| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $116.69 | $114.31 | $110.74 | $105.97 | Contact US |

RT-Thread RK3506B Commercial Grade Core Board 256MB DDR+256MB Flash Support for Linux/Ubuntu/OpenEuler

$25.28

RT-Thread RK3506B Commercial Grade Core Board 256MB DDR+256MB Flash Support for Linux/Ubuntu/OpenEuler

$25.28

RT-Thread RK3506J Industrial Grade Core Board 256MB DDR+256MB Flash Support for Linux/Ubuntu/OpenEuler

$29.68

RT-Thread RK3506J Industrial Grade Core Board 256MB DDR+256MB Flash Support for Linux/Ubuntu/OpenEuler

$29.68

RT-Thread RC-Pi-3506 Industrial Development Board Kit with 7-inch MIPI Screen + Power Adapter + USB-TTL Module

$123.69

RT-Thread RC-Pi-3506 Industrial Development Board Kit with 7-inch MIPI Screen + Power Adapter + USB-TTL Module

$123.69

RT-Thread RC-Pi-3506 Industrial Development Board Kit with 7-inch 1024x600 MIPI Screen Support for Linux/Ubuntu/OpenEuler

The development experience of MCU and the performance release of MPU:

- One-stop IDE: one-stop system configuration, development, compilation, and download; Support for JLINK hardware debugging; Support multi-core SMP debugging.

- Graphic platform configuration: CPU, PIN reuse, interrupts, clock, DMA, and various peripheral configurations can all be completed through a graphical interface.

Hard real-time kernel level assurance, empowering industrial precision upgrades:

- The EtherCAT master station supports 32-axis synchronization with a synchronization period of <250μs. The jitter is <+/-5us, which meets the high-precision control scenarios of industrial automation.

- High load scenario optimization ensures strong hard real-time performance even in high load scenarios through innovative CPU isolation strategies, intelligent interrupt/thread binding technology, and deeply optimized network stacks and I/O subsystems.

SMP Multi-core Development:

- Realize resource isolation and efficiency doubling, simplify multi-core programming, support real-time task exclusive core, and improve system performance.

- One click allocation of peripheral interrupts to designated cores using graphical tools to avoid resource conflicts.

- Based on the JTAG/SWD interface, achieve multi-core synchronous debugging and support cross core breakpoints.

- Automatic core binding (real-time tasks monopolize real-time cores) + dynamic load balancing, increasing CPU utilization by 30%.

Full Stack Industrial Protocol Support:

- Supports for EtherCAT, Modbus, CANOpen, OPC-UA and other mainstream industrial protocols.

- Provide EtherCAT main station configuration tool: site information management, main station information display and configuration, DC clock configuration, site status and abnormal information display, PDO data configuration.

Hybrid Deployment Intelligent Upgrade:

- Support the simultaneous deployment and operation of RT Thread + Linux on a single chip, with the Linux version supporting for Buildroot, Ubuntu, OpenEuler Embedded.

- In hybrid deployment mode, it supports efficient communication between dual systems, including RPMSg, virtual serial port, virtual network card, remote system call, NFS network file system, and other mechanisms.

Functions:

- High speed signal acquisition: supports data acquisition in multiple fields such as industrial vibration, audio, and power monitoring.

- Ultimate real-time control: task switching <1μs. Interrupt delay <2.5μs, cycle jitter <5μs; PWM control accuracy of 50ns ~ 2μs, EtherCAT32 axis synchronization period <250μs.

- Multi-core collaborative scheduling: Isolate scheduling tasks such as EtherCAT and control algorithms to ensure real-time performance.

- UI human-machine interface: supports lightweight LVGL and full-featured QT framework, adapted to different device requirements.

- Full stack network communication: covering Ethernet, 5G/WiFi, supporting IEEE1588 clock synchronization and MQTT/Modbus protocols.

- AI reasoning collaboration: RT Thread runs real-time control, integrates NPU on Linux, and supports large-scale model deployment on the side.

Applications:

- Industrial Internet: equipment remote monitoring, predictive maintenance, intelligent transmitter network.

- Logistics automation: AGV multi vehicle scheduling, dynamic obstacle avoidance for warehouse robots.

- Intelligent manufacturing: discrete control, process control, robot multi-axis collaboration, CNC precision machining.

- Smart city: intelligent digital control, drone control, intelligent traffic signal control, street lamp cluster management.

- Energy and electricity: distribution terminal detection, energy storage system control, photovoltaic inverter cluster management.

- Medical equipment: real-time control of surgical robots.

