| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $371.69 | $364.11 | $352.73 | $337.56 | Contact US |

ANNOY TOOLS 3-Axis CNC Controller Board GRBL 1.1f with USB Cable for Offline Controller 500W Spindle

$34.79

ANNOY TOOLS 3-Axis CNC Controller Board GRBL 1.1f with USB Cable for Offline Controller 500W Spindle

$34.79

5pcs Top Suction Plates Rubber Suction Pad (125mmx75mmx17mm with Large Hole) for Vacuum Blocks

$39.60

5pcs Top Suction Plates Rubber Suction Pad (125mmx75mmx17mm with Large Hole) for Vacuum Blocks

$39.60

5pcs Top Suction Plates Rubber Suction Pad (125mmx75mmx17mm with Small Hole) for Vacuum Blocks

$39.60

5pcs Top Suction Plates Rubber Suction Pad (125mmx75mmx17mm with Small Hole) for Vacuum Blocks

$39.60

F2100B 2-Axis CNC Controller + F1510-T CNC Remote Control Plasma Cutting Controller w/ Receiver

Package Included:

- 1 x Set of CNC Controller + CNC Remote Control w/ Receiver

F2100B 2-Axis CNC Controller:

System Description:

- F2100B CNC system is in the company to absorb the advantages of many domestic and international CNC system, combined with the company F2100, F2200 and F2300, F3100, F5100 series CNC system, developed a more humane, more convenient, more cost-effective products. The product uses two axis digital position control mode, suitable for oxygen gas and plasma cutting processing industry. For two axis NC machine in all with position control method.

- The control system is light and portable, simple operation, easy to use, all the operation has a menu or graphical clues, operate a fool. Humanization design all the key switch, comfortable and convenient.

- By the special motor control chip DSP core control system, DSP control the motor so that the cutting process is more stable and reliable. DSP motion control algorithm for the optimization and upgrade in the original F2200, to make the machine run more smoothly and reliably, prolong the life of electrical and mechanical parts.

System Features:

- Chinese / English menu system, Chinese English French interface of one key switching.

- 45 kinds of commonly used graphics library (including the grid graphics), can choose the set piece size and pore size.

- Supports for EIA code (G code) and FastCAM, FreeNest, IBE, Wentai, PM2000 and other kinds of nesting software

- Compact keyboard type design, make more comprehensive manual input file

- Graphic proportion, rotation, mirror

- Graphics can be arranged in a matrix arrangement, interaction, stacked arrangement

- Workpiece with slotted size of original size and at the same time display, intuitive and convenient

- Graphic plate correction, arbitrary edges of plate can be used as a correction boundary

- Can customize the types of all input and output ports (normally closed or open) and number

- Self diagnostic system for all IO and key state, convenient examination and troubleshooting

- The pre U disk interface for convenient program transmission

- Using U disk upgrade system, which is convenient and simple, practical, lifetime free upgrades

- All functions can be upgraded online as a whole.

- Can import and export single or all processing files

Backup or Restore Parameters:

- Supporting oxygen gas, plasma, dusting and demonstrates modes

- All kinds of machining parameters are complete, which can meet different process requirements

- Oxygen gas and plasma IO separate control

- Oxygen gas automatic height adjustment, two stage preheating, three level perforation

- Plasma arc voltage feedback, position feedback, automatic closing high pressure arc angle

- Control supports the speed and distance of two shut down arc voltage mode l plasma arc pressure, make the machine more balanced, safe

- Supports edge-cutting, the preheating time can be reduced for thick steel board

- Acceleration, deceleration of speed during the motion.

- According to the thickness of the steel plate, speed will be automatically controlled in the corner, effectively preventing over-burning.

- Manually select the start line or wear a hole.

- Dynamic / static processing graphics, graphics zoom in / out, dynamic tracking cutting point under magnification

- DSP high speed, high precision interpolation control, high-speed operation, smooth running, low noise

- Set the start speed, acceleration and deceleration time with content

- Power off protection, breakpoint memory protection

- "offset cutting" function can avoid calculation errors, saving the materials.

- Management authority and the corresponding password can be set to maintain management rights

- Remote control of before and after, left, right and cutting movement, as well as start and stop function.

- Can be used for advertising plasma cutting machine,

- Walking frame function,

- Choice of the starting point.

Technical Indicators:

- Axis: 2 (can be customized for three axis)

- Control precision: ± 0.001mm

- Coordinate range: 99999.99mm

- The maximum pulse frequency: 200KHz; maximum speed: 15 m / min.

- Maximum program line number: 150000

- Largest single program: 6M

- Time resolution: 10ms

- Power supply: DC +24V DC power input

- System working environment: temperature -10℃ to +60℃; relative humidity 0-95% no condensation

System Interface:

- 15 core male two motor drive interface

- 25 core female head 16 photoelectric isolation output, the maximum reverse current 300mA

- 25 core male 16 isolated inputs, the maximum input current 300mA

- Front panel built-in USB interface, convenient user transmission cutting code

- Extension of IO input and output; PWM input port of the analog input port;

Hardware Configuration:

- Display: 7-inch high resolution 800*480 16000000 color high brightness LCD screen

- Memory: 2 64MSDRAM

- User space program: 256M

- 200MHZ system clock frequency

- USB: USB1.1 interface front

- Keyboard: electronic PCB film keyboard

- Case: whole steel structure completely shielded, can really achieve anti electromagnetic radiation, anti-static, anti-interference

F1510-T CNC Remote Control w/Receiver:

System Features:

- Up to 45 common graphic libraries

- Graphic scale, rotation and mirror image

-Graphic matrix, interlaced, repeated

-

According to the thickness of steel plate, speed limit can be

automatically set at the corner to effectively prevent over-burning

- Metric and imperial systems switching

- Graphic steel plate correction

- Customizable coordinate system

- Customizable IO

- System and parameter backup, and online upgrading

-

All Chinese/Foreign-language (English, Japanese, Russian, French, other

custom languages) operation menu. One button to switch between Chinese

and foreign languages.

- Line selection and numerical selection

- Support edge cutting and offset cutting

- With power-off, break-point protection memory function

- Dynamic/static processing graphic display, graphic enlargement/reduction, dynamic tracking cutting point in zoomed state

- Support for special nesting software such as Wentai, TYPEIII and PM2000

-

Encryption & decryption function: Different management rights and

corresponding passwords can be set to maintain the management's rights

and interests.

Wireless Remote Control Module Performance & Characteristics:

- 433MHz free ISM frequency channel, free license on trial

- Remote controlling 10mW, distance > 30m, at least not below 0.5m

-

Hardware test error code, software optimizing algorithm, bi-direction

communication, insure the communication stable and reliable

- Send module matches address with receive module, the address can be set manually, at most 128 supportable addresses

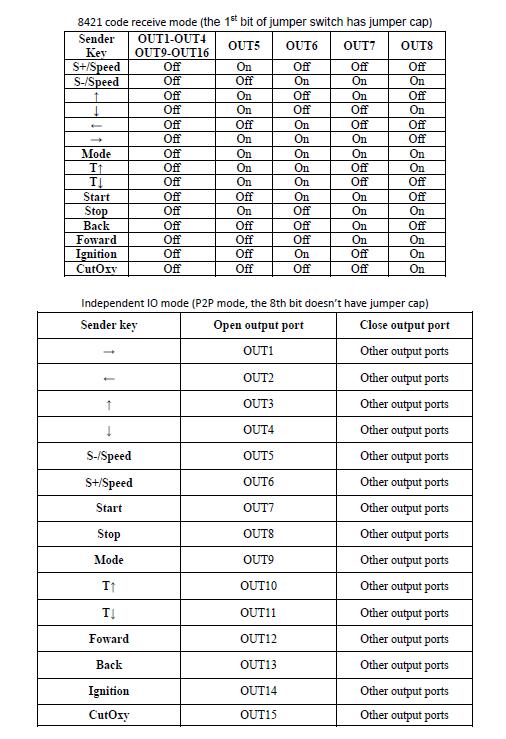

- Receiver module is set into 8421 port mode or P2P mode, at most 16 output ports

Interpretation of Jumper Switch:

1. Address segment

The first seven bits of jumper switch (No.1 -7) are address codes; the status of

this seven bits requires that sender and receiver must be same. If they are different,

receiver cannot reply.

Not: If open the sender, there is also a 8-bit jumper switch inside. Therefore in

the same time, 128 pairs of sender and receiver can simultaneously work at most.

2. Function select segment

The first bit of jumper switch is function select segment. When it is set to short

circuit, select 8421 code receive mode. When it isn't set to short circuit, select

independent IO port(P2P) receive mode.