| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $257.26 | $252.01 | $244.13 | $233.63 | Contact US |

HSCanT 8Mbps High Speed USB to 4-Channel CAN FD Tool HPM5321 Support for SLCAN and GS USB Protocols

$47.82

HSCanT 8Mbps High Speed USB to 4-Channel CAN FD Tool HPM5321 Support for SLCAN and GS USB Protocols

$47.82

PX Logic 32 32-Channel 1GHz 4G Storage USB3.0 Super High Speed Logic Analyzer with Accessory Kit

$220.81

PX Logic 32 32-Channel 1GHz 4G Storage USB3.0 Super High Speed Logic Analyzer with Accessory Kit

$220.81

PX Logic 16 Pro 16-Channel 1GHz 4G Storage USB3.0 Super High Speed Logic Analyzer with Accessory Kit

$143.08

PX Logic 16 Pro 16-Channel 1GHz 4G Storage USB3.0 Super High Speed Logic Analyzer with Accessory Kit

$143.08

UTA0503 CAN & LIN Analyser USB To CANFD LIN PWM K Protocol Support DBC LDF Electromagnetic Isolation

Download Materials:

- Download software: http://www.toomoss.com/download/7-cn.html

- Download help document: http://www.toomoss.com/download/2-cn.html

- Download source code of secondary development example program: http://www.toomoss.com/download/4-cn.html

- Download CAN Bootloader source: https://github.com/usbxyz/CAN-Bootloader

- PC software function description: http://www.toomoss.com/news/32-cn.html

Features:

- Support CANFD and LIN1.0~2.2 data communication at the same time. At the same time, it supports high-speed USB to CANFD, CAN2.0A/B, LIN functions, and supports the CANFD standard for ISO/Bosch. Compatible with CAN2.0A/B mode transceiving, the maximum baud rate of the data domain can be configured to 8Mbps, and the maximum data length can be configured to 64 bytes. It can provide 40 times higher data load than CAN2.0A/B. The LIN interface can also be used as USB to PWM and USB to K_LIN functions. In addition, it also supports CAN/LIN mutual conversion and offline CAN/LIN data transmission.

- High-performance processors can easily cope with various harsh requirements. It adopts a high-performance processor with a running frequency of 168MHz and comes with a large-capacity data buffer, which can handle big data real-time interaction and ensure no frame loss. Using 480Mbps double-buffered USB data transmission technology, it can simultaneously deal with dual-channel 8Mbps CAN data transmission and reception and dual-channel 20Kbps LIN data transmission and reception.

- Up to 3000VDC electromagnetic isolation to avoid interface damage. CAN LIN12V outputs are all equipped with 3000VDC electromagnetic isolation (only for versions with isolation). It can effectively avoid backflow damage caused by the different ground potentials of different nodes. All interfaces are equipped with overcurrent protection, overvoltage protection, and reverse connection protection. It can cope with a variety of complex use environments and ensure the stability and reliability of the hardware.

- Integrating multiple functions into one, it can easily deal with various test developments. CAN can be used in automotive electronics, rail transit, medical electronics, industrial automation and other occasions. LIN is mainly used in automotive electronics (car lights, car windows, car ambient lights, car air conditioners). PWM can be used for motor speed control and LED brightness adjustment. CAN/LIN mutual conversion can be used to connect CAN/LIN network data forwarding. USB to CAN, USB to LIN, USB to K, USB to PWM, CAN to LIN.

- Unlimited data storage, no frame loss. The adapter has up to 56 frames of hardware buffer for CANFD per channel, and up to 128 frames of hardware buffer for LIN per channel, which can effectively resist the impact of high bus load and ensure that CAN/LIN messages do not lose frames. The software adopts file buffer technology, and automatically saves the data after receiving the data. The number of data frames that the software can receive depends on the size of local hard disk space.

- Support vehicle-mounted DBC/LDF protocol analysis and DBC/LDF transmission. Users can load the DBC/LDF file of the vehicle or parts, analyze the application protocol, and directly control the vehicle through DBC/LDF to send related instructions, which is convenient for the whole vehicle to test and repair the vehicle parts.

- Supports message playback and drawing variable curve functions. After the monitored CAN/LIN data can be saved as a file, the data can be played back through the software. And can load the DBC/LDF file to carry on the curve analysis of the variable. If there is no DBC/LDF file, you can also manually add custom variables for curve analysis.

- Support CAN relay, CAN/LIN mutual conversion. CAN supports the relay function, which can capture the data received and sent by the device without affecting the normal operation of the device. CAN/LIN mutual conversion supports mutual conversion between online mode and offline mode, and a variety of conversion rules can be set to meet various needs of applications.

