| Quantity | 3+ units | 10+ units | 30+ units | 50+ units | More |

|---|---|---|---|---|---|

| Price /Unit | $21.99 | $21.54 | $20.87 | $19.97 | Contact US |

Finished HiFi Preamplifier Board DIY Audio Amplifier Board Replacement for Marantz HDAM Classic Preamplifier

$32.62

Finished HiFi Preamplifier Board DIY Audio Amplifier Board Replacement for Marantz HDAM Classic Preamplifier

$32.62

Line Magnetic Audio LM-508IA 48W+48W Tube Amplifier Integrated Amplifier Tube Amp with Two VU Meters

$2,624.45

Line Magnetic Audio LM-508IA 48W+48W Tube Amplifier Integrated Amplifier Tube Amp with Two VU Meters

$2,624.45

2x80W HiFi Digital Power Amplifier Board V1.6 Class D Amplifier Board for MERUS MA12070 with Toggle Switch

$33.44

2x80W HiFi Digital Power Amplifier Board V1.6 Class D Amplifier Board for MERUS MA12070 with Toggle Switch

$33.44

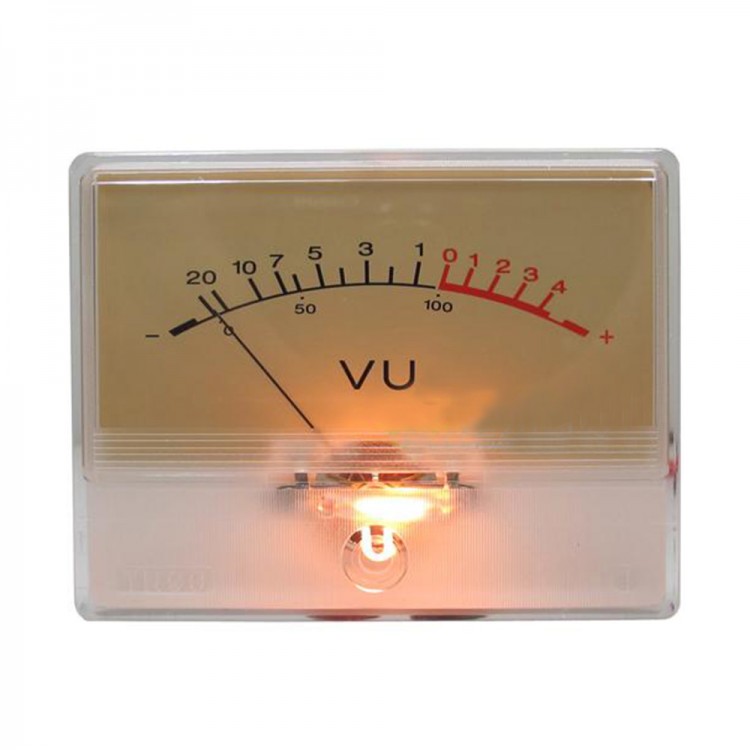

VU Meter for DB Level Headphone Amplifier Chassis Audio Preamp with Backlight T-90

Description:

- Pointers Material:Zinc and copper-nickel alloy

- Pointer color:black

- The direction of the pointer swing : left to right

- Pointer length : 44± 1 mm from the center axis to the needle end

- Pointer width : 0.45 ± 0.05 mm

Features:

- Standard test conditions temperature: 20 ℃, humidity 70% . Can also be tested under normal temperature and humidity

- The influenza degree pointer at the zero scale to the maximum scale sensitivity of 960uA ± 8% (full scale position) internal impedance :650Ω ± 10%

- Insulation impedance meter outside the box plus the electrical circuit with 500V DC plus 50M ohm meter shell

- Electrical insulation of the circuit impedance is 500V DC voltage test of the insulation value. Pointer to overlap with the zero-scale tolerance of ± 1mm balanced meter using a standard position and tilt 90 degrees to allow the error range of ± 1mm pointer to mount the current instant plus three times the full scale current, and slowly reduced to the the electric influenza degree 1/2 reading,

- The pointer will return to the scale plate within 1/3 scale friction meter coupled with the current, and slowly increase or decrease to a certain value, indicating the point of error range of ± 1mm,brake instantly plus scale plate 2/3 of the current value of the pointer indicates the location of the time required for a second or less.

Special test:

- Tests on each interval of five seconds to ten times the full scale current input overload, the action is repeated nine times for each time of 0.5 seconds.After this test, 7-14 to maintain normal.

- Vibration test meter packaged in the vibration plate 1,000 times per minute, up and down 4mm shock In each direction for 10 minutes. After this test 7-14 to maintain normal impact test meter packaged 30-cm height of fall in 3cm thick wooden board, XYZ three-direction test.After this test, 7-14 to maintain normal reliability test the current input of 100,000 calibration points within the limits of current sense is still the standard environmental impact test temperature of 50 ° C, humidity 85%, for 100 hours, after this test 7-14 to maintain normal.

- Terminal pull test :terminals must withstand one kilogram tension, sustained 60 seconds will not be affected

Others:

- Temperature limits for using:-10 ℃ to +60 ℃ RH 35 to 85%

- Temperature limits for Storage:-20 ℃ to +60 ℃ RH 35 to 85%

- Soldering Condition terminal about 3 mm placed in the temperature of 230 ℃ tin plate, placed 3.5 seconds.

- After this test, 7-14 to maintain normal,

- Hand-held soldering gun to solder temperature 350 ℃, the terminal contact for 3.5 seconds, the terminal front-end of about 3mm contact with the solder gun.

- After this test, 7-14 to maintain normal,anti-static test in the same direction three times, to characterize the difference between the pointer in the length of the scale in a transparent cover surface to dry nylon 1/3 back to the zero position.

Package list:

- 1 x VU Meter