| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $129.01 | $126.37 | $122.43 | $117.16 | Contact US |

Hiwonder 6CH Bluetooth Servo Controller Bluetooth 4.0 for Robotic Arm, Biped Robot & PS2 Controller

$26.64

Hiwonder 6CH Bluetooth Servo Controller Bluetooth 4.0 for Robotic Arm, Biped Robot & PS2 Controller

$26.64

Hiwonder Universal Bus Servo Controller Board for PS2 Controller/Bluetooth Module/Robotic Arm/Robot

$28.58

Hiwonder Universal Bus Servo Controller Board for PS2 Controller/Bluetooth Module/Robotic Arm/Robot

$28.58

Hiwonder 6-Channel Servo Controller Board w/ Knobs & Over-Current Protection for Robot & Robotic Arm

$18.87

Hiwonder 6-Channel Servo Controller Board w/ Knobs & Over-Current Protection for Robot & Robotic Arm

$18.87

DDTS380 400KG.CM High Torque Servo Ideal UAV Precision Industrial Steering Servo Remote Control

Product Features:

* Applicable to servo controller, model airplane remote control

* Alloy gear high torque motor

* Aluminum alloy gearbox is ultra-lightweight

* Easy to install, durable, reliable, stable and practical

Application Range:

* Large robots, mechanical arm power joints

* Industrial robot automation

* Precise control of valve angle

* Large camera pan/tilt

* Large remote control car model, remote control ship model

Attention:

Please test various application scenarios by yourself, and use them after the test is qualified. Please use large-scale testing for various application scenarios by yourself. We are not responsible for the consequences of this!

Technical Parameters:

- Rated voltage: DC24V (12V-24V can work, 12V torque and speed are halved)

- No-load current: <500MA (load current 5-10A, it is recommended to use 10A or more than 10A switching power supply or battery, the greater the power supply current output capacity, the better. Battery is not included)

- Limit angle: 1200US-1700US: about 90 degrees. 500US-2500US: about 288 degrees (the pulse width determines the angle, if you need other angles, please increase or decrease the pulse width by yourself, the maximum is about 288 degrees)

- Control method: PWM pulse width modulation signal, frequency 50HZ, period 20MS. Signal voltage: 3.3V-5V. (Pulse frequency: 50-333HZ)

- Material: Gear and shaft: alloy steel, hardened steel, aluminum alloy; shell: aluminum alloy

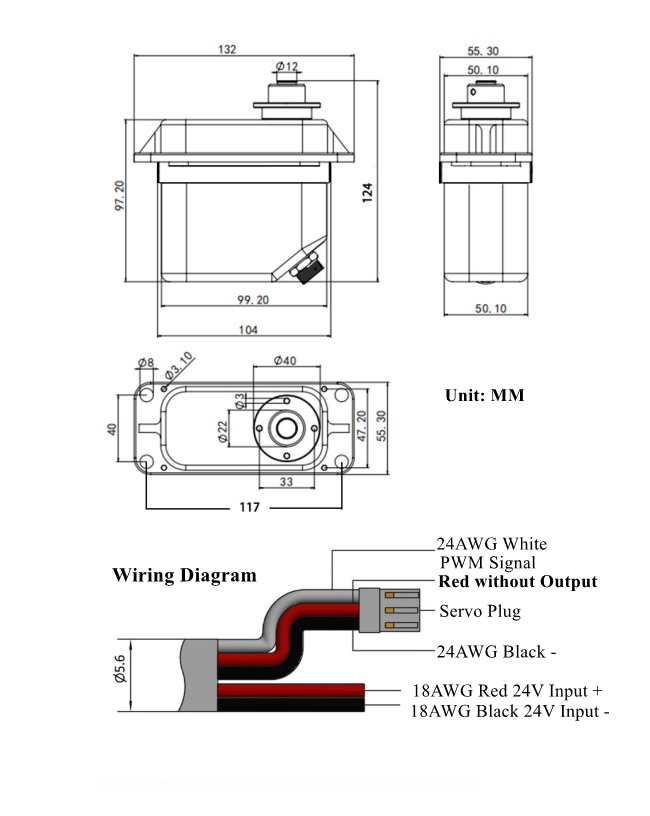

- Weight: about 880g

- Speed: 0.5S/60°(equivalent to 20RPM)

- Mechanical life: >300,000 times (370 hours)/(30KG/CM)

- Limit torque: 400KG/CM (tooth chipping load, it is not recommended to work at this torque)

- Starting torque: 380KG/CM (short-time work)

- Conventional torque: 140KG/CM (can work for a long time)

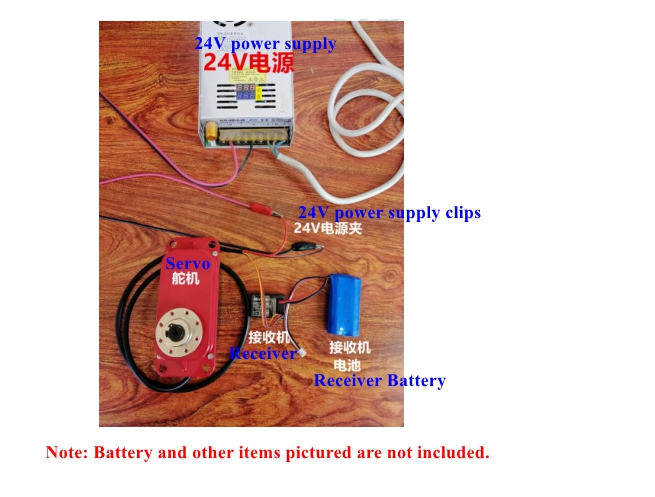

Package Included:

- 1 x Servo

Note:

- Battery and other items pictured are not included in the package, for demonstration purposes only. Thank you for your understanding!

Wiring Diagram (when using R/C receiver):

- The five lines are drawn from the DDTS380 servo.

- Three of the five wires: orange is the signal, red is the empty pin, and brown is the ground wire. Used to connect to the control signal of the receiver or servo controller. It can be directly connected to the receiver for FUTABA or JR.

- In addition, you must prepare a separate 24V power supply to drive the servo. The red wire is the positive pole and the black wire is the negative pole. Please note that our servo can work with 12V-24V voltage, but the lower the voltage, the slower the speed and the smaller the torque. The marked torque value and speed value are both the value of 24V power supply.

- If only power is supplied and no signal is input, the servo will not move and will not output torque!

- If you only supply power and remove the signal during use, the servo will not move and will not output torque!

- When powering on, please connect the signal first, and then supply power to the servo. When shutting down, please turn off the power first, and then turn off the signal! This is the normal operating procedure.