- Support CAN/LIN firmware upgrade function. Support CAN Bootloader (CAN firmware upgrade) function of STM32F1/2/4 series and TMS320F28335/2808. Provide free MCU side and host computer side source code, provide STM32F 103 LIN firmware upgrade source code, which can be directly applied to the user's product to achieve product firmware upgrade. Online upgrade of the device firmware on the CAN/LIN bus.

- The product firmware is permanently upgraded for free. If the adapter adds new functions or solves a known problem, the user can upgrade the internal firmware of the adapter with one click to solve the possible problems with the adapter firmware. Upgrade adapter firmware online.

- Efficient and easy-to-use secondary development interface functions. Provide secondary development library, which can support various development environments and languages, for VC, VB, C#, Labview, LabWindows, Delphi, Java, Python and other mainstream development environments. Interface functions support for Windows, Linux (including desktop and embedded systems) ), Mac OS, Android system, each language provides multiple sample program source code for reference, efficient and easy to use. Source code package of secondary development example program.

Detailed Function Introduction:

1. CAN Bus Related:

- Support 2-channel CANFD CAN 2.0A/B, built-in CAN transceiver, can be directly connected to CAN bus for data monitoring and sending and receiving;

- Baud rate range is 10Kbps~8Mbps, multiple baud rates are directly selectable in the software, and any baud rate can be customized. A single frame data field can transmit up to 64 bytes of data;

- Built-in 120Ω terminal resistance, which can be connected or not connected to the bus under software control;

- The interface is equipped with over-current and over-voltage protection, which can protect the internal chip from damage to the greatest extent;

- Support offline CAN data transmission function, only need to use software for TCANLINPro to write data into the adapter, the adapter can automatically send the written CAN data after being powered by the USB charger;

- Offline transmission mode can also connect one of the LIN buses to a key switch to trigger data transmission;

- Support CAN relay function, without affecting the normal operation of the original device, collect the CAN bus data received and sent by the device, the CAN relay function can be used offline/offline;

- Use powerful software for TCANLINPro, support unlimited CAN data monitoring and recording, data playback, data filtering, data update display, list mode to send and receive data, data waveform display, support for data analysis and data sending and receiving through DBC files;

- Using the software for TCANLINPro, the collected CAN bus data can be played back;

- Multiple sending data list files can be displayed on the same interface, click the corresponding icon to send the corresponding list data.

2. LIN Bus Related:

- Supports up to 2 channels of LIN1.0~2.2, built-in LIN transceiver, can be directly connected to LIN bus for data monitoring and sending and receiving, LIN bus supports master or slave mode;

- The baud rate range is 2Kbps~100Kbps, the baud rate can be configured arbitrarily, and the existing bus baud rate can be automatically detected;

- After being configured as the host mode, it will automatically connect to the internal 1K pull-up resistor, and the internal 5V to 12V power supply, without external 12V power supply. The 12V output can supply power to external devices, and the maximum power supply current is 100mA;

- LIN interface and 12V interface have built-in over-current and over-voltage protection, which can protect the internal chip from damage to the greatest extent;

- If you need to use a LIN bus with other voltages, such as a 24V LIN bus, you only need to connect an external 24V voltage to the 12V output interface;

- Support offline LIN data transmission function, only need to use the software for TCANLINPro to write data into the adapter, the adapter can automatically send the written LIN data after being powered by the USB charger;

- Offline sending mode can also connect one of the LIN bus lines to a key switch to trigger sending data;

- Use powerful software for TCANLINPro, support unlimited LIN data monitoring and recording, data playback, data filtering, data update display, list mode to send and receive data, data waveform display, support for data analysis and data sending and receiving through LDF files;

- LIN supports master mode and slave mode. In master mode, the synchronization interval signal and frame header signal can be sent separately. In slave mode, the specified ID can be configured to send data to the bus after receiving the frame header;

- While sending data in LIN master mode, it also monitors and receives the data on the LIN bus. The received data can be used to judge whether the data is sent correctly (a very important function);

- Using the software for TCANLINPro, the collected LIN bus data can be played back;

- Supports firmware programming of MLX81106/MLX81109 (LIN bus interface ambient light chip) and other series of chips, and automatically tests the firmware program functions;

- You can display multiple sending data list files on the same interface, and click the corresponding icon to send the corresponding list data.

3. PWM Related:

- The LIN bus interface can also be used as a PWM signal output. The 2-channel LIN bus can output 2-channel PWM signals at the same time, and the phase, frequency, and duty cycle can be adjusted by software;

- The PWM port can also detect PWM signals, the detection frequency range is 20Hz~100KHz, and the frequency and duty cycle can be measured;

- The default PWM output voltage is 12V, you can turn off the 12V output by software, and connect to the 12V output port;

- Voltage, so that PWM waveforms of other voltages can be output;

- The PWM waveform output frequency is 1Hz~100KHz, and the duty cycle accuracy can be set according to actual needs.

4. K Bus Related:

- According to the K-bus protocol, a set of K-bus transceiver functions are encapsulated, and these functions can be called to realize the K-bus data transmission and reception.

5. Other Instructions:

- The adapter with electromagnetic isolation version has 3000VDC electromagnetic isolation inside, which can effectively avoid backflow damage caused by the different potentials of different nodes;

- It adopts a high-performance processor with a main frequency of 168MHz, and a large-capacity RAM inside, which can simultaneously deal with dual-channel 1Mbps CAN data transmission and reception and dual-channel 20Kbps LIN data transmission and reception;

- Use full-speed 12Mbps USB to transmit data, and the bottom layer adopts double buffering technology, which can effectively avoid frame loss during large data transmission;

- For TCANLINPro software can control multiple devices at the same time, multiple channels work at the same time, the data is cached in file mode, and CAN/LIN data can be captured and recorded without limitation;

- The software supports the update display function of the same ID data, and supports the statistics function of the same ID frame number, which is convenient for analyzing the changed data;

- Support CAN/LIN bus online conversion or offline conversion, only need simple configuration on the software;

- Support the CAN Bootloader (CAN firmware upgrade) function of the STM32F1/2/4 series and TMS320F28335/2808, provide the source code of the MCU and the host computer for free, and provide the source code of the STM32F103 LIN firmware upgrade, which can be directly applied to your own products to realize the product Firmware upgrade;

- Provide a secondary development library, which can support various development environments and languages, for VC, VB, C#, Labview, LabWindows, Delphi, Java, Python and other mainstream development environments, and interface functions support for Windows, Linux (including desktop and embedded systems) ), Mac OS, Android system, each language provides multiple sample program source code for reference, efficient and easy to use;

- If the adapter adds new functions or solves a known problem, the user can upgrade the internal firmware of the adapter with one click. Solve the worries that there may be problems with the adapter firmware;

- Provide permanent technical support. As long as we purchase our equipment, we provide strong technical support.

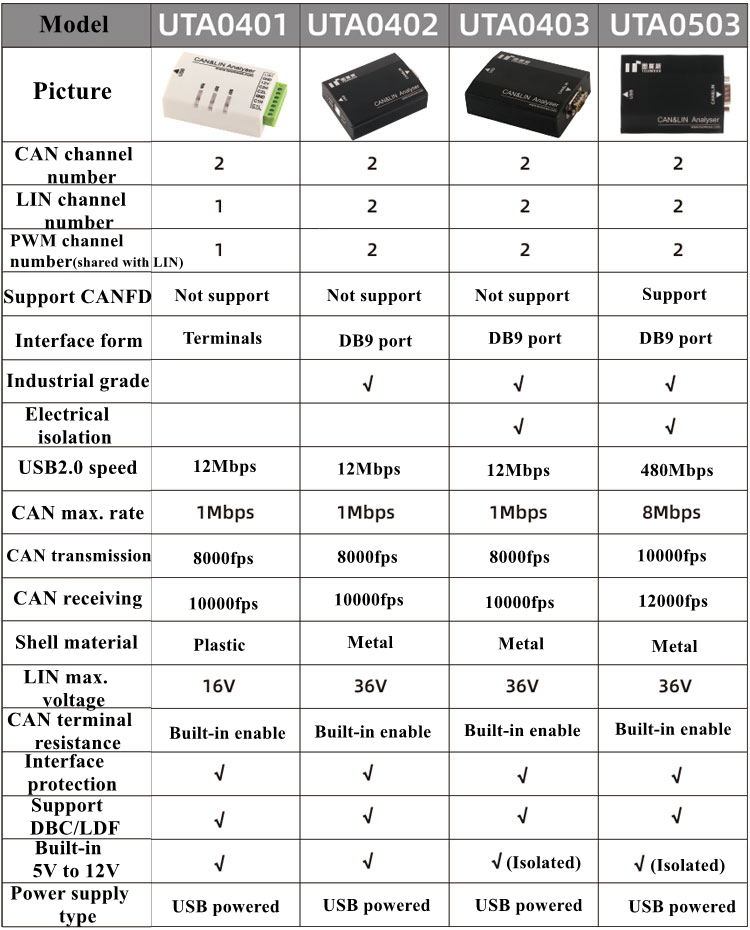

Specifications:

- Model: UTA0503

- Interface type: USB

- Category: Metal case isolation version (UTA0503)

- Applicable scenarios: automotive electronics

- Size: 90x60x20mm

Package Included:

- 1 x Set of CAN & LIN Analyzer