| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $43.36 | $42.47 | $41.14 | $39.37 | Contact US |

G1009 10-inch Embedded HD Industrial Monitor 1024x768 Hook Mount TFT Display with BNC/VGA/AV/HDMI-compatible Ports

$109.57

G1009 10-inch Embedded HD Industrial Monitor 1024x768 Hook Mount TFT Display with BNC/VGA/AV/HDMI-compatible Ports

$109.57

G121SN01 V3 Color Active Matrix LCD Display Panel Designed for Various Industrial Applications

$88.42

G121SN01 V3 Color Active Matrix LCD Display Panel Designed for Various Industrial Applications

$88.42

RTU-307D NET-07D 8AI-8DI-8DO Data Acquisition Module IO Module (RS485+RS232) for Industrial Use

$76.89

RTU-307D NET-07D 8AI-8DI-8DO Data Acquisition Module IO Module (RS485+RS232) for Industrial Use

$76.89

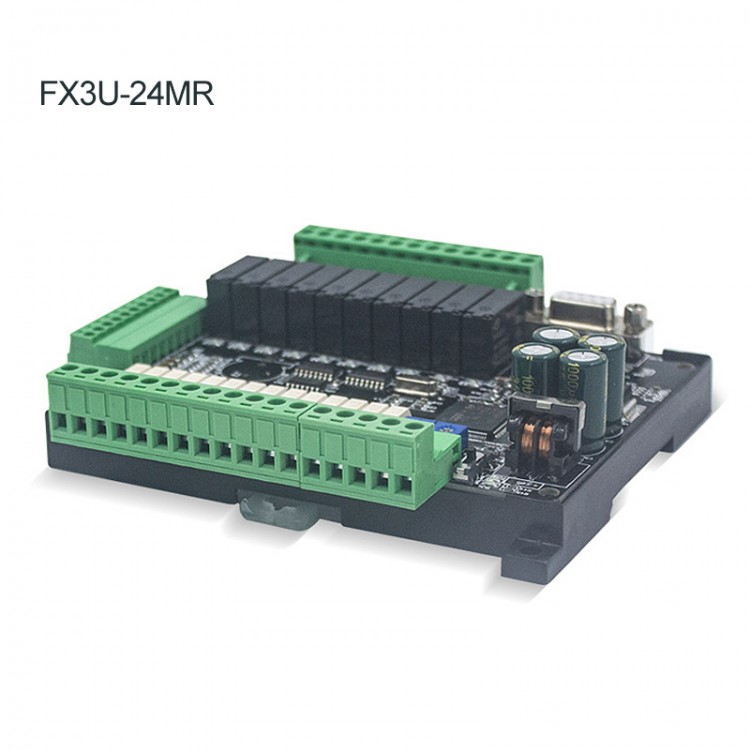

For Mitsubishi PLC Programmable Logic Controller FX3U-24MR High-Speed Input Output w/ 6 Analog Inputs

Features:

- FX3U-24MR industrial control board

- Original chip

- Stable performance

- Online Download

- Online monitoring

- MR Relay: Not support pulse. Can connect AC220 or DC 24V load. Output current up to 5A

- Can be used in various industrial automation control

- Suitable for metallurgy, printing, chemicals, plastics, building materials, home furnishing, packaging, textiles, food

Product Parameters:

- Product name: industrial control board

- Product model: FX3U-24MR

- Product number: 08900

- Output type: Relay output

- Input points: 14 points

- Output points: 10 points

- Supply voltage: 24V DC

- Output current: 5A

- Analog input: 6AD

- Analog output: 2DA

- High-speed counting: 6 channels 3K. Optional 6 channels 60K

- Pulse output: None

- Floating point: support

- Stepper motor: not supported

- Memory capacity: 8000 steps

- Download method: Direct download

- RS485 communication port: optional

- For MODBUS: optional

- Connect text screen: support

- Connect the touch screen: support

- Programming software: For GX Developer or GX Works2

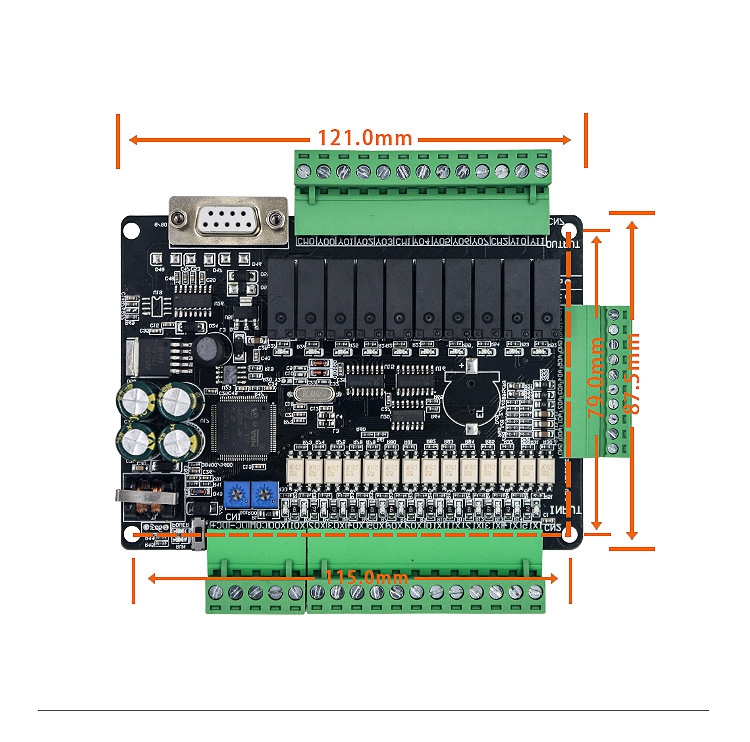

- Installation method: fixed isolation column installation

Soft Element:

- Intermediate relay M: M0-M3071, power-down storage range can be set M0-M1023

- Step point S: S0-1023, power-down saving range can be set to S0-S1023

- 100MS timer: T0-T199, accumulative power-down save T184-T199

- 10MS timer: T200-T249, accumulative power-off save T246-T249

- 1MS timer: T250-T383, of which T250-255 is cumulative

- 16-bit counter: C0-C199, save C100-199 when power off

- 32-bit counter: C200-C219, save C220-C234 when power off

- 32-bit high-speed counter:

C235-255; C235-240 is a single-phase counter without frequency multiplication;

C241-240 is a single-phase counter, 2 times the frequency;

C247-249 is a two-phase counter without frequency multiplication;

C250-252 is a two-phase counter, 2 times the frequency;

C253- is a two-phase counter, 4 times the frequency;

- Register D: D0-D7999, the saving range can be set to D0-7999 after power-off,

- Indirect addressing pointer V, Z: V0-7, Z0-7

- P subroutine jump number: P0-63

- I Interrupt: X0-5 external interrupt. Timer interrupt (1MS as a unit). The counter is interrupted.

- Special M element: M8000 is normally closed when running, M8002 is power-on pulse, M8011 is 10Ms pulse, M8012 is 100Ms pulse, M8013 is 1s pulse, and M8014 is minute pulse.

Instruction List:

Basic instructions:

LD: Normally open contact at the start of operation

LDI: Normally closed contact at the start of operation

LDP: Rising edge detection operation starts

LDF: Falling edge detection operation starts

AND: series normally open contact

ANI: Series normally closed contact

ANDP: Series connection detected on rising edge

ANDF: Falling edge detection of series connection

OR: Parallel normally open contacts

ORI: Parallel normally closed contacts

ORP: parallel connection detected by rising edge

ORF: Falling edge detection parallel connection

ANB: Series connection between circuit blocks

ORB: parallel connection between circuit blocks

OUT: Coil output drive

SET: keep the coil action

RST: Release the coil operation hold

PLS: Coil rising edge output

PLF: Coil falling edge output

ALT: alternate output

MC: Coil for common string connection point

MCR: Common contact release command

MPS: Operational storage

MRD: storage read

MPP: memory read and reset

INV: Invert the result of the operation

END: end of program

STL: start of step ladder diagram

RET: End of step ladder diagram

CALL: call subroutine

SRET: Subroutine return

Procedure Flow Chart:

CJ: Conditional jump

CALL: subroutine call

SRET: Subroutine return

FEND: End of main program

Send and Compare:

CMP: Comparison

ZCP: Regional comparison

MOV: transfer

CML: Reverse transmission

BMOV: send together

FMOV: Multicast

XCH: Exchange

BCD: BCD conversion

BIN: BIN conversion

Four Logical Operations:

ADD: BIN addition

SUB: BIN subtraction

MUL: BIN multiplication

DIV: BIN division

INC: BIN plus 1

DEC: BIN minus 1

WAND: logical word and

WPR: logical word or

WXOR: logical word exclusive OR

NEG: complement

Cycle Displacement:

ROR: right shift cycle

ROL: Shift left loop

RCR: right shift

RCL: Left shift

SFTL: bit shift left

SFTR: bit shift right

Special Components Instruction:

M8000: Normally closed during operation

M8002: Power-on pulse

M8011: 10Ms pulse

M8012: 100Ms pulse

M8013: 1s pulse

M8014: is the minute pulse

ZRST: Batch reset

MEAN: Average

FLT: BIN, integer → 2, hexadecimal floating point number conversion

GRY: BIN, integer → gray code conversion

GBIN: Gray code → BIN, integer

DHSCS: High-speed comparison set

DHSCR: High-speed comparison reset

SPD: Pulse density, pulse width (pulse interval time) can also be measured

PLSY: Pulse output

PLSV: Pulse output with direction control

PWM: Pulse width modulation, 0-32767us

PLSR: Pulse output with acceleration and deceleration

DRVA: Absolute position control

DRVI: Relative position control

ABSD: Cam control (absolute method)

