ALM+

Explanation: Alarm output positive terminal

Name: ALM-

Explanation: Alarm output negative terminal

Application Areas:

Suitable for all kinds of small and medium-sized automation equipment and equipment, such as: engraving machine, stripping machine, marking machine, cutting machine, laser machine, medical equipment, CNC machine tools, automatic assembly equipment, electronic processing equipment. In the user expectations of low noise, high speed equipment in the application of special results.

Product download: Click here

Package List:

- 1 x 86 Nema34 Closed Loop Stepper Digital Servo

- 1 x LC86H280 Motor Driver