Solutions:

- Power FTU/DTU/Protection Solution

- CNC Controller Solution

- HMI Solution

- EtherCAT Controller Solution

- Industrial Gateway Solution

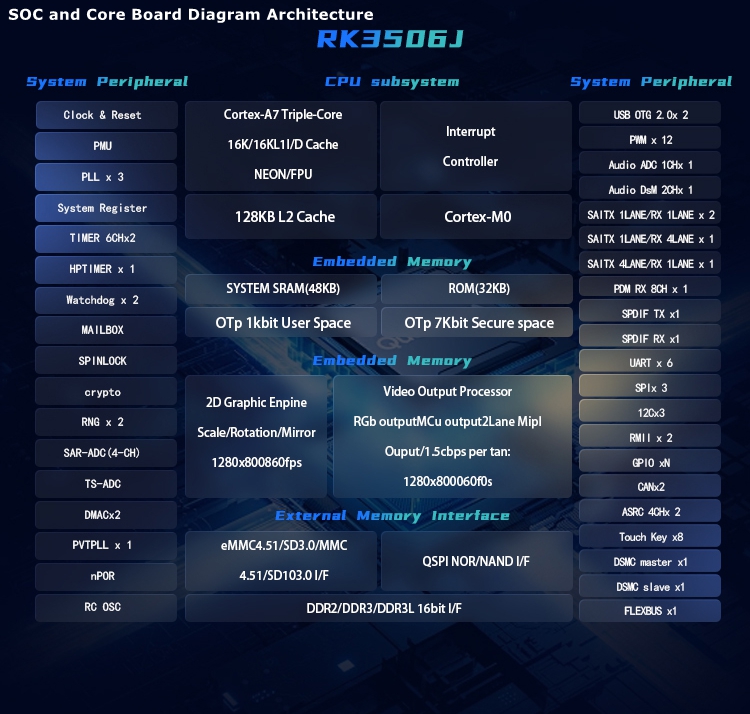

Core Board Parameter:

- SOC: for RockChip RK3506J

- CPU: three-core Cortex-A7 + single-core Cortex-M10, master frequency up to 1.5GHz

- GPU: 2D Graphic Engine

- Memory: 256MB DDR3/DDR3L 16bit

- Storage: 256MB NAND, with 1 x TF Card slot

Hardware Parameter:

- Ethernet: support dual 100Mbps Ethernet

- Wireless network: support 4G LTE Cat1 mobile communication, support 2.4GHz WLAN

- Display interface: video output: 1 x MIPI_DSI_TX (2Lane Output/1.5Gbps per Lane, 1280 x 1280 at 60fps)

- Audio interface: 1 x Speaker, mono speaker output; 1 x LINEIN; 1 x LINEOUT; 1 x MIC

- USB: 1 x USB2.0 OTG; 1 x USB2.0 HOST

- Expansion interface: 1 x SWD Debug; 2 x UART TTL; 1 x RS485; 1 x CAN; 2 x I2C

- Board size: 120 x 85mm

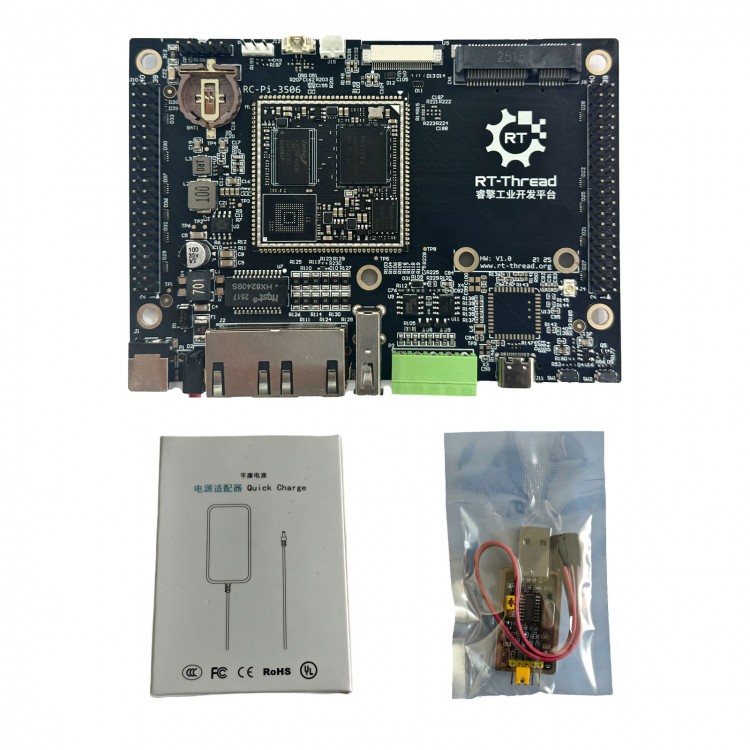

Package Included:

- 1 x Development Board

- 1 x Core Board

- 1 x Antenna

- 1 x Debugging Adapter Board

- 1 x Copper Column

- 1 x 5P Terminal

- 1 x 7-inch 1024x600 MIPI Screen