RS: Serial data transmission

ASCI: HEX-ASCII conversion

HEX: ASCII-HEX conversion

CCD: check code

PID: PID calculation

SEGD: BCD to 7-segment digital tube

ECMP: Comparison of binary floating-point numbers

EZCP: Interval comparison of binary floating point numbers

EBIN: decimal floating point number-2, conversion of decimal floating point number

EADD: Addition of binary floating-point numbers

ESUB: binary floating-point number subtraction

EMUL: Binary floating point number multiplication

EDIV: Division of binary floating-point numbers

INT: Binary floating point number -BIN, integer conversion

SIN: floating-point number SIN operation

TAN: Floating point number TAN operation

COS: Floating point COS operation

ASIN: floating-point number SIN-1 operation

EXP: binary floating point exponential operation

LOGE: natural logarithm operation of binary floating-point numbers

LOGE10: Commonly used logarithmic operations of binary floating-point numbers

SWAP: Up and down byte conversion

SER: data search

ALT: alternate output

RAMP: ramp signal

BON: ON bit judgment

SUM: ON digits

ANS: Alarm set

ANR: Alarm reset

HOUR: Chronograph

TCMP: Clock data comparison

TRD: Clock data read

TWR: clock data write

LD=: (S1=(S2)

LD>: (S1)>(S2)

LD<: (S1)<(S2)

LD◇: (S1)≠(S2)

LD≤: (S1)≤(S2)

LD≥: (S1)≥(S2)

AND=: (S1=(S2)

AND>: (S1)>(S2)

AND<: (S1)<(S2)

AND◇: (S1)≠S2)

AND≤: (S1)≤(S2)

AND≥: (S1)≥(S2)

OR=: (S1=(S2)

OR>: (S1)>(S2)

OR<: (S1)<(S2)

OR◇: (S1)≠(S2)

OR≤: (S1)≤(S2)

OR≥: (S1)≥(S2)

Package Included:

- 1 x PLC Controller

Note:

- It is the version only with bare board. If you need a base, a shell, RS485 function, or a clock, please contact us to pay extra money when purchasing.

- Programming cable is not included. Please purchase separately.

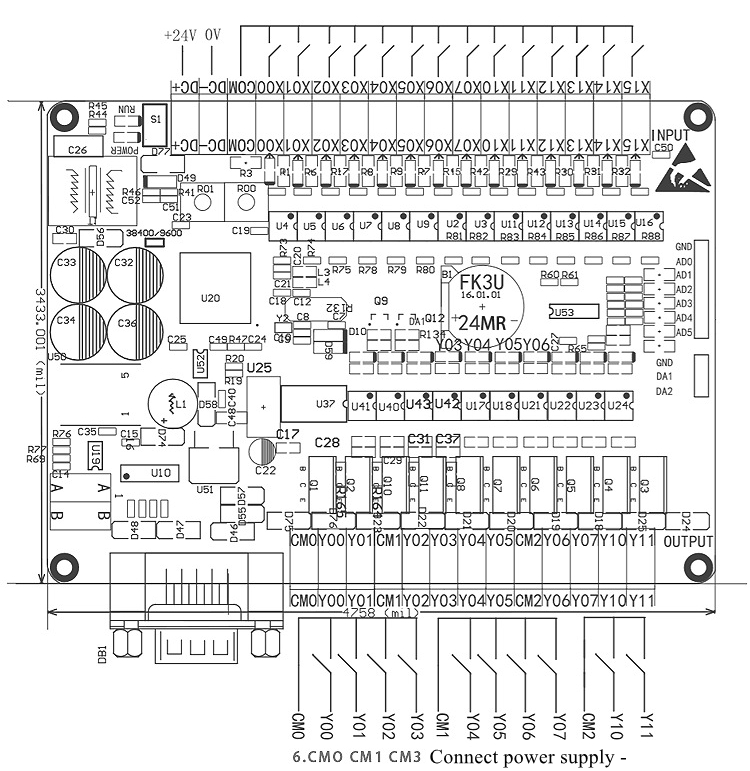

Wiring Diagram:

1. DC-: The power input is connected to the negative pole of the 24V switching power supply

2. DC+: The power input is connected to the positive pole of the 24V switching power supply

3. COM: input common terminal, low level

4. X0~X15 inputs are all active low and can be connected to NPN series sensors

5. X0~X5 can be used as high-speed counters. The default is up to 12K, optional 100K, supports 3 AB encoders and C251, etc.

How To Fix:

The installation method of the panel PLC: The installation method of fixed rubber particles on the drilling hole is used. Each PLC board has holes on the four corners for fixing installation holes, and each board is equipped with 4 PLC board isolation columns.

Application Example: